Follower grinder is a kind of high-efficiency and high-precision grinder, which is suitable for grinding various kinds of shafts, disks and other parts. Recently, Shanghai ANTS team received an inquiry from a customer in Malaysia, who is mainly engaged in the production of automobile parts and home appliances.

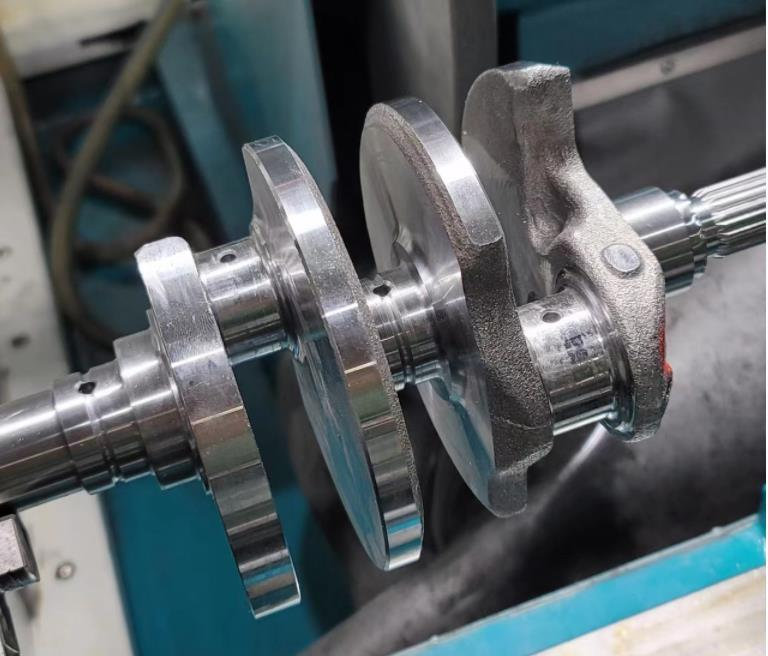

The customer needs to process crankshaft, crankshaft is an indispensable part of the automobile components, is the composition of the power source, the movement of the crankshaft will provide sufficient power for the engine, and also maintain the engine movement of an important part, because the crankshaft work is to do vertical rotation movement, in the rotary movement will inevitably produce collision or friction and other parts, if the roughness of the crankshaft is higher than the standard range, may cause certain damage to the power system of the car, and may also cause some damage to the crankshaft. If the roughness of the crankshaft is higher than the standard range, it may cause certain damage to the power system of the automobile, and the roughness of the crankshaft journal surface should be less than or equal to 0.2μm.

| No | Item | Surface roughness μm |

| 1 | Spindle and connecting rod journals | Ra ≤0.2 |

| 2 | Journal rounding angle | Ra ≤0.4 |

| 3 | Thrust tab end face | Ra ≤0.3 |

| 4 | Oil seal journals | Ra ≤0.4 |

| 5 | Other journal | Ra ≤0.6 |

| 6 | Main journal and connecting rod journal lubricant orifices | Ra ≤0.6 |

Steel and ductile iron crankshaft journal diameter size change maximum limit should not exceed 3% of the nominal size of the new product; journal local pit depth should not exceed 3% of the size of the journal, the area does not exceed 20% of the area of the journal

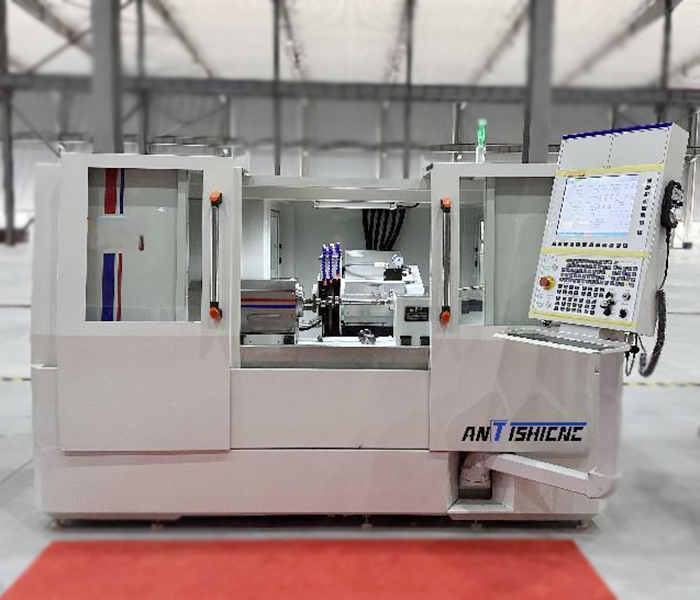

Customers require grinding diameter within 320mm, through the customer’s workpiece diagram and related information we recommend the GP32, and according to the customer’s drawing requirements and customers sent over the unprocessed samples sampling, as shown below, we measured the samples, fully meet the needs of the customer, the customer is very satisfied with our machines.

