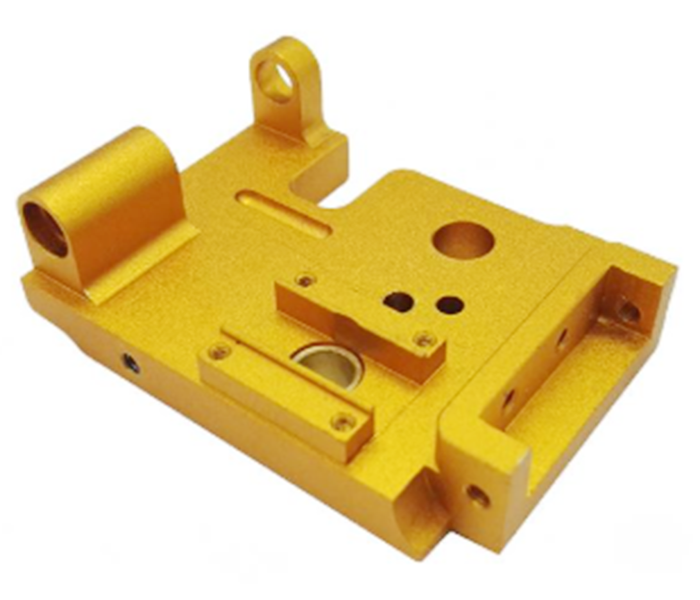

Product name: Solenoid valve seat

Material: A6061

Processing technology: milling machine processing, CNC processing

Dimensions: 60*40*30mm

Processing accuracy: 0.02mm

|

|

Recently, a customer consulted Shanghai ANTISHICNC Company on how to process a solenoid valve seat on a vertical machine center. The following are the technical solutions matched by engineers and the processing steps shared:

1.Vertical machinecenter Clamping and positioning

For valve seats of different sizes, adaptive adjustments can be made by adjusting the screw and the abutment bump.

Use the bottom surface of the valve seat or the processed reference surface as the positioning reference, and use the T-slot of the machining center workbench or a special fixture for precise positioning.

The fourth axis is needed for the solenoid valve seat processing of this customer

2.Vertical machinecenterdrilling processing

Use high-speed steel or carbide drill bits, and adjust the speed and feed rate according to the valve seat material (such as 145 steel, 445 steel)

For high-precision holes (such as ±0.01mm), roughing and finishing are required. Leave a 0.1-0.2mm margin after roughing, and use a reamer or boring tool for finishing.

Multi-axis linkage processing: Use the X/Y/Z axis linkage function of the vertical machining center to complete the drilling of each hole position in sequence according to the drawing coordinates (such as the simultaneous processing of the double drill head in Abstract 1).

3.Vertical machining center machine tapping processing

Use rigid tapping or flexible tapping tool holders, and select the corresponding tap according to the thread specifications (such as M6-M12).

The machining center needs to be equipped with the spindle synchronous tapping function to ensure that the pitch and feed match (refer to the integrated processing equipment in Abstract 7).

For batch processing of solenoid valve seats, Shanghai ANTISHICNC Company recommends VMC430 CNC milling machine. The model reference is as follows:

| Specifications | VMC430 |

| X axis Travel | 500 mm |

| Y axis Travel | 320 mm |

| Z axis Travel | 410 mm |

| Spindle end face to table | 70-480 mm |

| Spindle center to column guide | 360 mm |

|

|

If you are also interested in solenoid valve seat milling,welcome to consult!

Keywords: Milling machine, CNC milling machine, Vertical machine center, Solenoid valve milling