Laser cutting:

In the field of automobile manufacturing, laser cutting technology occupies a pivotal position, and its application range is extremely wide, covering almost all key parts such as automobile parts, body structure, door frame, trunk, roof and power battery tray. With its significant advantages of high precision, high efficiency and non-contact processing, laser cutting technology can easily cope with the processing needs of various complex shaped parts.

Laser welding:

Laser welding technology has also been widely used in automobile manufacturing, especially in the production stage of body in white (BIW). Laser welding and laser brazing are currently the two most important welding processes. In addition, laser welding is also widely used in the production of metal parts, such as gears, engine valves, brake calipers and other key parts.

With the continuous development of the automobile manufacturing industry and the continuous innovation of technology, the application scope of laser equipment in the field of automobile manufacturing will continue to expand and become more in-depth. In the future, ANTISHICNC will be committed to providing more intelligent, automated and integrated laser processing equipment to bring more efficient and accurate solutions to the automobile manufacturing industry.

The advantages of laser processing equipment in the field of automobile manufacturing are mainly as follows:

1.Reduce production costs

1) Improve material utilization

Laser cutting equipment can achieve precise cutting of parts with complex shapes, effectively reduce material waste, and thus significantly improve material utilization. At the same time, laser welding and cladding technology can not only repair defects on the surface of parts, but also strengthen them and extend their service life, thereby indirectly reducing production costs.

2)Optimize production processes

Laser processing equipment has a high degree of automation capabilities, which can greatly reduce manual intervention and thus reduce labor costs. In addition, its high-precision processing characteristics can also reduce subsequent processing procedures and shorten production cycles, thereby significantly improving production efficiency.

2.Improve product quality

1) High-precision processing

Laser processing equipment, with its extremely high processing accuracy, can easily meet the strict requirements of the automobile manufacturing industry for component accuracy. Whether it is core components such as engines or exterior parts such as body covers, laser processing can ensure that the product’s dimensional accuracy and surface quality meet high standards.

2)Strengthen welding quality

Laser welding technology can achieve high-quality welded joints with significant advantages such as high strength, low deformation and good sealing. These characteristics help to significantly improve the overall quality and safety performance of automotive products.

3.Accelerate the product development cycle

1) Rapid prototyping

Laser processing equipment can quickly produce prototypes of parts and provide designers and developers with physical models for testing and verification. This feature helps to significantly shorten the product development cycle and speed up the launch of new products.

Flexible production

Laser processing equipment has a high degree of flexible production capacity and can quickly adjust production plans according to changes in market demand and product design. This enables automobile manufacturers to respond to market changes more flexibly and meet diverse customer needs.

4.Improve production safety

1) Non-contact processing

Laser processing is a non-contact processing method that does not cause mechanical damage to operators, thereby significantly improving the safety of the production process.

2) Reduce environmental pollution

The laser processing process generates less waste and is easier to handle. Compared with traditional processing methods, laser processing has less impact on the environment and is a more environmentally friendly processing technology.

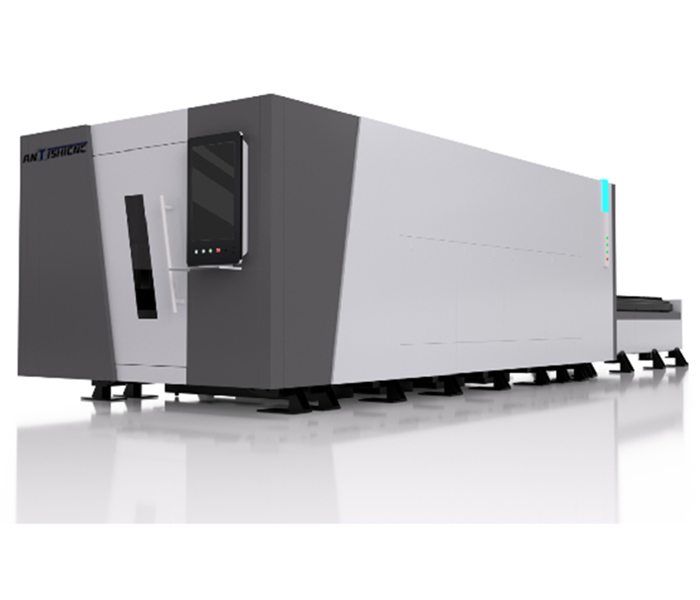

| Model | AT-3015E 6000w |

| Working Area | 3000mm×1500mm |

| X/Y/Z Travel | 3000/1500/150mm |

| Laser Wavelength | 1080nm |

| Laser Power | Raycus 6000W CE |

| Working Life of Fiber Source | More than 100000 hours |

| Laser Beam quality | <0.373mrad |

| Laser Cutting Head | Raytools Automatic Focus Laser |

| Position Type | Red Dot Pointer |

| Cutting Thickness | 0.5-22mm (for Large Quantity Process) |

| Max. Idle Running Speed | 150M/min |

| Geometric Position Accuracy | Within ±0.05mm/M |

| Reorientation Accuracy | Within ±0.03mm/M |

| Lubrication System | Electrical Motored |

| Min. Line Width | ±0.02mm |

| Power Consumption | ≤160KW |

| Transmit system | Dual Rack & Pinion type |

| Auxiliary Gas for Cutting/Assist system | Oxygen, Nitrogen, Air/Germany SMC |

| Compatible Software | AutoCAD, CorelDraw, etc. |

| Handle Control | WIFI Wireless Control Handle |

| Graphic Format | DXF/PLT/AI |

| Power Supply Voltage | 380V/3Ph/50Hz |

| Warranty | 2 Years |

If you are also a manufacturer of automobiles or related parts, welcome to consult ANTISHICNC, we will provide you with professional advice.