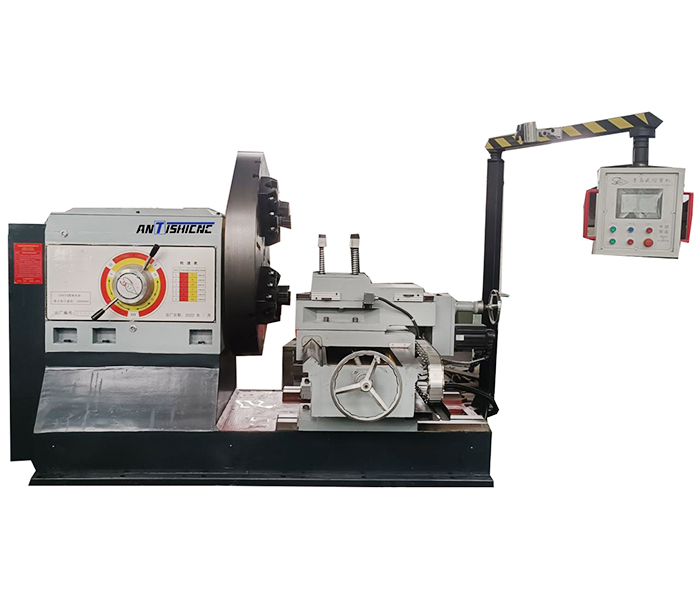

Model:C6061

Technical parameter

| Name | Unit | Specifications |

| C6061-PLC model | ||

| Max. Swing dia. over Bed | mm | Φ1600 |

| Max. Workpiece weight | kg | 1500 |

| Max. Workpiece length | mm | 500 |

| Chuck diameter | mm | 1200 |

| Spindle front bearing diameter | mm | 180 |

| Spindle speed | r/min | 20~250 |

| Spindle level | – | 6 levels |

| Longitudinal feed level | – | electrodeless |

| Transverse feed level | – | electrodeless |

| Maximum lateral travel of large slide ball screw (X) | mm | 800 |

| Maximum longitudinal travel of small slide ball screw (Z) | mm | 600 |

| Two-axis servo motor | – | 15/18 |

| Tool holder fast movement-vertical | mm/min | 2000 |

| Tool holder fast movement-horizontal | mm/min | 2000 |

| Knife table form | Four screw posts | |

| Tool section size | mm | 50×50 |

| Main motor power | kw | 15 |

| Total weight | kg | 5000 |

| Finish turning outer roundness | mm | 0.03 |

| Finish turning outer cylindricality | mm | 0.035/300 |

| Flatness of the end surface | mm | 0.030/300 |

| Surface roughness of fine turning outer circle | Ra3.2 |

Product description

C6016PLC controlled floor lathe can mainly undertake various turning work, and can turn the end face, outer circle, cone and other processes of various parts. The machine tool spindle adopts the national professional structure design, which has good rigidity; the machine tool adopts the bottom chip removal method, which is convenient for chip removal. The machine tool also has a separate oil pump, forced lubrication, as well as fast movement, terminal insurance and other functions. The speed, feed rate and power characteristics are reasonably designed, which can well meet the needs of rough and semi-finishing. This machine tool has no thread processing function, is equipped with a PLC two-axis servo motor, and a common screw structure. It has the characteristics of strong rigidity, high efficiency, energy saving, safety and reliability, easy operation and beautiful appearance compared with mechanical machine tools.

1.Bed

The bed adopts an integral structure, resin sand molding, and the guide rail adopts high-frequency quenching and grinding technology, which makes the machine tool have good wear resistance and precision retention. The Π-type reinforcement ribs make the bed have excellent rigidity, vibration resistance and resistance to cross-sectional distortion. The side tilt rear chip removal method is convenient for chip removal. The bed has undergone advanced finite element mechanics analysis, which theoretically proves the rationality of the structure, excellent rigidity, shock resistance and resistance to cross-sectional distortion.

2.Spindle box

The spindle adopts the spindle four bearing support form, mainly front and rear support, reasonable bearing configuration and span design, equipped with high-precision spindle bearings, so that the machine tool has good rotation accuracy and high spindle rigidity and load-bearing capacity. The optimized transmission system and gears treated by high-frequency quenching and grinding technology make the spindle box have the characteristics of low noise, high transmission accuracy and large output torque.

3.Electrical system

The electrical system mainly realizes strong and weak current control, so that the electromechanical is effectively integrated, and the control and operation of the machine tool can be easily realized. All electrical components are selected from domestic safety certified products. The bed slide adopts PCL control and handheld control unit in the vertical and horizontal directions.