Refrigeration copper pipes usually serve as refrigerant transmission channels. The refrigerant circulates continuously in the refrigeration cycle, and the copper pipes are responsible for connecting various parts and transmitting the refrigerant to each part to complete the refrigeration task. Refrigeration copper tubes can also be used as manufacturing materials for evaporators and condensers. They are widely used and play an irreplaceable role. So, how does a tube bending machine make refrigeration copper tubes? The following is introduced to you by Shanghai ANTISHICNC engineers:

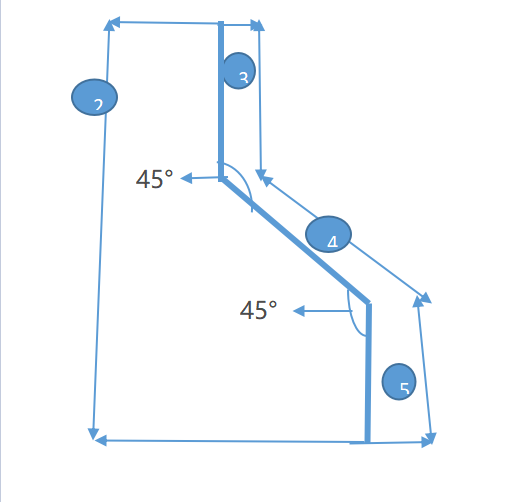

As shown in the picture, there are two parts of the refrigeration joint that need to be bent at 45 degrees, so we can choose to use “one tube, one mold” or “one tube, two molds (same diameter)” for one-time processing.

For the choice of pipe bending machines, there are two types: semi-automatic pipe bending machines and fully automatic pipe bending machines. When using semi-automatic pipe bending machines, engineers need to pay attention to the bending radius of the copper pipe at any time and should not be less than 1.5 times the diameter of the pipe. Since the pipe has a certain degree of elasticity, when the external force exerted during bending is removed, the pipe will spring back to an angle, and a certain amount of bending must be allowed during bending. The amount of springback is related to the mechanical properties, wall thickness and bending radius of the pipe material. Generally, the springback angle is about 2° to 4° when bending copper pipes. This very tests the engineer’s skillful use and accuracy of the pipe bending machine. control.

Use a CNC pipe bending machine, you can greatly improve production efficiency and ensure product quality. By easily adjusting process parameters, the CNC pipe bending machine can accurately and stably complete straightening, rounding, feeding, bending and other actions, ensuring the bending accuracy of pipe parts.

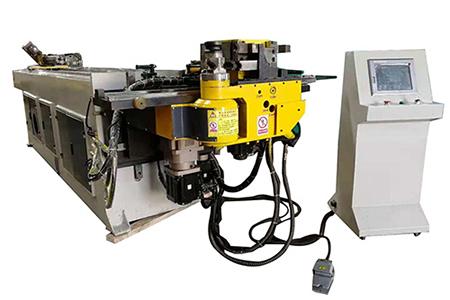

However, the quality of bent copper tubes is more sensitive to process parameters, so sufficient preliminary preparation and trial production work are required, especially for bent thin-walled copper tubes. If the process parameters are improperly selected, wrinkles will easily occur, leading to scrapped parts. How to obtain these process parameters efficiently and accurately to fully ensure the quality of bent pipe products is a hot research topic in CNC pipe bending machines. The main differences between semi-automatic and fully automatic pipe bending machines can be seen in the figure:

| Name | Picture | Difference | Advantage |

| Semi-automatic pipe bending machine

(NC type) |

|

Semi-automatic pipe bending machine is a hydraulic integrated equipment. The operator sets the bend himself and needs to reset the positioning after bending once. | 1. Suitable for single bending parts 2. Suitable for processing small quantities |

| Fully automatic pipe bending machine

(CNC type) |

|

The fully automatic pipe bending machine is a CNC processing equipment. All processing methods are programmed. The CNC pipe bending machine automatically locates the position between the bent pipes, including the rotation of the pipes (B axis) and the distance between the bent pipes (Y axis). And ensure that the machine uses brackets to hold the tube before making the first bend and automatically moves to the next position | 1. Suitable for multiple curved parts, with high processing accuracy, and can process various difficult pipes Suitable for processing large quantities |

Shanghai ANTISHICNC can provide timely technical support, training and spare parts supply. We only produce high quality pipe bending machines!

Tags : Pipe Bender,Semi-automatic pipe bending machine,Fully automatic pipe bending machine,CNC pipe bending machine