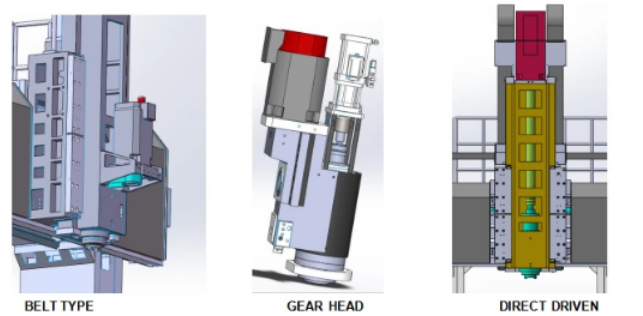

There are several types of spindles that can be used in CNC machining centers. The common ones are belt type spindles, direct driven spindles, and gear head spindles.

1. Belt types spindle

The belt-type spindle uses a belt to transmit the movement of the spindle motor to the spindle. Its advantages are that the vibration is smaller than that of the gear head spindle and it is easy to assemble. The disadvantages are that the noise is high at high speed and the belt tension is not easy to control.

Belt-type spindles are used in both small CNC machining centers and large CNC machining centers, and can process large workpieces as well as small parts.Large-scale vertical CNC machining centers spend most of their time doing heavy cutting, processing cast iron and steel castings, and mold processing. Belt-type spindles are competent in this regard, but some alloys with high hardness are not suitable for belt-type spindles. Instead, gear-head spindles are selected.

2. Direct driven spindle

Direct driven spindle: The direct driven spindle is similar to the engagement method of a three-axis motor and a ball screw. The spindle motor is placed above the spindle. The motor and the spindle are connected by a high-rigidity gap-free coupling. The rotation of the motor end is transmitted to the spindle through the coupling, which is the direct-connected spindle.

The direct driven spindle is a rigid connection. The power supply output from the motor can be fully expressed in the characteristics of the spindle and the mechanical efficiency is higher. When the spindle is moving, the coupling plays an indispensable role. The coupling is corrected well or badly enough to affect the accuracy of the spindle movement. If the coupling is not corrected well, it will have the following effects on the spindle. The temperature rise of the spindle is sharply increased, the spindle vibration is too large, the spindle yaw is too large, the machining accuracy is poor, and even the spindle is burned.

Gear-type spindle: The biggest advantage of gear-type spindle is that it can transmit high torque and has excellent heavy-cutting ability. Its disadvantage is that the speed is limited by the gear design and it is not easy to improve.

Shanghai ANTISHICNC machining centers mostly use belt-type spindles as standard, and direct-linked spindles as optional.Like large machining centers VMC1060, 1160, 1275, etc., and small machine center VMC850, 650, 450, etc., they are all cost-effective CNC machining centers, which are widely praised by customers.

Tags: CNC machine center , vertical machine center,Belt types spindle,direct driven spindles, gear head spindles.