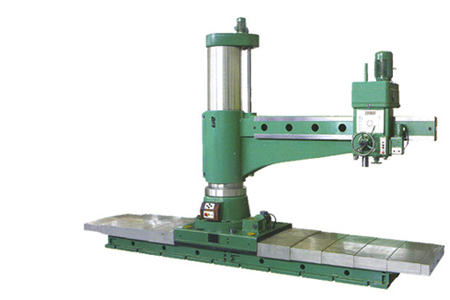

Product Features

● The guide rail, column and box body of the Z33 universal radial drilling machine are made of high-strength cast iron. After the casting, the casting is heat treated to eliminate the internal stress of the casting. The casting that eliminates the internal stress after heat treatment can maintain the stability of the main body of the machine tool, the surface of the column and the guide rail for a long time. Each contact surface is quenched to maintain the hardness of the guide rail and the column, and the machine tool can maintain the accuracy and durability for a long time;

● The electrical and motor of the Z33 radial drilling machine adopt national standard grade. Under the control of national standard grade electrical, the machine tool is more energy-saving and safe to run for longer;

● The rotating gear of the main shaft box is precision ground and carburized and quenched. The gear box runs with low noise and good transmission force;

● Domestic Harbin bearings are selected for each rolling component bearing, and the whole machine tool can perform high-speed cutting;

● The main shaft box adopts the internal circulation lubrication of the automatic oil supply system, and the gears and bearings are fully lubricated, which solves the shortcomings of insufficient lubrication of the top gears of the traditional lubrication method;

● The main shaft is equipped with a travel protection switch, which solves the problem of damage to the main shaft or gear when the main shaft is fed to the top when the worker misuses or automatically feeds;

● Column safety locking device switch, automatic lifting can automatically cut off power when workers forget to loosen the locking device, which can well protect the column from being strained and the turbine and worm from slipping;

● The lead screw is made of a brand manufacturer, which is produced and processed in strict accordance with the tempering, quenching and other lead screw processing techniques. The lead screw produced by the special lead screw processing equipment is precision ground by a grinder, and the service life is twice that of the ordinary lead screw. The nut is a brass nut with good wear resistance and precision;

● The Z33 universal radial drilling machine has undergone strict product quality accuracy screening from rough casting, parts procurement, and supplier selection. Each process has been strictly inspected to ensure the overall accuracy requirements of the machine tool when it leaves the factory.