Machine tool guide soft belt is a kind of nano-polymer composite material based on PTFE. It is a high-end guide soft belt product for all kinds of precision machine tools, CNC equipment and machining centers with high precision requirements. It is rich in solid lubricant particles and has excellent friction and wear characteristics.

Due to the use of nanometer ultra-fine formula, the material of the soft guide rail is uniform and dense, and has strong wear resistance, which is widely used in the manufacture and Maintenance, especially suitable for all kinds of precision machine tools, CNC machine tools and machining centers with high precision requirements.

The guide rail soft tape can generally be pasted on the short guide rail (moving guide rail or upper guide rail) of the sliding guide rail pair, so that it can slide with the long guide rail (static guide rail or lower guide rail). For example, the lathe can be pasted on the slide rail, the tailstock rail and the sliding surface of the wedge, while the planer should be pasted on the bed rail.

Special properties:

High wear resistance: The wear resistance is 10 times that of cast iron guide rails, and the guide rail accuracy is well maintained;

Low friction: the friction coefficient is less than 0.04, which is only 1/3 of the cast iron guide rail, which greatly reduces the driving energy consumption;

No crawling: The dynamic and static friction coefficients are close, the micro-feed positioning is good, and the operation is stable;

Good shock absorption: can reduce noise and vibration, improve processing accuracy;

Good lubrication: good self-lubricating performance, even if the lubrication system fails, the guide rail can be avoided from scratches;

Easy maintenance: Because the hardness of the soft belt is much lower than that of the metal, the wear is mainly on the soft belt. The maintenance only needs to replace the new soft belt, and it also completely avoids the concave of the bed guide rail.

Soft tape pasting process of CNC machine tool guide rail

Guide rail soft tape pasting process (suitable for machine tool maintenance, the use of the product can refer to the implementation)

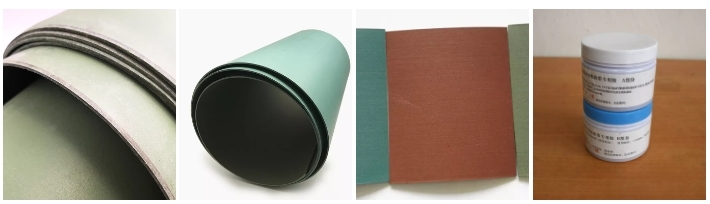

Preparation: The bonding site should be clean and dust-free, the ambient temperature should be 10-40℃, and the relative humidity should be less than 75%. The soft tape is treated with sodium naphthalene on one side, the dark brown side is the bonding surface, and the blue-green side is the working surface. The remaining soft tape and special glue should be kept in moisture-proof and light-proof storage. In order to improve the bonding strength, the surface roughness of the bonding surface of the metal guide rail should be Ra12.5~25μm (the finish is 3~4); the matching guide rail should be slightly wider than the soft belt guide rail, and the surface roughness should be Ra0.8~1.6μm (Finish 7 to 8).

Cutting: The cutting size of the soft tape can be appropriately placed according to the actual size of the bonding surface of the metal guide rail. The width can be placed on one side of 2 to 4 mm to prevent slippage during pasting; the length can be placed on one side of 20 to 60 mm, which is convenient for pasting. Tighten both ends.

Cleaning: Before bonding, it is necessary to remove rust and oil on the bonding surface of the metal guide rail. You can use emery cloth, sandpaper or wire brush to remove rust impurities, then scrub with acetone and dry; if the old machine tool is seriously oily, you can use NaOH first. Scrub with lye, and then scrub with acetone; if conditions permit, sandblast the bonding surface of the metal guide rail. At the same time, scrub the dark brown adhesive surface of the soft tape with acetone and dry it for later use.

Glue dispensing: The special glue must be used with the preparation. Weigh and mix according to the weight ratio of A component/B component = 1/1. After stirring evenly, the glue can be applied (see the bottle sticker instructions for details).

Glue: Use “tooth scraper” or 1mm thick bakelite sheet for glue. The special glue can be applied longitudinally on the metal guide rail and laterally on the soft belt. The coating should be uniform. The glue layer should not be too thin or too thick. The amount of glue used can generally be controlled at about 700g/m² Control between 0.08 ~ 0.12mm.

Paste: When the soft tape is just pasted on the metal guide rail, it needs to creep back and forth and left and right to make it fully contact; squeeze from the center of the length of the soft tape to both sides with hands or tools to drive away air bubbles; for large and medium-sized machine tools, BOPP can be used to seal the box With adhesive positioning.

Curing: Curing is carried out at room temperature, curing time: 24 hours, curing pressure: 0.06 ~ 0.1MPa, the pressure must be uniform, and the weight of the machine tool table itself can be used to reverse the pressure on the bed guide rail, and add heavy objects if necessary. The products can be used in batches, and the weight can also be customized as a pressure fitting. In order to prevent the excess glue from sticking to the bed guide rail, a layer of oil sealing paper or a layer of oil can be applied on the bed guide rail surface in advance.

Processing: After curing, the worktable should be pushed along the direction of the guide rail first, and then lifted and turned over to remove the excess glue, and cut the process allowance of the soft tape along the direction of the bonding surface of the metal guide rail and chamfer it. The soft belt has good scraping performance, and can be ground, milled or manually scraped to the required accuracy. During machining, it must be fully cooled by flood coolant, and the amount of feed should be small; with scraping, it can be carried out according to the usual scraping and grinding process. The surface is evenly up to 70%. The way of opening the oil hole and oil groove of the soft belt is the same as that of the metal guide rail. However, it is recommended that the oil groove should not open the soft belt. The depth of the oil groove can be 1/2 to 2/3 of the thickness of the soft belt.