The application of grinding machine is very common, in modern industrial production, many parts and components on the size accuracy, shape accuracy and surface roughness requirements are extremely high. For example, the engine blades in the aerospace field have a harsh working environment and need to withstand high temperatures, high pressures and high-speed rotation and other working conditions. The surface accuracy of the blade will directly affect the performance and reliability of the engine. The composite grinding machine is able to complete the grinding process of multiple surfaces in one clamping, effectively reducing the positioning error caused by multiple clamping.

Recently, the Shanghai ANTISHI team received an enquiry from a manufacturer of metal bearings. The customer required a CNC internal grinding machine with a face grinding unit for the main dimensions of 25mm-35mm, 100mm hole depth and 35mm-70mm face. The main dimensions for internal grinding are 25mm-35mm, hole depth 100mm, and endface 35mm-70mm. according to the customer’s needs, we recommended the CG-45 compound grinding machine to the customer.

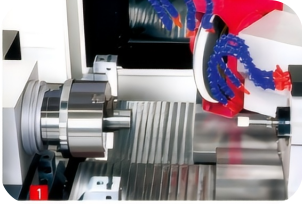

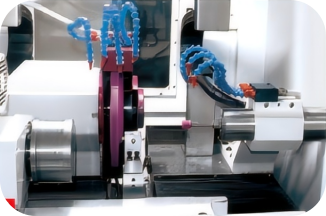

CG-45 is a high-precision composite grinder, mainly used for multi-industry workpieces such as external/internal/endface grinding in one clamping.

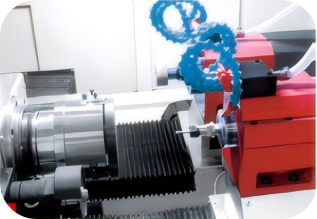

It is a compound grinder that can grind internal circle, internal taper, external circle, external taper and endface in one clamping. It is equipped with Siemens CNC system as standard, and there are many optional accessories to choose from, including automatic rotary device for workhead, automatic OD measuring device, automatic endface measuring device, magnet paper tape filtering device, oil mist collector and so on.

The grinding wheel heads of the machine can be combined modularly

The combinations are available:

|

|

| 1. Inclined feed cylindrical grinding wheel + internal bore grinding wheel | 2. Double cylindrical grinding wheels |

|

|

| 3. Double bore grinding wheel | 4. Inclined feed cylindrical grinding wheels + bore grinding wheels |

It can also be customised with 3 spindles or 4 spindles according to customer’s processing needs, and the internal spindle and external spindle can be combined according to the actual processing situation.

Comprehensive Features

Complex solutions for high-precision grinding suitable for machining small and medium-sized workpieces.

Machine tool industry, automotive engineering, tool and mould industry, aerospace industry, pneumatics/hydraulics, electronics/electrical engineering, medical technology, watch industry and order production industry.

The modular design allows the choice of different grinding wheel spindle combinations to fully meet all requirements for machining. The control system interface makes the operating and programming system very simple and user-friendly to learn. The programming software programs workpiece grinding and grinding wheel dressing directly on the machine control system or on an external PC.

It can be fitted with an automatic feeding and rewinding system to meet the demands of industrialised mass production.

The following are the main parameters of the customised trip of the device:

| ITEM | UNIT | Machine model:CG45 | |

| Processing capability | Maximum grinding diameter | mm | Φ400 |

| Grinding outer diameter length | mm | 200 | |

| Outer wheel size | mm | Φ405*32-60*127 | |

| Grinding inner diameter range | mm | Φ6-200 | |

| Depth of grinding inner diameter | mm | 200 | |

| Maximum length of work piece | mm | 260 | |

| Spindle speed of inner hole grinding wheel | rpm | 20000/40000

(Electric Spindle) |

|

| Wheel dressing | mm | Automatic | |

| CNC system | Set | SIEMENS | |

| Height of grinding wheel spindle center to ground | mm | 1150 | |

| Work Head | Spindle speed | rpm | 0-1000 |

| X axis fastest feed speed | mm/min | 10000 | |

| X axis minimum feed unit | mm | 0.001 | |

| Working head rotation angle | Deg | +15~-5(manual) | |

| Workbench | Z axis fast moving speed | mm/min | 18000 |

| Z axis minimum feed | mm | 0.001 | |

| Maximum travel stroke | mm | 250 | |

| Motor | External wheel spindle motor | KW | 3.75 |

| Internal spindle motor | KW | 3.0 | |

| X axis feed motor (servo) | KW | 1.5 | |

| Z axis feed motor (servo) | KW | 1.5 | |

| Headstock spindle motor | KW | 1.2 | |

| Cooling water pump motor | KW | 0.37 | |

| Lubricating oil motor | KW | 0.25*2 | |

| Others | Coolant tank capacity | L | 200 |

| Machine weight | Kg | 6500 | |

| Equipment size (length * width * height) | mm | 2300*2200*2000 | |

According to the customer’s drawing, his workpiece is enough to use two spindles for internal + external grinding plus rotary table, one spindle for internal grinding and one spindle for endface grinding.

However, the customer’s requirements for the internal hole are very high, we recommended 3 spindles to the customer, one external spindle to grind the end face, one internal rough grinding spindle + one internal fine grinding spindle to grind the internal circle. At present, the suggestion has been adopted by the customer.

If you have metal grinding needs, you can contact Shanghai Anticus team, Shanghai Anticus has many years of experience in the field of metal cutting, there will be a dedicated person to discuss with you.

You can visit our official website www.antsmachine.com

Or email to contact@antsmachine.com

Keywords: Grinding machine, Compound grinding machine, Internal grinding machine