As a metal cutting machine tool, metal band saws are widely used in the machining industry. Whether it is profiles, pipes or solid materials, metal band saws are good at sawing. As the main equipment for sawing materials, the scientific selection and use of band saws are directly related to the efficiency of the entire processing process and the quality of the product.

Problems customers often encounter

A common question is often mentioned in customer consultations for sawing machines: “What is the difference between 4035 and 4235, and what do they mean?”, “I want to cut bundles of pipes, what kind of sawing machine is better?” This is the most common problem.

In the face of many domestic sawing machine manufacturers and unfamiliar foreign brands, it is normal for the purchasing engineer to have such doubts, so how to choose the specifications and models of the sawing machine correctly; how to reasonably determine the number of sawing machines to be purchased according to the number of workpieces to be sawed and the efficiency requirements ; How to obtain the best comprehensive cost performance and how to use the band sawing machine scientifically on the premise of satisfying the efficiency and the quality of workpiece processing, etc., these issues are all the procurement engineers have to consider.

So how to choose?

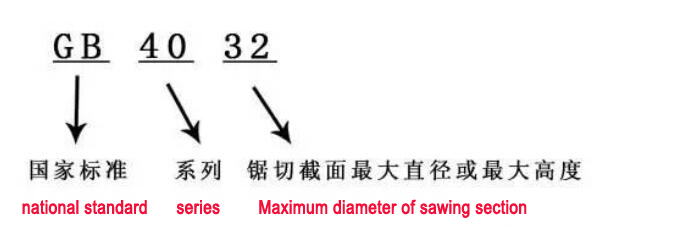

As the main equipment of the cutting process, the band sawing machine is used to cut metal or non-metallic materials accurately and efficiently. Therefore, the selection of the sawing machine should be mainly based on the shape and size of the raw material. The standards issued by the national industry ministry define the sawing machine model accordingly. For example, GB in the GB4032 metal band sawing machine refers to the meaning of the national standard, 40 refers to a series of products, and 32 refers to the maximum diameter or maximum height of the sawing machine.

As shown in the picture:

For the following cutting range, the cutting range will be slightly different according to manufacturers. Taking GB4032 as an example, the cutting range is: Φ320□H320*W400 (Φ indicates circular cross-sectional area, indicates square cross-sectional area). What kind of cutting method should be based on the requirements of the finished material, such as cutting the material into angles.

Example: door frame

If you need to cut both sides of the material into a trapezoid, you must choose an angle saw, which can change the angle during the cutting process (for example: 30°, 45°, 60°)

As shown below: