Shanghai Antishi radial drilling machine factory instruction manual, its operating handle, handwheel, button uses I-table

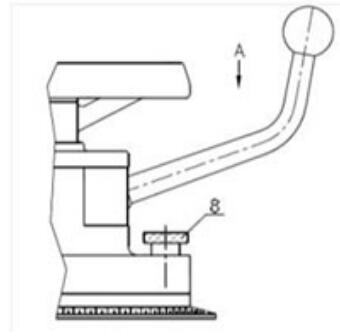

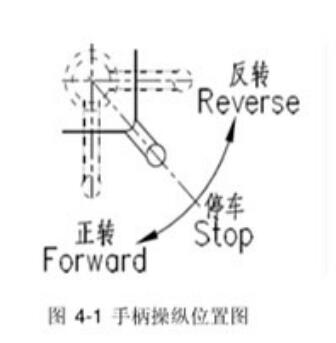

1. Starting of the spindle: To start the spindle, press button 1<SB2 >, and then the indicator light in the button will light up. At this time, turn the handle 15 to the forward or reverse position as shown in Figure 4-1, and the spindle will rotate clockwise or counterclockwise.

2. Transformation of spindle speed and feed rate: Turn the handle 9 to align the rotation speed shown on it with the arrow to get the required rotation speed. Rotate the handle so that the arrow on it is aligned with the required feed amount, and the feed amount can be changed.

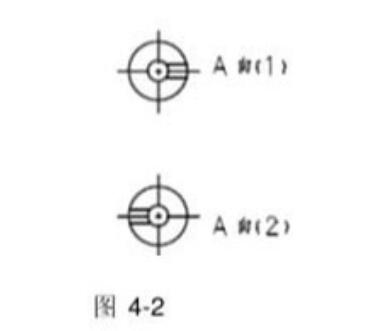

3. Feed of spindle: Motor feed: Press the handle 14 down to the limit position, then pull the handle 10 out, and the motor feed has been turned on. If the spindle is turning downward; If the spindle is reversed, the spindle will feed upwards; To cut off the motorized feed, just lift the handle 14. Manual feed: push the handle 10 inward, and turn the handle 10 clockwise or counterclockwise to drive the spindle to feed up or down. Micro-feeding: Lift the handle 14 up to the horizontal position, then pull out the handle 10, and turn the handwheel 17 to realize micro-feeding. Fixed cutting: Turn the knob 8 in Figure 4-2 to the position shown in direction A (1). At this time, the dial is disengaged, and you can turn the dial to make the required cutting depth equal to the auxiliary ruler on the box body “ 0” Line alignment, and then turn the knob 8 to the position shown in direction A (2) in Figure 4-2. At this time, the dial is engaged and the motorized feed is turned on; When the cutting depth reaches the required value, the handle 14 will automatically lift, cut off the motorized feed, and complete the fixed-distance cutting. Thread tapping: the operation is the same as manual feeding. Note: This operation should be limited to no more than 8 times per minute to prevent the main motor from being damaged by overheating.

4. Clamping and loosening of headstock and column: The clamping and loosening of the column is performed by the handle 4. When the handle is picked up to the top, the upright post is loosened; In the lowest position, the column is clamped. The clamping and loosening of the spindle is performed by the handle 6. When the handle is lifted to the uppermost position, the headstock is loosened: the headstock is clamped at the lowermost position. 5 Clamping, loosening and lifting of rocker arm: The clamping and loosening of the rocker arm is performed by the operation of the handle 5. When the handle is turned to the right, the rocker arm is clamped, and when the handle is turned to the right, the rocker arm is loosened. Note: Due to the electric interlocking control, the rocker arm lifting movement is allowed only after the rocker arm is released. When the button 12 is pressed, the rocker arm rises; when the button 13 is pressed, the rocker arm falls. When the rocker arm rises or falls to the required position, release the button and the lifting movement will stop. 6. Problems that should be paid attention to when the rocker arm rotates: Because Shenyang Zhongjie radial drilling machine factory does not have a confluence ring device, it is important to pay attention to the fact that it cannot always rotate continuously in one direction when pushing the radial arm to rotate.

Want to know more about the process of the product? ANTISHI has a mature team of engineers who are very familiar with heat treatment processing and can handle product processing problems including packaging technical problems. In addition, during the installation and design process, our engineer team can be assigned to solve problems on the spot, to the greatest extent possible. Helping producers to carry out convenient and efficient production has always been the goal of our company. Customers can visit the official website http://www.antsmachine.com, or send questions to our email: sales.shanghai@antsmachine.com consult