1.Introduction to laser cutting machine:

At present, almost everyone has a desktop computer, which is used for office work and games. For desktop computers, the case is an indispensable part of the computer components. Its main function is to place and fix the various case components, and play a supporting and protective role. The case has the important role of electromagnetic shielding. Its function is to fix and protect the various components of the computer. The computer case is processed by a laser cutting machine, which is strong and beautiful.

As we all know, the fiber laser cutting machine is particularly suitable for cutting and hollowing processing. It has good flexibility, fast cutting speed, high quality, no cutting force, no deformation during processing, and strong material adaptability. For the increasingly sought-after batch and diversified fast processing box market, laser cutting machines have become a winning “weapon”.

The box body generally includes a box body, a bracket, various switches, a panel, an indicator light, etc. The shell is composed of a combination of steel plate and plastic, with high hardness, and mainly plays the role of protecting the internal components of the shell; the bracket is mainly used to fix the motherboard, power supply and various drive devices. The laser cutting machine is very convenient for the increasingly sought-after small batch, multi-variety, fast processing box market with its high flexibility, fast cutting speed, good quality, no cutting force, no deformation during processing, good material adaptability, and can be quickly cut and formed regardless of the simple or complex shape.

2.The advantages of laser cutting machine processing:

Laser processing does not require mold opening, and does not require mold making for different designs, saving a lot of production costs:

Laser processing has high flexibility and unrestricted graphics. Whether it is a simple shape or a complex shape, it can be cut and formed by laser at one time, realizing automatic cutting and nesting, and improving material utilization.

Laser processing has fast cutting speed, high precision, smooth cutting edges, and no burrs, which reduces product unqualified phenomena and shortens the production cycle of products.

The laser cutting machine does not produce any chemical substances that are harmful to the human body and the environment, and meets national environmental protection standards.

On the surface, the computer case seems simple, but the demand is great. The changes in the case structure also reflect the current computer hardware upgrades, system upgrades, and accessories upgrades, from the earliest fully enclosed to the expansion type, to functionality, and finally with heat dissipation as the theme, with a cool appearance, but no matter how the appearance of the computer case changes, the fiber laser cutting machine will adapt to the development of the times, and the high-quality and high-speed cutting characteristics will remain unchanged.

3.Case Analysis — AT-6020/2000W plate laser cutting machine processes ventilation holes in 5-10mm thick carbon steel or stainless steel plates

Recently, Shanghai ANTS Machine Equipment Co., Ltd. received a South African terminal customer who runs a machinery assembly plant. Its main business is processing the ventilation holes of computer cases. The customer’s workpieces are mainly carbon steel and stainless steel. The maximum processing thickness required is 5-8mm, and the processing power required is about 2000W.

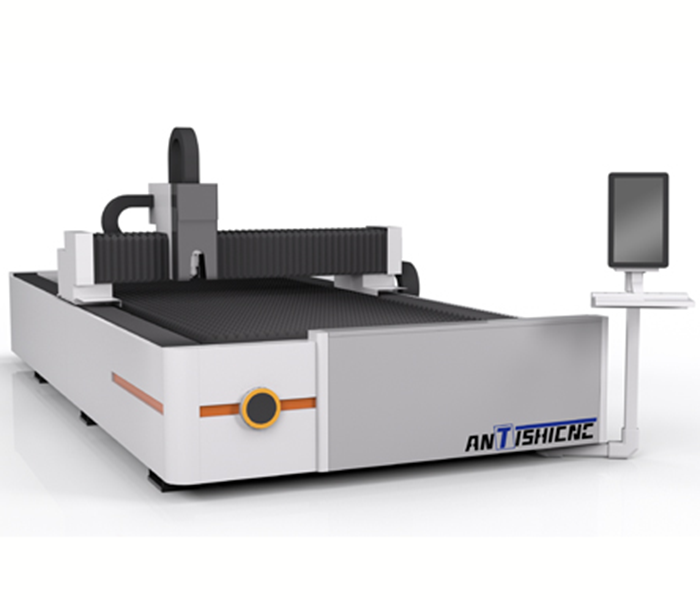

According to customer needs, ANTISHICNC engineers successfully matched a plate laser cutting machine for the customer-AT-6020-2000W.

The maximum worktable diameter is 6000*2000mm. The maximum carbon steel cutting thickness is 10mm, and the maximum stainless steel cutting thickness is 8mm. The following are the basic parameters of AT-6020 2000W:

| Model | AT-6020 2000w |

| Working Area (sheet ) | 6000mmx2000mm |

| Laser Wavelength | 1080nm |

| Laser Power | 2000W |

| Working Life of Fiber Source | More than 100000 hours |

| Laser Beam quality | <0.373mrad |

| Laser Cutting Head | Raytools Automatic Focus Laser |

| Position Type | Red Dot Pointer |

| Cutting Thickness | 0.5-8mm for Large Quantity Process |

For more technical details and laser cutting machine knowledge, please contact Shanghai ANTS Machine Equipment Co., Ltd. We provide customers with timely technical support, training and high-quality laser cutting machines.