A drilling machine is a hole processing machine that mainly uses a drill bit to process holes in solid materials. Its working principle is that the motor drives the spindle to rotate, the spindle drives the drill bit to rotate, and the drill bit feeds along the axial direction to drill a hole in the workpiece. For example, in a common desktop drilling machine, the power of the motor is transmitted to the spindle through the pulley, so that the drill bit obtains rotational motion, and then the feed of the drill bit is controlled by the joystick.

1.The structure of the drilling machine:

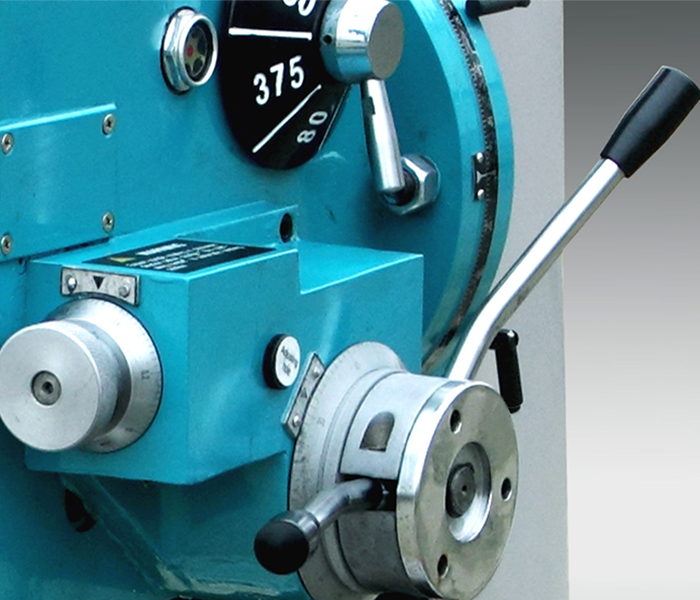

Spindle part: This is the key component of the drilling machine, which connects the drill bit and drives it to rotate. The speed of the spindle is usually adjustable to meet the drilling needs of different materials and hole diameters. For example, on some precision drilling machines, the spindle speed can be accurately adjusted to hundreds of revolutions per minute to tens of thousands of revolutions per minute.

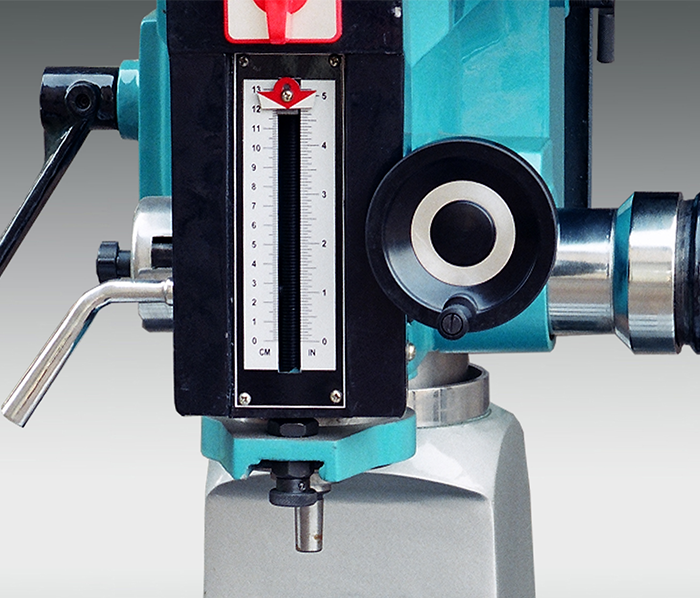

Feed mechanism: used to control the axial feed movement of the drill bit. The feed amount can be adjusted according to the requirements of drilling. For example, the automatic feed drilling machine can steadily push the drill bit downward according to the set feed speed, and the manual feed drilling machine controls the feed speed through a handwheel or handle.

Workbench and fixture: The workbench is a platform for placing workpieces, and its surface usually has T-slots for installing fixtures. The function of the fixture is to fix the workpiece to ensure that the workpiece does not move during the drilling process. Common fixtures include flat-nose pliers, V-blocks, etc. Flat-nose pliers are suitable for clamping square or rectangular workpieces, and V-blocks are used to clamp cylindrical workpieces.

