Pipe thread lathe, also known as pipe threading lathe machine, is a horizontal lathe specially designed for turning large-diameter pipe fittings. In order to facilitate the clamping and processing of large-diameter pipe fittings or rods, this product is widely used in mechanical processing operations in machinery manufacturing, petroleum, chemical, coal, geological exploration, urban water supply and drainage and other industries.

Pipe thread lathes are mainly divided into ordinary Pipe Threading Lathe and CNC Pipe Threading Lathe according to different control and operation methods. CNC Pipe Threading Lathe improve the processing efficiency and processing accuracy in the field of machining and manufacturing, and reduce the work intensity of workers.

Pipe Threading Lathe generally have a large through hole on the spindle box, and after the workpiece passes through the through hole, it is clamped by two chucks located at both ends of the main shaft for rotary motion. There are generally two ways to feed the tool: one is to drive the slide and tool holder located in front of the bed by the lead screw, the same as the ordinary lathe; the other is to use the flat comb on the slide at the center of the bed. The external thread cutting head of the knife (see automatic opening and closing thread cutting head) cuts into the workpiece and moves forward.

Some machine tools for processing long pipes also have workpiece support devices, such as center rests, heel rests, rear supports, etc.

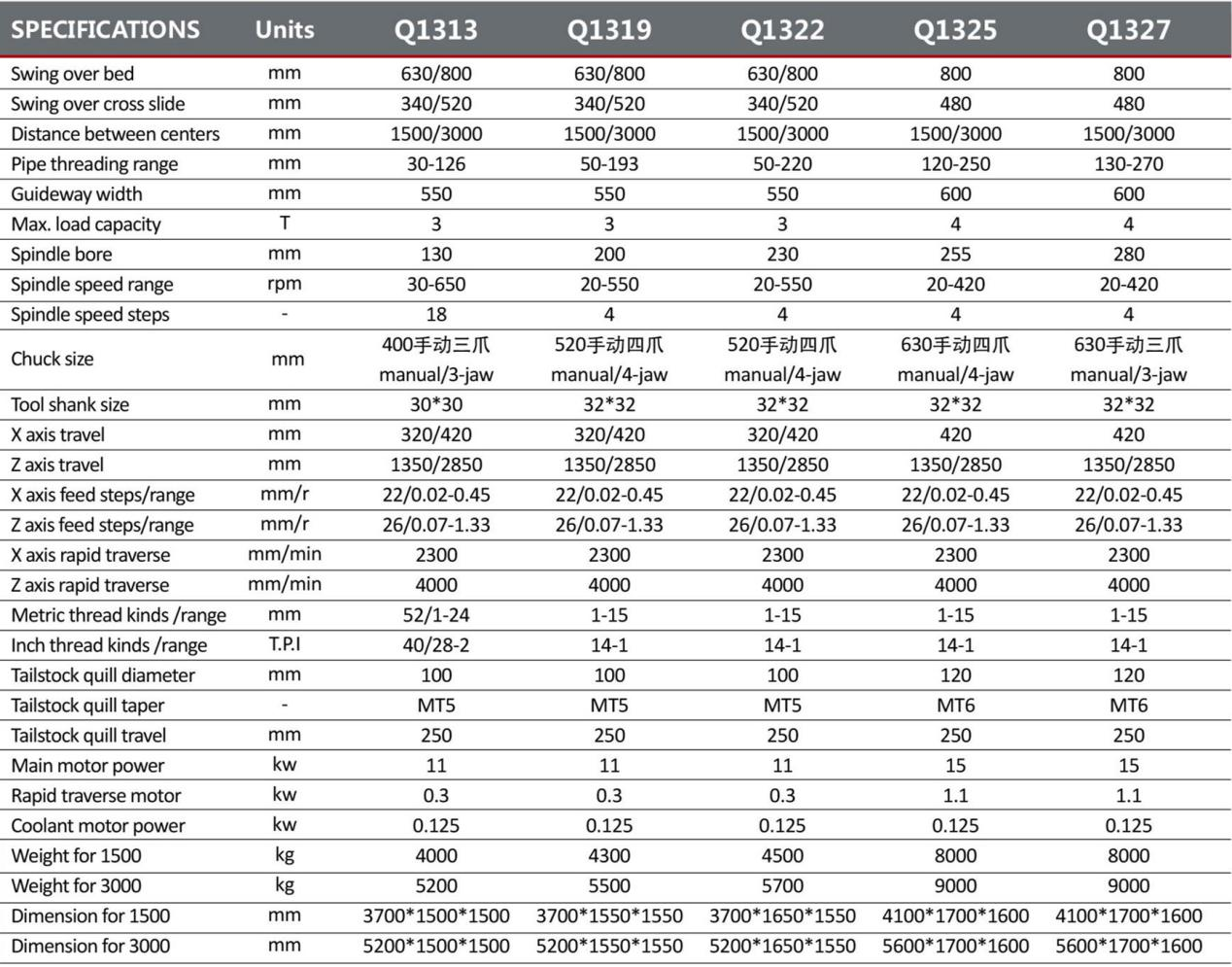

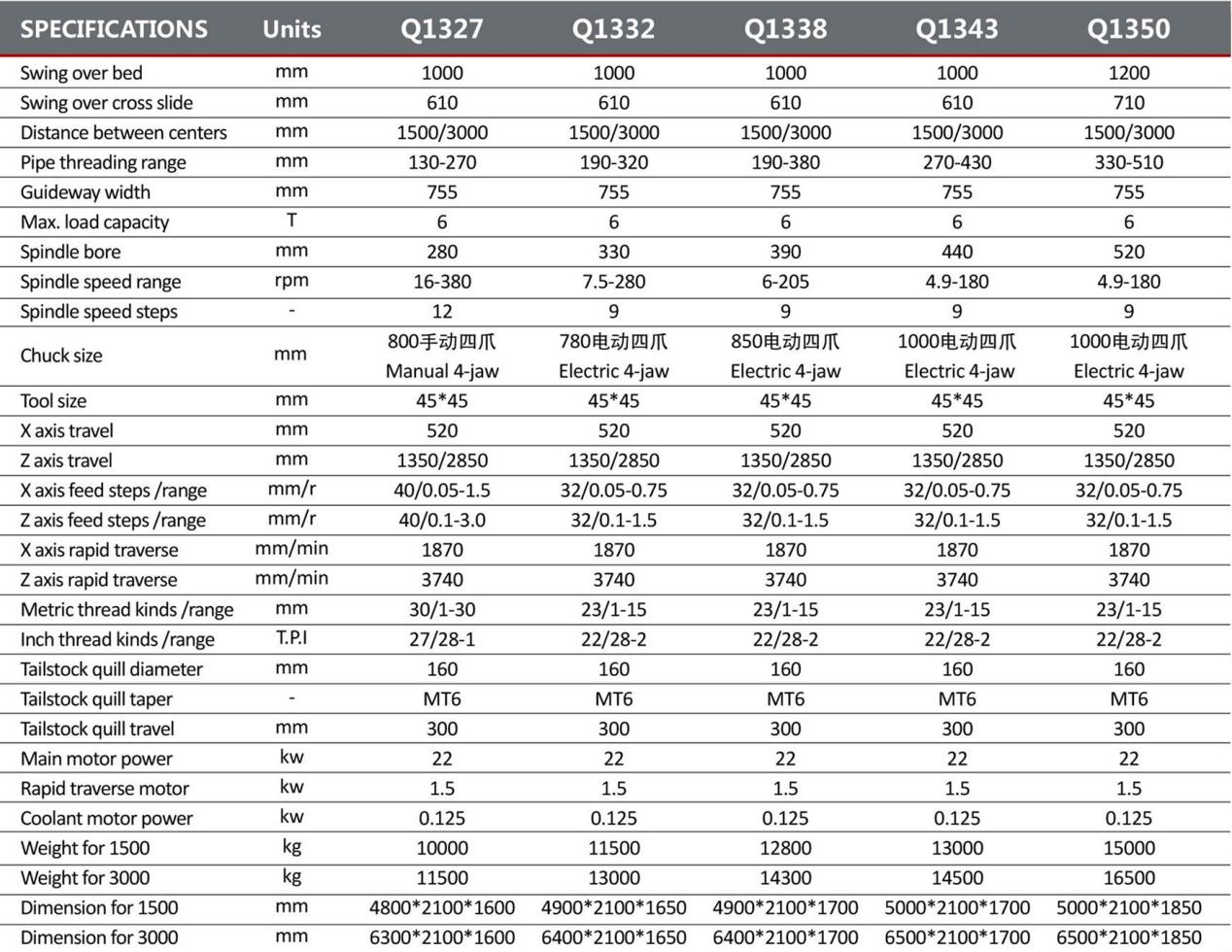

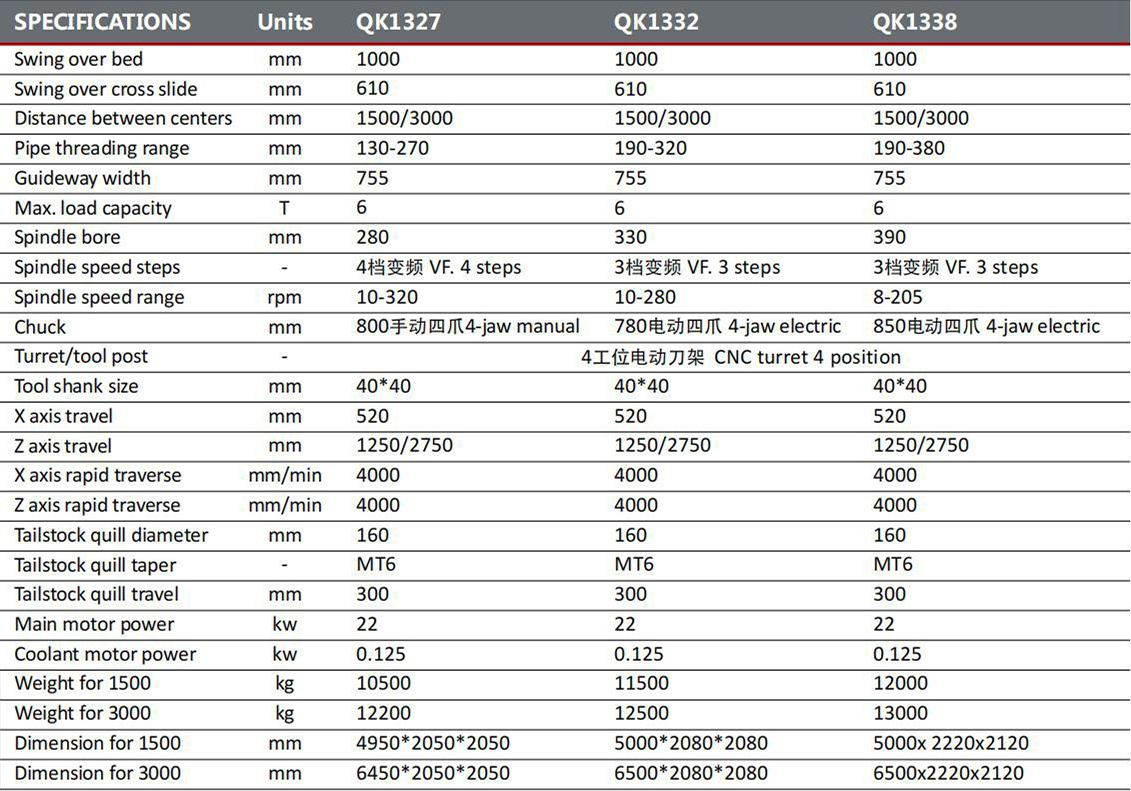

Main specifications of Pipe Threading Lathe:

The spindle diameter of the pipe thread lathe is mainly 135mm~500mm, the maximum turning diameter of the workpiece on the lathe is 630mm~1200mm, and the maximum workpiece length is 750mm~15000mm.

