CNC spline shaft milling machine is mainly used for hobbing splines and gears. It is a machine tool for processing spline shafts. Spline shafts are important components in mechanical transmission. There are multiple keyways on its shaft. These keyways are evenly distributed on the circumference of the shaft and can transmit torque when combined with the spline sleeve. CNC spline shaft milling machine controls the movement of the tool through the CNC system, and can accurately process the shape of the spline on the surface of shaft parts.

Mainly used in the following fields:

1.Automobile manufacturing

2.Mechanical equipment manufacturing

3.Aerospace industry

4.Shipbuilding industry

Recently, Shanghai ANTISHICNC received an inquiry from a tractor manufacturer in Turkey. They needed a CNC spline shaft milling machine to process their tractor transmissions and the spline shafts in the drive shafts of their cars. Based on the customer’s parameter information and product drawings, we recommended our YK6212 CNC spline shaft milling machine to the customer.

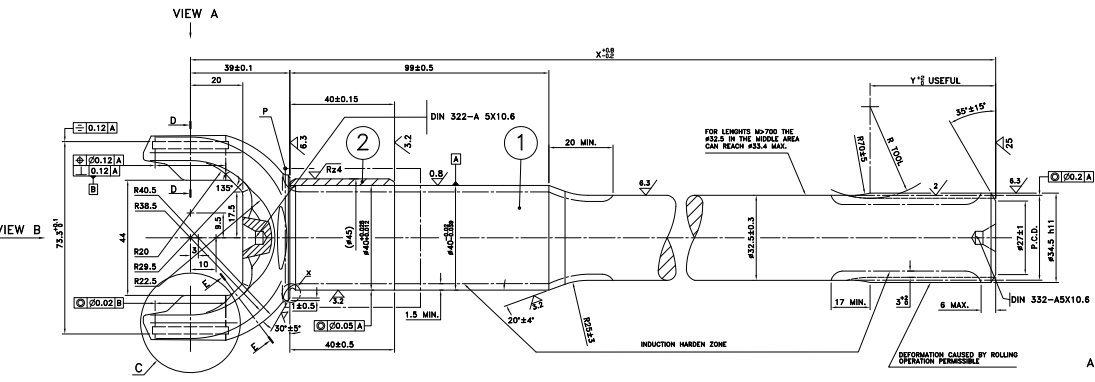

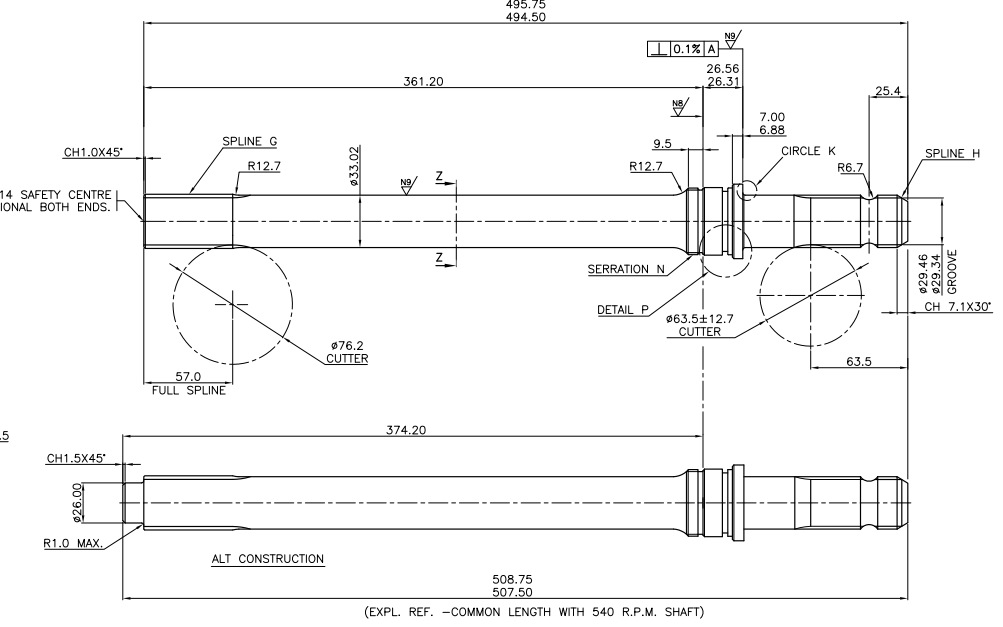

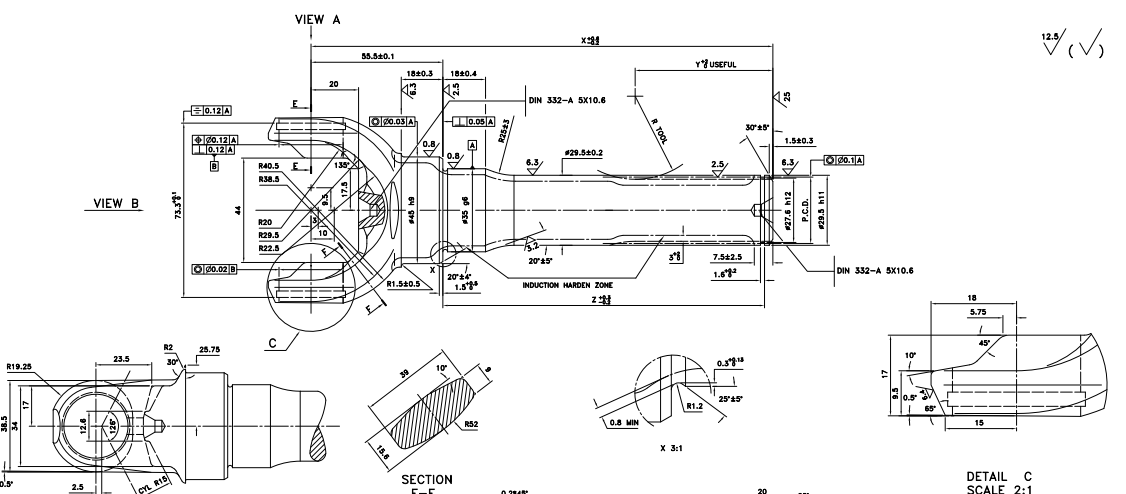

Part of the customer’s drawing information:

|

|

|

YK6212 CNC spline shaft milling machine is suitable for automobile, tractor, gear processing and other related machinery manufacturing industries. It is a high-efficiency machine tool for batch production of spline and gear parts. It is suitable for high-speed/high-efficiency dry cutting of workpieces under air cooling conditions, and is equipped with a cooling oil circuit for wet cutting. It can be selected and used according to the needs of the tool and production process.

