|

|

CNC five-axis tool grinder is suitable for the following tools:

1. Milling tools: including end mills, ball end mills, step drills, reamers, etc.

2. Drilling tools: such as drill bits, forming step drills, etc.

3. Forming tools: such as forming milling cutters, deep hole drills, triangular chisels and planer tools, etc.

4. Non-standard tools: suitable for the production or grinding of tools of various special shapes and sizes.

5. Medical tools: due to its high precision and flexibility, it is also suitable for precision tool manufacturing in the medical industry.

Shanghai ANTS Machine CNC five-axis tool grinder is widely used in the manufacture and grinding of various tools with its high precision, high efficiency and intelligent characteristics, especially in the field of tool processing with complex shapes and high precision requirements.

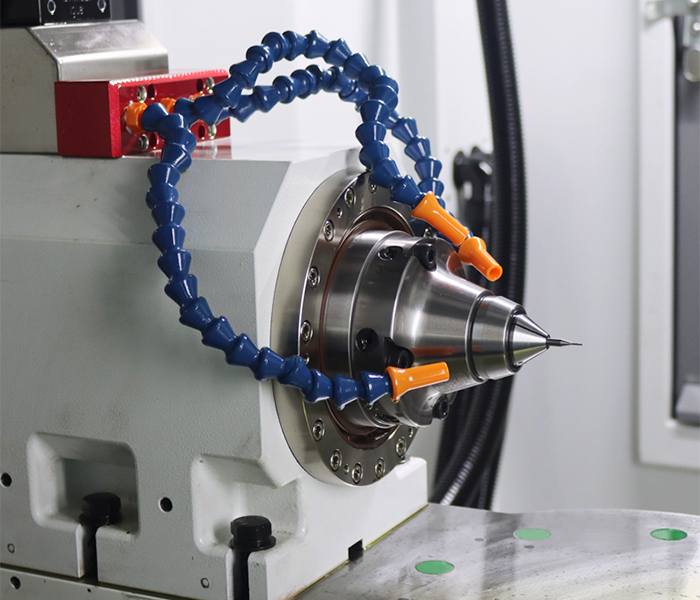

1. High precision and high rigidity: Five-axis tool grinders can achieve high-precision processing, which is essential for manufacturing high-performance and high-value-added professional tools. The machine tool is equipped with linear/direct drive motors, covering multi-dimensional disciplines such as linear axis servo control technology and precision measurement technology, ensuring the superior performance and working accuracy of the machine tool.

2. Five-axis linkage: The five-axis linkage function enables the machine tool to achieve precise grinding on complex geometric shapes and meet diverse process requirements. This linkage design enables the machine tool to complete the grinding of multiple surfaces in one processing process, improving processing efficiency and accuracy.

3. High efficiency: The five-axis tool grinder effectively improves the grinding efficiency and processing accuracy of the work-piece through new structural mechanisms and various vibration absorption and temperature rise resistance treatments.

4. Intelligent technology application: Equipped with laser probes, grinding wheel probes, sonar sensors, CCD cameras, etc., it has machine tool status monitoring and optimization, dynamic and thermal automatic compensation, anti-collision function, tool processing on-machine detection, grinding wheel online automatic grinding calibration and dynamic balancing, etc., which improves the intelligent level of tool grinding.

5. High-speed performance: The processing form of CNC tool grinders is mainly high-speed and high-precision form grinding. The application of super-hard material grinding tools such as diamond grinding tools and CBN grinding tools puts forward new requirements for the high-speed performance of grinding machines. For example, the grinding wheel axis generally adopts an electric spindle with a speed of more than 10,000 r/min.

6. Flexibility of work-piece size: Five-axis CNC machine tools can adapt to work-pieces of various sizes, from small precision parts for medical applications to large parts for the automotive or aerospace industries. The flexibility of work-piece size is very large.

7. Safety and collision avoidance: The design of five-axis CNC machine tools ensures that even if the work-piece is large, the tool can still approach it from multiple angles, thereby making full use of the five-axis function while reducing the risk of collision.

CNC five-axis tool grinder, tool grinder, grinding wheel dresser, tool grinding overall solution.For more information, please consult www.antsmachine.com or send an email to contact@antsmachine.com