When it comes to precision machining, vertical milling machines are the backbone of modern manufacturing. Unlike their horizontal counterparts, these machines offer unique advantages in terms of setup flexibility, tool accessibility, and space efficiency. But with so many variations—from basic CNC milling machines to advanced 5-axis VMCs—how do you know which one is right for your shop?

we’ll break down the different types of vertical mills, their key features, and real-world applications. Whether you’re machining aerospace components, automotive parts, or medical devices, understanding these machines will help you make an informed decision.

What Makes Vertical Milling Machines Different?

At first glance, a vertical milling machine might look similar to a horizontal mill, but the spindle orientation changes everything. The vertical alignment allows for:

Better visibility of the workpiece (no chips piling up on top)

Easier setup for drilling and plunge cuts

More compact footprint, saving valuable shop floor space

But not all vertical mills are created equal. Some are manual, some are CNC-controlled, and others offer multi-axis capabilities. Let’s explore the different types in detail.

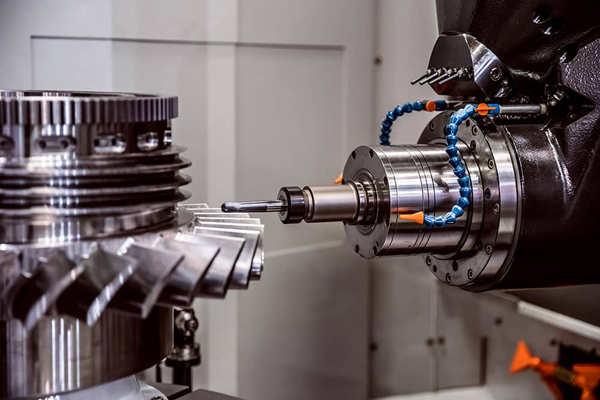

1. CNC Vertical Milling Machines: The Workhorse of Modern Shops

If you’ve ever walked into a machine shop in the last 20 years, chances are you’ve seen a CNC milling machine in action. These computer-controlled beasts have replaced many manual operations because of their:

✔ Precision – No more hand-cranking feeds; CNC ensures repeatability within microns.

✔ Speed – Rapid traverse rates and optimized toolpaths mean faster cycle times.

✔ Automation – With automatic tool changers (ATCs), they can run unattended for hours.

Real-World Use Case:

A job shop in Ohio switched from manual mills to CNC vertical mills and saw a 40% increase in throughput—just by eliminating manual tool changes and reducing setup errors.

2. Vertical Milling Centers (VMCs): Taking Automation Further

A Vertical Milling Center (VMC) is essentially a CNC mill on steroids. It comes with:

Enclosed work area (keeps coolant and chips contained)

Automatic tool changer (ATC) (holds 10-30+ tools for uninterrupted machining)

High-pressure coolant systems (extends tool life in tough materials)

Why Choose a VMC Over a Basic CNC Mill?

If you’re running production batches (even small ones), the VMC’s automation pays for itself quickly. One aerospace supplier in Texas reduced their part handling time by 60% after switching to a VMC with a pallet changer.

3. 3-Axis vs. 4-Axis vs. 5-Axis VMCs: Which One Fits Your Needs?

✔ 3-Axis VMC (X, Y, Z Linear Movement)

Best for: Flat parts, pockets, and simple contours

Limitation: Requires repositioning for multi-sided machining

✔ 4-Axis VMC (Adds a Rotary A or B Axis)

Best for: Cylindrical parts (e.g., camshafts, turbine blades)

Game-Changer: Continuous machining on multiple faces without reclamping

✔ 5-Axis VMC (Simultaneous Multi-Axis Movement)

Best for: Complex geometries (aerospace impellers, medical implants)

ROI Justification: One 5-axis machine can replace multiple setups on a 3-axis mill

Case Study:

A medical device manufacturer in California was struggling with tight-tolerance titanium implants. After investing in a 5-axis VMC, they reduced setup time from 4 hours to just 20 minutes per part.

4. Hardrail vs. Linear Guide VMCs: The Rigidity vs. Speed Debate

Hardrail VMC Machines (Box-Way Construction)

Pros:

Unmatched rigidity for heavy cuts in steel or titanium

Durable in high-vibration environments

Cons:

Slower rapid traverse speeds

Requires more maintenance over time

Who Should Use Them?

If you’re machining hard metals (like Inconel or tool steel), a Hardrail VMC will outlast linear guide machines under heavy loads.

Linear Guide VMC Machines (Linear Motion Bearings)

Pros:

Faster accelerations (ideal for aluminum and plastics)

Smoother surface finishes

Cons:

Less suitable for aggressive roughing

Who Should Use Them?

High-speed machining (HSM) shops that prioritize cycle time reduction.

5. Key Considerations Before Buying a Vertical Milling Machine

Before pulling the trigger, ask yourself:

What materials will I mostly machine?

Hard metals = Hardrail VMC

Aluminum/composites = Linear guide VMC

How complex are my parts?

Simple 2.5D shapes = 3-axis

Multi-sided contours = 5-axis

What’s my production volume?

Low-mix/high-mix = CNC mill with quick-change fixtures

High-volume = VMC with pallet changer

The milling machine you choose today will impact your shop’s productivity for years. While a 3-axis VMC might seem like the safe choice, investing in a 5-axis machine could open doors to higher-margin work.

If you’re unsure, look for a machine builder that offers live demos with your actual parts. Nothing beats seeing how the machine performs on your specific geometry.

Need Help Selecting the Right Vertical Mill?

Contact our machining experts for a free consultation tailored to your shop’s needs.

Keywords:

Vertical Milling Machine

CNC Milling Machine

Vertical Milling Center (VMC)

3-Axis VMC

4-Axis VMC

5-Axis VMC

Hardrail VMC Machine

Linear Guide VMC