| Specifications | YK6212

CNC spline shaft milling Machine |

| Max. diameter of workpiece to be machined | φ125mm |

| Max. length of workpiece to be machined | 900 mm |

| Max. module to be machined | 3mm |

| No. of teeth to be machined | 6-100 |

| Max. length of workpiece | 1000mm |

| Center height of machine | 195mm |

| Distance between center of cutter and that of workpiece | 40-150mm |

| Max. size of hob to be mounted | φ130 × 115mm |

| Dia. Of the hob arbor | φ22、φ27、φ32mm |

| Range of the cutter rotation speed (stepless) | 60~600 r/min |

| Adjustment Angle of milling head | ±40° |

| Max.amount of hob shift | 100 mm |

| Amount of hob shift | 0.18 mm/r |

| Max.protrudent distance from the tailstock center | 40mm |

This machine can perfectly meet the processing needs of customers, hobbing spur spline shafts, spur/helical cylindrical gears and other workpieces. It can also hob coupling gears and splines, and can process step gears and drum gears. This machine has a wide range of hob speed: steplessly adjustable from 60-600 rpm, which can double the cutting efficiency. The machine tool adopts the 5-axis GSK CNC system to achieve three-axis linkage of the machine tool.

If you have similar needs, please contact Shanghai ANTISHICNC: contact@antsmachine.com. We not only have CNC spline shaft milling machines, High Efficiency Precision Generating Gear Grinding Machine,Profile Gear Grinding Machine, but also High Efficiency Gear Hobbing Machine,High Efficiency Gear Skiving Machine. ANTISHICNC technical team will definitely be able to match you with the most suitable technical solution for you.

Keywords: Spline shaft, Gear, Gear processing, Gear hobbing machine, CNC milling machine