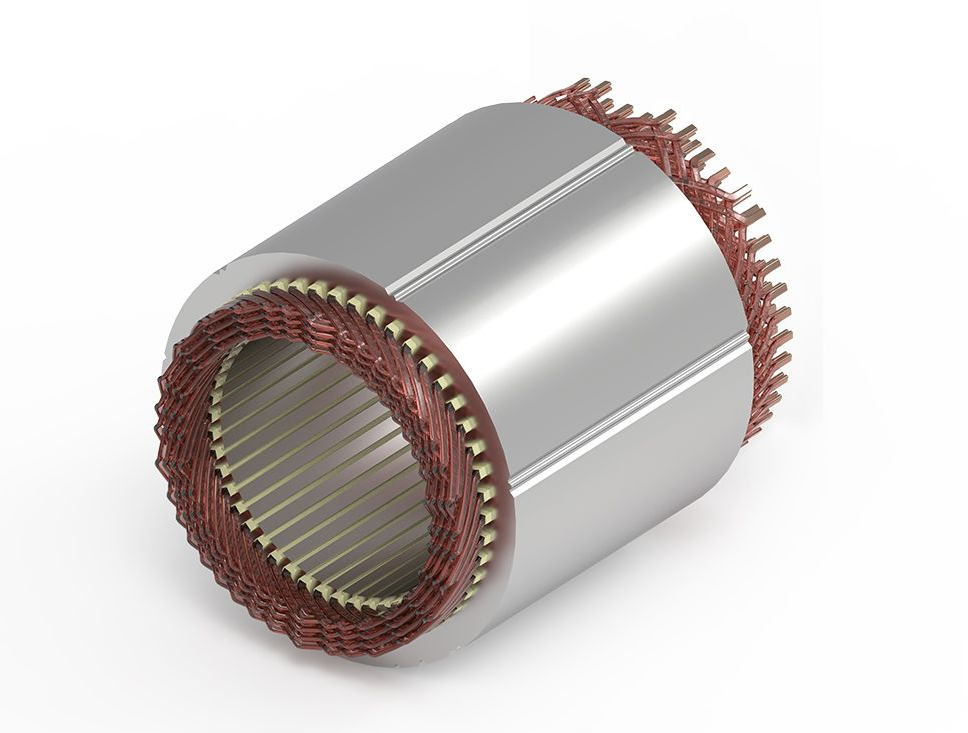

Motor stator is an important part of the motor, it corresponds to the rotor, in the motor, the stator and rotor work together to realize the conversion between electrical energy and mechanical energy. The manufacturing process of the motor stator directly affects the performance and service life of the motor, so the machine used to produce the motor stator is particularly important, the press-assembly hydraulic press machine is the preferred equipment for the production of motor stator.

So, what are the advantages of making motor stator with press-assembly hydraulic press machine?

1. Improve the level of manufacturing process

Through the precise positioning of the positioning device, the consistency of the press-assembly stator assembly and the shell is guaranteed, which improves the level of the manufacturing process and enhances the qualification rate in the manufacturing process.

2. Improvement of production efficiency

As the opening of the working area is facing upwards, the stator, the casing and the pressed combination of the two can easily enter and exit the working area, and it also eliminates the need to turn the pressed combination into a flat process, which improves the production efficiency.

3. Improved product quality

Through precise control of the press-assembly force and position, servo four-column hydraulic press machine can ensure that the stator, rotor, terminal precision press-assembly, reduce deformation and damage phenomenon, improve the overall performance and service life of the motor.

4. Reduce production cost

By precisely controlling the press-assembly process and reducing the scrap rate, the servo hydraulic press machine can reduce the production cost of the motor.

5. High operation safety

Stator and casing in the lifting process, there is no perspective blind zone, the operator operation safety, and in the press-assembly process, basically do not need to turn over the stator or casing, reducing the potential safety hazards.

These advantages make the press-assembly hydraulic press machine play an important role in the production of motor stator, which not only improves the production efficiency and product quality, but also reduces the production cost and enhances the market competitiveness of the enterprise.

Shanghai ANTISHICNC is a professional manufacturer of hydraulic press machine. Motor stator press-assembly hydraulic press machine have various structural forms, Shanghai ANTISHICNC can customize four-column, single-arm, gantry, horizontal and other structures according to the characteristics of the motor stator/rotor process of the special hydraulic press equipment. Shanghai ANTISHICNC production of motor stator press-assembly hydraulic press machine with movable worktable, the worktable under the hydraulic cylinder push and pull, with easy loading and unloading operation, accurate positioning, pressure loading smooth, reliable characteristics, by the customer’s praise. For example, the following 100 tons of three-beam four-column hydraulic press.

100 tons motor stator press-assembly hydraulic press machine features:

1.100 tons of motor stator press-assembly hydraulic press machine adopts four-column hydraulic structure, good rigidity, high precision, compact structure, cost-effective and economical.

2. Hydraulic control using cartridge valve integrated system, small impact action is reliable, long service life, less leakage points.

3.100 tons of three-beam four-pillar hydraulic press machine cylinder sealing elements, reliable, long life.

4. Tensioning, crimping slider can be linked into one to realize the single-action process action.

5. Guide rail automatic lubrication device and electromechanical integration safety devices, such as: cylinder lower chamber support circuit, cylinder upper and lower chamber interlock circuit, etc., superior safety.

6.100 tons three-beam four-column hydraulic press machine can realize two kinds of molding process: fixed pressure and fixed stroke, with the function of holding pressure and delaying time, and the delaying time is adjustable.

7. The working pressure and stroke can be adjusted within the specified range according to the process requirements, easy to operate.

| Description | YQ32-100T |

| Slider stroke (mm) | 500 |

| System pressure (Mpa) | 25 |

| Nominal pressure (KN) | 1000 |

| Maximum headroom (mm) | 600 |

| Effective area of working table (mm) | 1400*1400 |

Remark: The above parameters are for reference only, the actual parameters of the machine please refer to the technical program of Shanghai ANTISHICNC.

If you have motor stators forming processing needs too, welcome to consult Shanghai ANTS Machine Equipment co., ltd. We have rich experience in manufacturing and using hydraulic press machine and can provide you with professional technical support.