Column and base: The column is used to support the spindle box and the workbench to ensure their relative position is stable. The base provides stable support for the entire drilling machine and generally has a large mass and area to prevent the drilling machine from shaking during operation.

|

|

|

2.Classification of drilling machines

| name | picture | introduce |

|

Bench strong drilling machine |

|

It is small in size and simple in structure, and is usually installed on a workbench. Its drilling diameter is generally small, and it is suitable for processing small parts and thin plate materials, such as drilling holes on electronic equipment housings and small mechanical parts. |

|

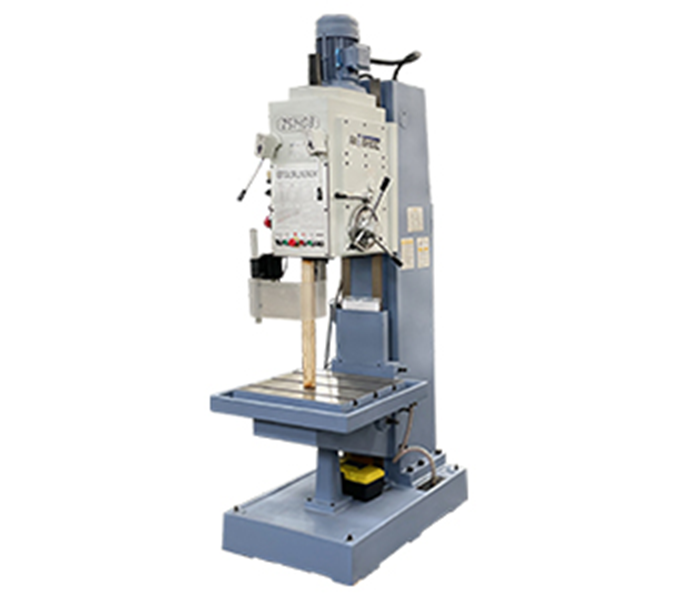

Vertical drilling machine |

|

The spindle is arranged vertically, and its power and processing capacity are stronger than those of a bench drilling machine. It can process larger workpieces and larger diameter holes, and is widely used in machining workshops to manufacture various mechanical parts. |

|

Radial Drilling Machine |

|

It has a rocker arm that can rotate around the column, and the spindle box can move on the rocker arm. This drilling machine is highly flexible and suitable for drilling holes in different positions of large workpieces without frequently moving the workpiece. For example, it is very convenient to drill holes in large molds and heavy mechanical parts. |

3.Application industry of drilling machine

(1)Mechanical manufacturing industry:

Parts processing: When manufacturing various mechanical parts, drilling machines are used to process threaded bottom holes, mounting holes, etc. For example, when manufacturing an engine cylinder block, a drilling machine is needed to drill multiple holes for mounting pistons, valves and other components. These holes have high requirements for accuracy and position accuracy, and the drilling machine can meet the requirements through precise feed control and positioning.

Mold manufacturing: There are usually a large number of cooling holes, ejector holes, etc. on the mold that need to be processed. The drilling machine can drill these holes on hard materials such as mold steel, and the quality of the holes can be guaranteed through suitable drill bits and processing technology, such as surface roughness, cylindricity, etc., which meet the requirements of mold use.

(2)Construction industry:

Metal structure processing: In the manufacturing process of metal structural parts (such as steel beams and steel columns) used in construction, the drilling machine is used to drill connection holes. These holes are used to install bolts, rivets and other connectors to ensure the stability of the metal structure.

Decoration project: In interior decoration, the drilling machine can be used to drill holes in materials such as metal decorations, door and window frames, and to install small parts such as hooks and hinges.

(3)Automobile repair and manufacturing industry:

Automobile manufacturing: In the production process of automobile parts, drilling machines are used to process holes on various parts, such as automobile chassis parts, engine parts, etc.

Automobile repair: In the process of automobile repair, drilling machines can be used to process some special repair tools, or to perform simple drilling repairs on

damaged parts. For example, when the mounting holes of some parts of the car are damaged, the drilling machine can be used to re-drill holes to install new connectors.

4.Case Analysis-Z5150B

Recently, Shanghai ANTS Machine Equipment Co., Ltd. received an Algerian customer. The maximum drilling diameter is: 50mm, the worktable size is: 480×560mm; the main motor power is 3kw.

Next, Shanghai ANTISHICNC engineers will select a suitable vertical drilling machine for the customer. Please check the following simple basic technical parameter table of the Z5150B vertical drilling machine:

| Technical parameters | Z5150B vertical drilling machine |

| Maximum drilling diameter | 50mm |

| Maximum spindle feed resistance | 16000N |

| Maximum spindle torque | 350 N.m |

| Main motor power | 3 kw |

| Spindle speed | 31.5-1400 (12 levels) r.p.m |

| Workbench size | 480×560mm |

For more technical details and knowledge of drilling machines, please contact Shanghai ANTS Machine Equipment Co., Ltd. We provide customers with timely technical support, training and high-quality machine tools.

Keywords: Drilling machine, Drilling machine application, Vertical drilling machine application