In the mold manufacturing industry, precision and efficiency are key indicators for measuring production standards. The turret milling machine has become the core equipment for various mold production processes, thanks to its flexible machining methods and reliable precision control. It plays an irreplaceable role in manufacturing processes ranging from injection molds to die-casting molds, and from rough machining to fine processing of key mold components.

1.Injection mold processing

The processing accuracy of injection molds directly affects the quality of plastic products. Turret milling machines can complete multiple key processes in this field. In cavity and core processing, turret milling machines can accurately shape the molded parts of the mold by milling complex surfaces. For example, in the manufacture of mobile phone shell injection molds, the milling machine controls the tool path through CNC programming to achieve precise milling of the cavity surface, ensuring that the appearance accuracy and dimensional tolerance of the mobile phone shell are within ±0.05mm. For lateral core-pulling mechanism components such as sliders and inclined tops, the turret milling machine can accurately mill grooves and bevels to ensure that the matching clearance between the slider and the guide groove is controlled at 0.02-0.05mm to prevent flash during injection molding. In addition, in the processing of the pouring system, the milling machine can mill out the main channel, branch channel and gate with precise dimensions to optimize the flow path of the plastic melt and improve the efficiency of injection molding.

2.Stamping die processing

The high-precision requirements of stamping dies make the turret milling machine a key processing equipment. In the processing of punching dies, for the edge contour processing of the punch and die, the turret milling machine can first perform rough milling to remove most of the excess, and then use fine milling with wire cutting technology to make the edge clearance reach 0.01-0.05mm (depending on the material thickness) to ensure that the edge of the punch is smooth and burr-free. Taking the stamping die of automotive parts as an example, the milling machine can process the unloading plate hole to ensure that the single-sided matching clearance with the punch is 0.05-0.1mm, ensuring a smooth unloading process. In terms of forming die processing, such as the curved forming part of the automotive cover die, the turret milling machine can achieve smooth transition milling of the radii and bevels of the punch and die through manual or semi-automatic feeding, avoiding material cracking during stamping and improving the forming quality of stamping parts.

3.Die-casting mold processing

The working environment of die-casting molds is harsh, and the quality requirements of molds are extremely high. The turret milling machine plays an important role in its manufacturing process. When processing the mold cavity and pouring system, the turret milling machine uses a high-speed milling process for the die-casting mold cavity of high-temperature resistant alloy materials (such as H13 mold steel) to reduce the surface hardening layer, ensure the mold cavity size accuracy at ±0.05mm, and the surface roughness Ra≤0.8μm to prevent the die-casting from sticking to the mold. At the same time, the milling machine can accurately control the cross-sectional area of the runner and the volume of the overflow groove, optimize the metal liquid filling path, and improve the yield rate of die-casting. In the cooling system processing link, the turret milling machine processes cooling water channel holes with a diameter of φ6-φ10mm through precise drilling and boring, ensuring that the water channel is evenly distributed, effectively controlling the mold temperature, and avoiding defects such as deformation of die-casting parts due to local overheating.

4.Rubber mold processing

The processing of rubber molds is also inseparable from the turret milling machine. In the manufacturing of rubber molds such as tire molds, the milling machine can process the parting surface and cavity of the mold. By milling grooves and bosses, the precise positioning of the mold when closing is guaranteed, so that the flatness of the parting surface is ≤0.03mm, the pattern clarity and size consistency of the rubber products are ensured, and the production needs of rubber products are met.

The core advantage of the turret milling machine in the mold manufacturing industry lies in “flexibility, cost-effectiveness and ease of operation”, which is especially suitable for small and medium-sized batch mold production, multi-variety mold change processing and mold repair scenarios. Although there are limitations in high-precision and automated production, its complementarity with CNC equipment makes it a basic configuration equipment for mold workshops, especially favored by small and medium-sized enterprises.

Recently, Shanghai ANTISHI received an inquiry from a Brazilian customer. They needed a turret milling machine with a worktable size of 254*1370mm and a spindle motor of 5HP for the mold manufacturing industry. Through the customer’s email and other information, we recommended our turret milling machine X6325D to the customer.

Shanghai ANTISHI turret milling machine X6325D

The main parameters of the machine are as follows:

| Technical | X6325D |

| Table size (L×W) | 254×1370(10”x54”) |

| Ram Travel | 470mm |

| X/y/z Travel | 940/400/400 |

| Distance from spindle nose to table surface | 0-400mm |

| Spindle travel | 127mm |

| Spindle motor | 3.75KW/5HP |

| T-slot No.and size | 3*16 |

| Spindle hole taper | ISO40 |

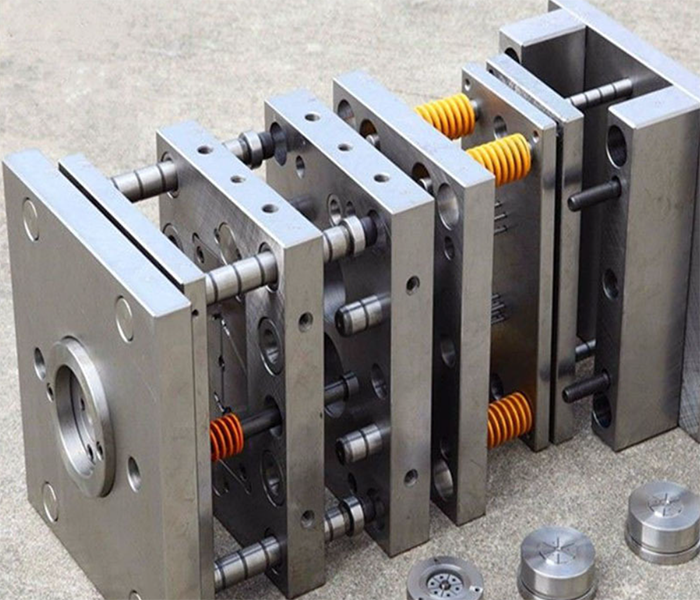

Machinable workpiece display:

Injection mold |

Stamping mold |

Die casting mold |

Extrusion mold |

In the mold manufacturing industry, product precision, production efficiency and cost control are the key elements of corporate competitiveness. With its unique performance, the turret milling machine has shown significant advantages in mold processing and has become an important production equipment for many mold manufacturing companies.

We not only have turret milling machines, universal milling machines, gantry machining centers, boring and milling machines, vertical machining centers, turning and milling centers, but also lathes, sawing machines, grinders, drilling machines, planers and slotting machines. If you have similar needs, please contact Shanghai ANTISHI: contact@antsmachine.com, our technical team will be able to match you with the most suitable technical solution.

Keywords: Turret milling machine, Bed milling machine, Universal milling machine