| Customer processing samples | |

|

|

| ITEM | Technical Parameter |

| Height of Center | 200mm |

| Maximum rotating diameter | Φ380mm |

| Maximum grinding diameter | Φ320mm |

| Grinding length between two tops | 600mm |

| Rotary Table( Model 600) | ﹢6°/-9° |

| Maximum pedestal between two tops | 60kg |

| Grinding carriage | |

| Rotable Angle range (manual) | ±15° |

| Grinding wheel spindle type | Dynamic and static pressure grinding wheel spindle (standard with oil cooling) |

| Wheel spindle speed range | 1650/1850/2100rpm |

| Standard grinding wheel size (φ×W×B) | Φ450×38-50×127mm |

| Special grinding wheel size (φ×W×B) | Φ510×50-80×203mm |

| Wheel spindle motor power | 3.75KW/5.5KW(special) |

| Maximum linear speed of grinding wheel | 45m/s |

| Grinding wheel spindle cooling method | Oil cooling |

| Work piece direct drive head stock | |

| Speed range step less speed regulation | 0-600rpm |

| Taper of spindle taper | MT-4 |

| Tooling adapter set model | MT-4 |

| Work piece head rotation angle range | ﹢15°/-15° |

| Maximum clamping load (with tooling) | 150Nm |

| Permanent magnet synchronous motor power(S1-100%/KW) | 3KW |

| Continuous rated output torque(S1-100%/A) | 47.8Nm |

| Encoder brand | Renishaw |

| Spindle cooling method | Water cooling |

| Repeated positioning accuracy of head stock rotation | ±2arcsec |

| Taper hole runout at shaft end | ≤0.001 |

| Spindle end face beating | ≤0.002 |

| Axial rigidity(N/um) | ≥500 |

| Radial rigidity(N/um) | ≥400 |

| Head stock movement method | Manual standard air floatation |

| Tail stock | |

| Sleeve diameter | Φ50mm |

| Sleeve stroke | 32mm |

| Morse taper | MT-4 |

| Tailstock movement method | Manual standard air floatation |

| Wheel carriage feed-X axis (linear motor) | |

| X axis maximum stroke | 350mm |

| X axis linear motor maximum thrust | 1044-4271N |

| X axis linear motor acceleration | ≤0.2G |

| X axis maximum feed rate | 15m/min |

| HPG (electronic handwheel) minimum feed | 0.0001mm |

| Programmable minimum feed | 0.0001mm |

| Minimum resolution of HEIDENHAIN incremental encoders | 0.0001mm |

| X axis feed positioning accuracy | ≤0.0016mm |

| X axis feed repeat positioning accuracy | ≤0.0014mm |

| Z axis for table feed (servo motor) | |

| Z axis stroke (600 type) | 600mm |

| Z axis servo motor power | 2.2KW |

| Z axis maximum feed rate | 12m/min |

| HPG electronic hand wheel minimum increment | 0.0001mm |

| Programmable minimum feed | 0.0001mm |

| Min. resolution of HEIDENHAIN incremental grating ruler (optional) | 0.0005mm |

| Accuracy of concentricity and parallelism | Whthin 0.005mm |

| Control System | |

| CNC system | Lynuc CNC |

| software | Graphical interactive interface |

| Display screen | 10.4 inch TFT color display |

| keyboard | full keyboard |

| RAM | 3Gb (1Gb users) |

| Number of control axes | Can control up to 7 axes |

| interface | USB/Ethernet/RS232 |

| Machine Tool Electric | |

| Standard 3-phase power supply | 380V 3ph 20Hz |

| Control circuit voltage | 110vAC/24vDC. |

| Input voltage deviation range | ﹢/-10% |

| Full load power consumption (host) | 36KVA |

| Pneumatic supply | |

| Enter air pressure | 5.5bar |

| Request flow | 40-50l/min |

| Air source standard | BS ISO 8573-1:2001 |

| Environmental parameters | |

| Standard machine noise | <75dB(A) |

| Ambient temperature | 0-40℃ |

| Environment humidity | ≤75% |

| Other | |

| Floor space size | 3800×2120mm×2000 |

| Height | 2170mm |

| Net weight | 5440kg |

Shanghai ANTS is a company focusing on machine tool grinding machine for more than 20 years, with high quality and high service quality enterprise pursuit, if your company also has automotive crankshaft processing needs, you can contact us at any time, in addition to crankshaft follower grinding machine, we also have a variety of other grinding machines, such as medical guidewire centerless grinder, surface grinder, cylindrical grinder, tool grinder, etc., you can refer to our website.antsmachine.com