CNC machining centers are divided into hard rail and line rail. When customers buy machining centers, they will ask: Is the hard rail good or the line rail good?What is the difference between the two of them? Shanghai Ants machine Company will give you a detailed introduction in a table:

| Difference | Line rail | Box way rail |

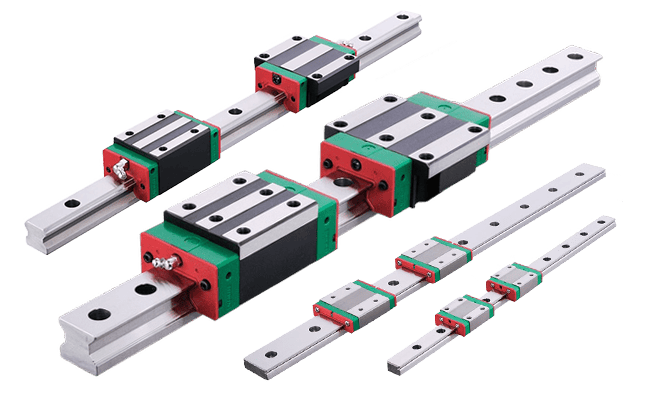

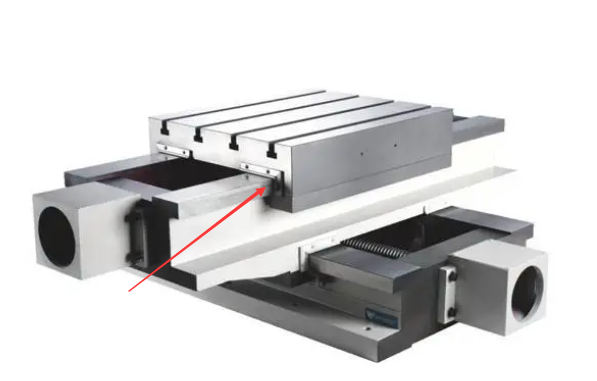

| Picture |  |

|

| Structure | The full name of a linear rail is a linear guide rail, which generally refers to a rolling guide rail.There are two common structures, ball guide rail and roller guide rail. The difference is that the ball guide rail is a point contact type and the roller guide rail is a linear contact type. The principle is one-to-one, and it is also rolled on the guide rail to drive the slide. The linear guide rail withstands relatively little cutting force.We usually call such components “linear guides”. | Box way type rail refers to a cast piece where the guide rail and the bed are integrated, and then the guide rail is processed on the basis of the casting, which is a kind of hard rail.That is, the shape of the guide rail is cast on the bed, and then processed into the guide rail after quenching and grinding. There are also rails that are not necessarily integrated with the bed body and the guide rail. For example, the inlaid steel guide rail is nailed to the bed after processing. The hard rail used in CNC machining centers is generally a rectangular structure, commonly known as a rectangular guide rail.After the guide rail part of the hard rail machining center is quenched with high frequency or ultra-audio, the hardness is generally above HRC50°, which makes it have superior wear resistance (inlaid steel guide rail is also a kind of hard rail), its material number is generally not lower than HT250, and the Brinell hardness of the body is between HB180-HB240.

|

| Advantages | 1.Linear rail machining centers use rolling friction, with relatively small frictional resistance, no crawling phenomenon, and fast running speed, so they are mostly used in high-speed machining and fast tool-moving workpiece machining. 2.Because of its small friction coefficient, it moves faster. 3.Also because the friction coefficient is small, the wear is small. 4.Generally, linear guide rails are made of better materials and more precise equipment, so their accuracy is also higher. 5.Most of the linear rails used in CNC machining centers are roller-type linear rails. |

1.The sliding contact surface of the hard rail is large, which makes the machine tool rigid and stable. 2. Box way type rail machining centers use sliding friction to cause a larger contact surface, and the shock absorption performance is relatively strong. This can better provide processing efficiency and ensure high accuracy. Hard rail machining centers with high rigidity and strength are more suitable for heavy-duty cutting. |

| Disadvantages | 1.The accuracy of linear rail machining centers will decrease after a long period of use, especially when the load is large, so it is especially important for linear rail machining centers to do a good job of lubrication. 2.Because the contact surface is small, its rigidity is lower than that of the hard rail. |

1.When machining workpieces in Box way type-rail machining centers, due to the use of sliding friction on the track, it will bring a lot of friction, so when machining workpieces, a larger cutting force is required, which will cause the vibration amplitude and noise of the machine tool to be greater. 2.Due to the large contact surface, the friction resistance is also large, the wear is faster, the movement speed is limited, and it is easy to produce defects such as crawling. Therefore, most machining center manufacturers use the guide rail laminating process to reduce the wear and crawling defects of the hard rail. |

| Application | It is suitable for high-speed machines, can be cut at high speed, and is suitable for processing products and small precision molds.Nowadays, more precision machining centers use wire rails. | High strength, suitable for heavy Milling, large molds, high hardness workpieces, and workpieces with general accuracy requirements. |

| Summary | when choosing a machining center, you must choose the product that suits you according to your own needs and conditions, so that the processing effect can reach the ideal state. | |

Shanghai ANTISHICNC company provided a variety of CNC machining centers,such as vertical machining centers VMC650, 850, 1060, etc., horizontal machining centers HMC type, gantry machining centers GMC CNC milling machines, etc., which are widely welcomed by domestic and oversea customers.

Tags: Line rail milling machine center, Box way type milling machines,vertical machine center,VMC,CNC milling machine.