The working principle of the gear grinding machine is divided into two categories: the molding method and the spreading method.

1.Forming method

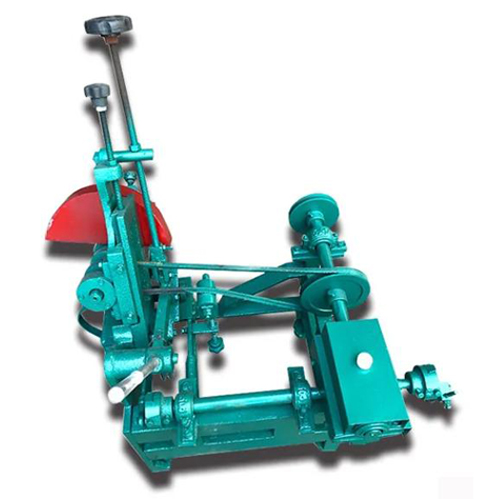

According to the molding method of processing the molding wheel grinding machine grinding wheel by molding wheel dresser in the axial profile to repair the tooth shape, the grinding wheel frame can be used in the vertical direction of the feed. The gear to be ground is supported by the indexing frame and tailstock, and the table is used for longitudinal reciprocating motion to grind out the tooth surface, and indexing is carried out after each tooth is ground. In the machine tool for grinding helical gears, the grinding wheel can be turned at an angle according to the helix angle of the workpiece, and the workpiece can be rotated additionally at the same time of reciprocating motion. If the grinding wheel holder of the machine can make the grinding wheel enter into the workpiece of the internal gear, it can grind the internal gear. Forming wheel grinding machine has a simple structure, high efficiency, and accuracy up to grade 5, suitable for batch production, especially suitable for gears with fewer teeth (e.g. less than 10).

|

|

2.Spreading Method

According to the spread into the method of grinding machine according to the shape of the grinding wheel can be divided into 4 kinds.

① Disc-shaped grinding wheel grinding machine: the narrow side of two rotating disc-shaped grinding wheels is equivalent to the two tooth surfaces of the rack, the workpiece through the rolling disk and steel belt for the spreading motion, the table along the workpiece axial reciprocating motion in order to grind out the entire width of the tooth. After each tooth is ground, the teeth are divided by the indexing headstock through the indexing disk. This type of machine can also be used to grind oblique teeth with an additional device. If a grinding wheel is inserted into the internal gear, the internal gear can be ground. This kind of machine tool generally horizontal layout, and a vertical layout is used when the processing diameter is larger than 1 meter, and the precision can be up to grade 4, which is suitable for grinding high-precision gears.

|

|

② Conical grinding wheel gear grinding machine: The axial profile of the grinding wheel is trimmed to a tooth shape of the rack and reciprocates in a straight line along the tooth direction. Workpiece through the worm wheel, screw, and exchange gear to complete the development and indexing movement, but also with a rolling disk and steel belt for the development of movement, the use of worm gear or indexing disk for indexing movement. The grinding wheel holder can grind helical gears when it turns through an angle according to the spiral angle of the workpiece. This kind of machine tool is easy to adjust, has good versatility, suitable for single-piece batch production, widely used.

|

|

③ Worm wheel grinding machine: the principle is similar to that of the hobbing machine, the grinding wheel is in the shape of a large-diameter single-ended worm, the workpiece turns over a tooth for every revolution of the grinding wheel, and the transmission ratio is accurate, some of them are driven by mechanical transmission, some are driven by synchronous motors, and some are driven by grating and servo motors. The workpiece is fed along the axial direction during grinding to grind the whole tooth surface. The grinding wheel is turned by a diamond turning tool or rolled into a worm shape by a rolling wheel. The machine has a vertical layout, continuous indexing, high grinding efficiency, suitable for batch production of medium modulus gears, especially for gears with a large number of teeth, and precision up to level 4.

|

|

④ Large plane grinding wheel gear grinding machine: the working plane of the grinding wheel is equivalent to a tooth surface of the rack, with involute samples (also used in steel belts and rolling discs) to produce the spreading motion. The grinding wheel and workpiece are not for workpiece axial reciprocating motion, grinding one side of the tooth face after the use of indexing plate tooth, in turn, grinding all the tooth face. Then the workpiece is turned around and the other side of the tooth face is ground. The machine has a horizontal layout, simple structure, stable performance, and accuracy up to grade 3, mainly used for grinding gear shaper, shaving cutter, and measuring gears for metrology.

|

|

The gear grinding machines produced by Shanghai ANTS Machine Equipment Co., Ltd. have high efficiency, high precision, high quality, long service life, and exquisite appearance, and are well received by customers.

Shanghai ANTS Machine Equipment Co., Ltd. provide a variety of gear grinding machines, can support customized services, if necessary, you can consult our technical staff.