A hydraulic press machine is a machine that utilizes hydraulic fluid to generate compression force. It consists mainly of a frame, base, power system and control system driven by a hydraulic cylinder and operated according to Pascal’s Law. Hydraulic presses are commonly used in processes such as forging, riveting, molding, undercutting, deep drawing and metal forming.

Ⅰ.How are hydraulic pressmachine categorized?

1.According to the use of points

① Manual hydraulic press machine: generally small hydraulic press, used for pressing, pressing and other processes.

② Forging hydraulic press machine: for free forging, ingot billet and non-ferrous and ferrous metal forging.

③ Stamping hydraulic press machine: used for a variety of plate stamping, like a variety of metal sheet stamping molding, including drop, punching, stretching, bending, turning over, precision blanking.

④ Calibration press hydraulic press machine: for parts calibration and assembly.

⑤ Laminated hydraulic press machine: used for pressing of plywood, particle board, fiberboard and insulating material boards, etc. It has a large stroke, a large number of layers, and a large distance between the layers, and the number of boards that can be pressed is large.

⑥ Extrusion hydraulic press machine: used for extruding all kinds of non-ferrous and ferrous metal wires, tubes, bars and profiles.

⑦ Press hydraulic press machine: for powder metallurgy and plastic products such as pressing molding, like powder products hydraulic press, isostatic pressure hydraulic press, magnetic materials hydraulic press, abrasive products hydraulic press, diamond hydraulic press.

⑧ Packing, briquetting hydraulic press machine: for metal chips and other pressure into blocks and packing.

2.According to the action mode points

① Pp-pressure hydraulic press machine: this type of hydraulic press working cylinder installed in the upper part of the body, easy to operate, easy to realize the rapid downstream, the most widely used.

② Downward pressure hydraulic press machine: this type of hydraulic press working cylinder installed in the lower part of the body, the center of gravity is low, good stability, products can avoid oil leakage pollution.

③ Double-action hydraulic press machine: the upper movable beam is divided into internal and external slider, driven by different hydraulic cylinders, the pressure is the sum of internal and external slider pressure. Flexible working mode, suitable for deep drawing and forming of sheet metal, widely used in the automobile manufacturing industry.

④ Special hydraulic press machine: such as angle hydraulic press, horizontal hydraulic press machine.

3.According to the structure of the body points

① Column hydraulic press machine: hydraulic press on the beam and the lower beam (table) connection using columns, four columns, double columns, single columns and other combinations of forms, the pressure of the hydraulic press is more for the four-column structure, the machine stability is good, the lighting is also better.

② Overall frame hydraulic press machine: the body is made of casting or section steel welded, generally hollow box structure, good bending performance, the column part of a rectangular cross-section, easy to install plane adjustable guides, movable beam movement with high precision, in the plastic products and powder metallurgy, sheet metal stamping hydraulic presses in a wide range of applications.

③ Mortise and tenon type structure hydraulic press machine: due to the mortise and tenon type frame all four sides are connected with the work surface, so you can give the machine to set up a double moving table without affecting the operation of the machine’s field of vision, its structure is the most compact, the layout is beautiful, has a high degree of rigidity, anti-deviation loading capacity, the size of the frame is not subject to the overall volume of the assembled limitations, especially for large-scale racks, mainly used in hydraulic molding.

4.According to the transmission form

① Pump direct drive hydraulic press machine: each hydraulic press is equipped with a separate high-pressure pump, small and medium-sized hydraulic presses for this form of transmission.

② Pump accumulator drive hydraulic press machine: high-pressure liquid using a centralized supply approach, can save money, improve the utilization of hydraulic equipment, but the need for high-pressure accumulator and a centralized pressure supply system to balance the low load and peak load on the need for high-pressure liquid in the use of multiple hydraulic presses (especially more than one large and medium-sized hydraulic presses) in the case of more feasible.

Others are in accordance with the working medium (water pressure, oil pressure), the mode of operation (manual, semi-automatic, fully automatic) and tonnage (100T, 500T, etc.) to be classified.

Ⅱ.How to choose the right hydraulic press according to the parameters of the hydraulic press machine?

Parameters are the basic technical data of the hydraulic press machine, which are determined according to the use of the press and the type of structure, which reflects the working capacity and characteristics of the hydraulic press machine, and also basically determines the contour dimensions and the total mass of the body of the hydraulic press. Therefore, the following parameters should be confirmed before matching a suitable hydraulic press machine:

1.Nominal pressure (nominal tonnage)

Nominal pressure refers to the maximum force that can be generated on the name of the hydraulic press machine, numerically equal to the working fluid pressure and the product of the total working area of the working plunger, which reflects the main working capacity of the hydraulic press machine.

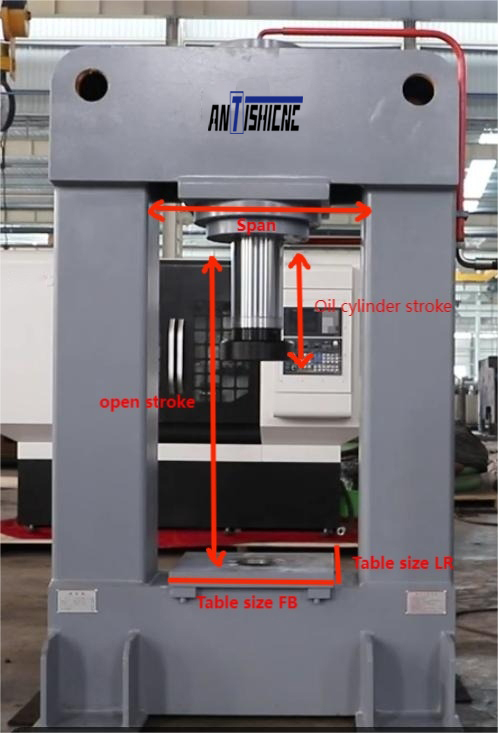

2.Maximum headroom (opening height) H

Maximum headroom H is the distance from the upper surface of the table to the lower surface of the movable beam when the movable beam stops at the upper limit position.

3.Maximum Stroke S

Maximum stroke S refers to the maximum distance that the movable beam can move.

4.Table size (LXW)

The table size refers to the effective size that can be utilized on the table surface.

5.Whether the bottom ejector cylinderis required

The bottom ejector cylinder can be used to facilitate the release of the product from the mold.

6.Gantry hydraulic press machine, single arm hydraulic press machine, or four column hydraulic press machine

| Gantry hydraulic press machine | Single arm hydraulic press machine | Four column hydraulic press machine |

|

|

|

Shanghai ANTS Machine Equipment Co., Ltd. provide a variety of hydraulic press machines, support customized services. If necessary, please feel free to consult our technical staff.