In the current era of booming manufacturing industry, the drilling and tapping center, as a cutting-edge processing equipment, is relying on its unique technical advantages to set off a revolution of high-efficiency and precision processing in numerous industries, effectively propelling the manufacturing industry to move forward continuously.

1.Principle of the Drilling and Tapping Center

The drilling and tapping center operates based on the Computer Numerical Control (CNC) system. It precisely controls the rotation of the spindle of the machine tool and the movements of the X, Y, and Z axes to achieve processing operations such as drilling and tapping on workpieces. Operators write programs according to processing requirements. After inputting the control system, the machine tool drives the spindle to rotate the cutting tool at a high speed according to the program instructions, and enables the cutting tool to process the workpiece along the predetermined trajectory under the coordinated action of each axis, ensuring high-precision and high-efficiency processing.

2.Applications of the Drilling and Tapping Center

The drilling and tapping center plays a crucial role in many industries:

3C Industry: It is widely used in the manufacturing of products such as mobile phones, tablets, and laptops. It processes components such as casings, middle frames, and keys, realizing high-precision hole positions and complex shape processing to meet the design requirements of products for being thin, light, and high-performance.

Automobile Parts Manufacturing: It is used for processing components such as engine blocks and transmission housings, manufacturing various oil holes, threaded holes, and conducting small plane and contour milling to ensure the high precision and reliability of the parts.

Medical Device Processing: It is used to produce surgical instruments, medical equipment brackets, and casings. With its high-precision processing capabilities, it ensures the accuracy of the cutting edges of instruments, the quality of threads, and the stability of equipment parts.

Aerospace Field: It is used to process small connectors of aero-engines and precision parts of spacecraft, ensuring the reliability and high performance of parts under extreme environments.

Mold Manufacturing: It is used to manufacture small cores and inserts in injection molds and die-casting molds. Through fine processing, it ensures the precision and surface quality of molds.

3.Advantages of the Drilling and Tapping Center over Other Processing Equipment

Compared with traditional processing equipment, the drilling and tapping center has significant advantages. These include greatly improved processing precision and efficiency. The automated processing and precise control technologies reduce human errors and shorten the processing cycle. It is highly automated and intelligent, capable of automatically completing operations and equipped with various intelligent functions, reducing labor intensity and improving stability and reliability. It has a wide adaptability to materials and can process various non-ferrous and ferrous metals. Its processing capabilities are flexible. With the instruction system and the selection of cutting tools, it can integrate multiple processes and help with the innovative design of products. With the development of the manufacturing industry, its application prospects are broad, which will promote the manufacturing industry to move towards higher precision, efficiency, and intelligence and continuously provide impetus for the development of the industry.

4.Differences between the Drilling and Tapping Center and the Vertical Machining Center

| Projects | Drilling and tapping center | VMC |

| Structure and volume | Flexible mechanical operation, small axial weight, small stroke, small size, such as common about 2 meters * 2 meters * 2.6 meters | Huge structure, such as the 850 model is generally about 2.8 * 2.8 * 3 meters. |

| Tool changer system | Most of the sun type tool magazine, capacity is usually 16 or not more than 21 servo tool magazine | Most of the tool arm type tool magazine, general capacity of 24, can be optional |

| Machining Objects | Mainly processing small aluminum parts and other small metals, small size, such as cell phone frame, etc. | Mainly used for mold processing, mainly steel, can process complex parts. |

| Cutting force | Do not have large cutting power, but can meet the aluminum alloy processing, can also process stainless steel. | Specialized in large cutting, capable of coping with hard metal cutting with large eating capacity. |

| Machining accuracy and speed | High drilling and tapping precision, obvious speed advantage, high spindle speed, fast tool change, high efficiency of batch processing. | Excellent precision, low error for complex surfaces, overall machining speed depends on process and part complexity. |

| Field of application | Suitable for 3C, automotive parts, small molds, medical equipment and other industries small parts processing | Widely used in aerospace, automobile manufacturing, electronic devices, mold processing and other high-precision fields. |

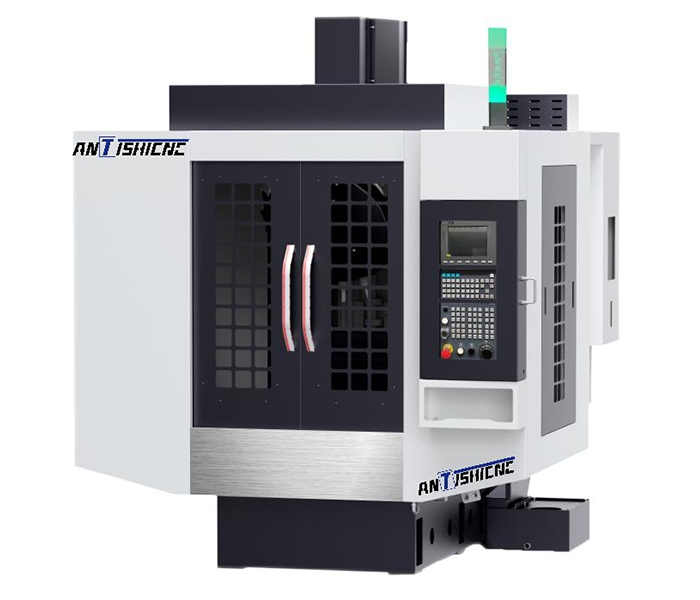

5.Next, we would like to introduce our HW-600 Drilling and Tapping Center

The parameters of HW-600 Drilling and Tapping Center are as follows:

| Specifications | Units | HW-600 |

| Worktable area | mm | 700*420 |

| X, Y, Z travel | mm | 600*400*330 |

| Maximum table load | Kg | 300 |

| The distance from the nose of the spindle to the table | mm | 150-480(optional 200-530/300-630) |

| The distance from the center of the spindle to the end face of the column | mm | 464 |

| Table T-slot | mm | 14T*3*125 |

| Spindle taper/diameter | BT30-Short nose(Ф100) | |

| Spindle speed | rmp | 18000 |

| (X/Y/Z) rapid shift | m/min | 48 |

| Ball screws | mm | XY:28*16 Z:32*16/12 |

| Linear Guides (Linear Rail Width/Number of Sliders) | mm | XYZ:30*2(XY: ball, Z: roller) |

| Weight | Kg | About 3200 |

| Machine size (L*W*H) | mm | 1700*2300*2380 |

Whether it is in the rapid production of 3C products or the high-precision processing of automobile parts, the HW-600 drilling and tapping center can demonstrate excellent performance and provide you with efficient and reliable solutions for your production. With the continuous development of the manufacturing industry, the technology of the drilling and tapping center will continue to innovate and inject new vitality into the development of various industries. We believe that our HW-600 drilling and tapping center will become an ideal choice for you to improve production efficiency and product quality.

If you need a drilling and tapping center, welcome to consult Shanghai ANTISHICNC. We have rich experience in the manufacturing and application of drilling and tapping centers and can provide you with professional technical support.

Keywords: Drilling and Tapping Centers for Metal Connectors, Drilling and Tapping Centers for Industrial Robot Joint Connectors, Drilling and Tapping Centers for Inserts of Injection Molds