In the field of machining, lathe is extremely critical equipment. Among them, short thread lathe and universal lathe both play an important role in production, they have both similarities and obvious differences.

Similarities:

1.Structure

Both have a basic bed structure, the bed provides a solid support base for the entire machine tool, to ensure the stability of the machine tool in the process of operation.

Both have a spindle box, used to install the spindle and the related variable speed device, through the adjustment can meet the speed required for different workpiece processing.

They are equipped with tool holders for mounting the tools and for transverse and longitudinal movement to perform cutting operations.

2.Machining principle

Both are based on the combination of rotary movement of the workpiece and linear movement of the tool to achieve cutting operations. In this way, excess material is removed from the workpiece to achieve the desired machined shape and size.

Points of difference:

1.Thread machining mechanism

Short Thread Lathe: A unique approach to thread forming movement, which does not rely on a screw, but is done by means of an end cam mounted in the middle of the bed. When the cam is raised, the tool holder advances for thread turning; when it is lowered, the tool holder returns.

Universal lathe: the main use of the screw and open and close the fit of the nut to achieve the relative movement between the tool and the workpiece in the thread machining.

2.Impact on spindle and screw

Short-thread lathe: its unique end cam design effectively avoids frequent forward and reverse rotations of the spindle and screw during high-speed thread turning, which reduces the wear and tear of mechanical parts and improves the processing efficiency.

Universal lathe: In complex thread machining or frequent change of cutting direction, the spindle and screw often need to rotate forward and backward frequently, which will affect the machining efficiency and component life to a certain extent.

3.Adaptability of workpieces to be processed

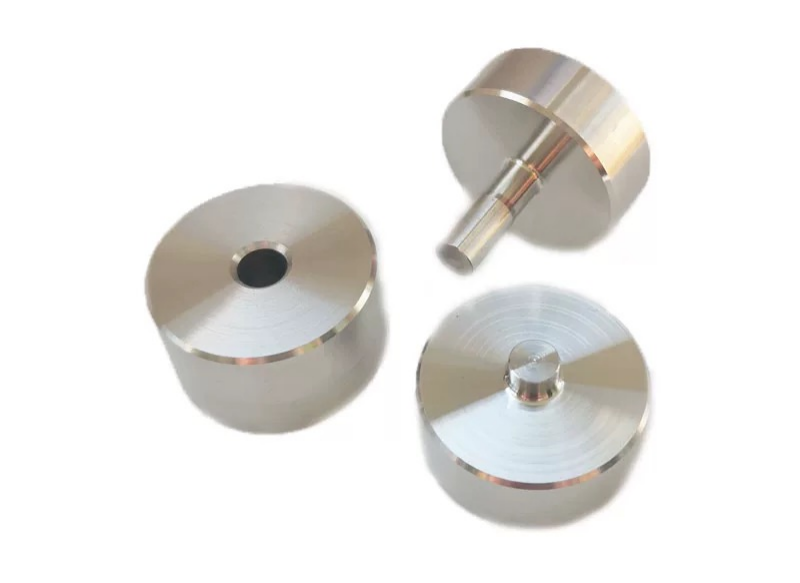

Short thread lathe: as the name suggests, it is optimally designed for short threaded workpieces and is mainly used for turning short threaded workpieces and threads of oil pipes and casing for oil and geological drilling. It has the advantages of high efficiency and high precision in the field of short thread machining.

|

|

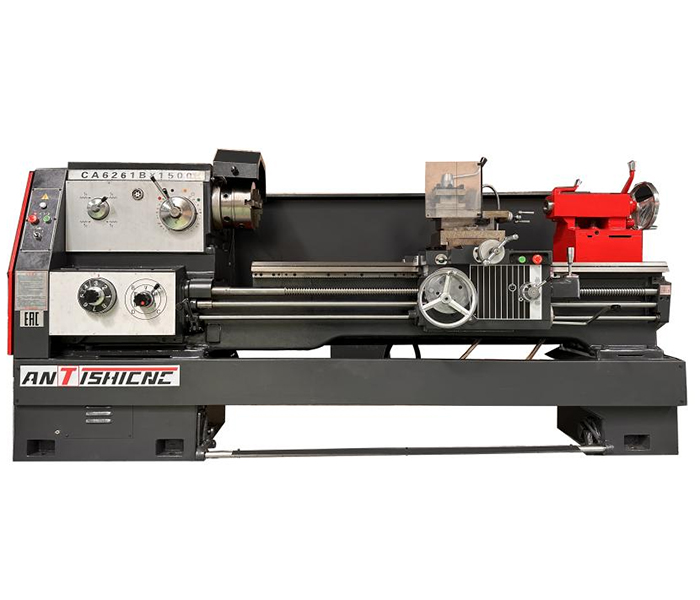

Universal lathe: more versatile, can process many types of workpieces, such as shafts, disc parts, etc. Thread machining is only one of its many functions, and it is not particularly targeted at the length of thread machining.

|

|

|

|

In short, after understanding the similarities and differences between the short thread lathe and ordinary lathe, for machining enterprises to reasonably select equipment, optimise the production process is of great significance, can effectively improve production efficiency and product quality, so that the production of enterprises to maximise the benefits.

Keywords: lathe,universal lathe,threading lathe