The main features of Shanghai ANTISHI ordinary pipe thread lathe are as follows:

1.Large spindle hole and double chucks can clamp and process large diameter pipes;

2.The whole bed is made of high-strength iron, with high rigidity and high precision;

3.Ultrasonic frequency quenching guide rail is hard enough and has good wear resistance;

4.Equipped with taper guide rod device, which enables the machine to process taper threads.

The main model parameters are as follows:

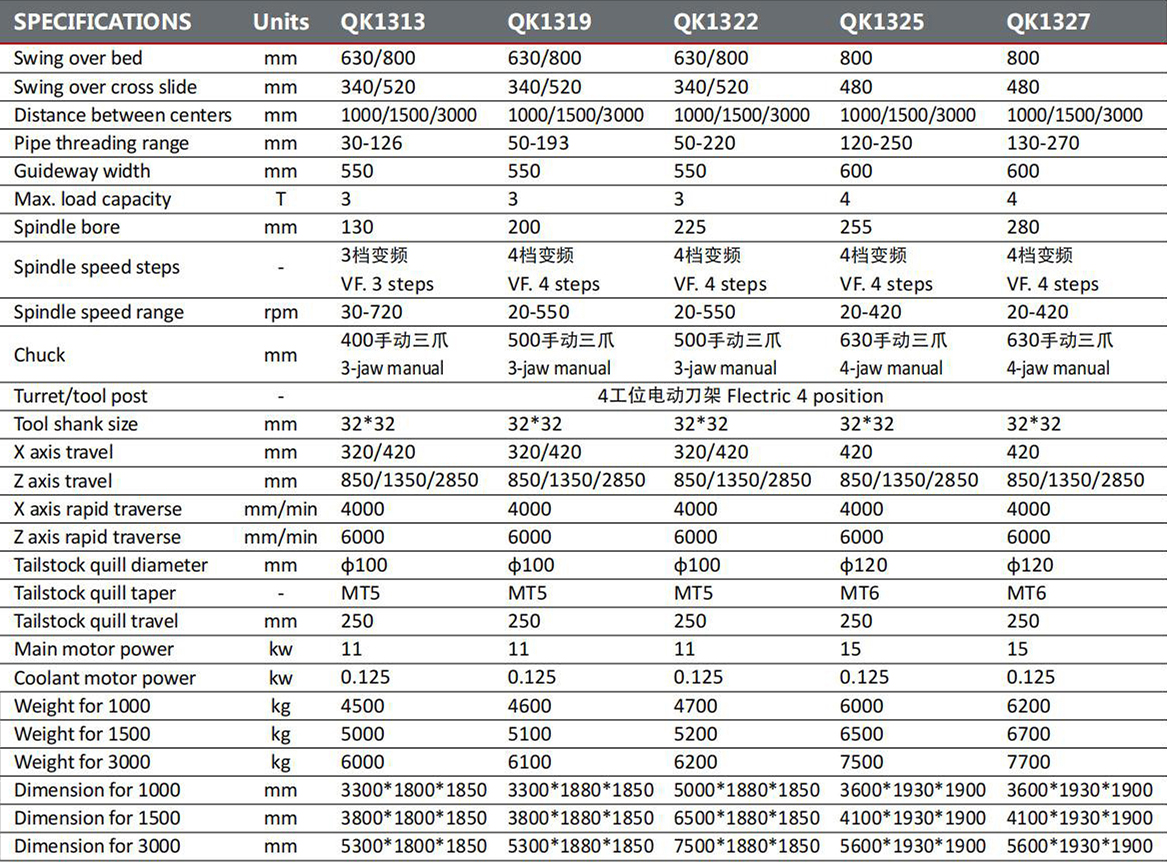

Shanghai ANTISHI CNC pipe thread lathe is suitable for all kinds of pipe thread turning, and can also be used as an ordinary CNC lathe to process complex-shaped bushings and disc parts.

The characteristics are as follows:

1.Tapered rolling bearing increases the rigidity of the main shaft.

2.Large spindle diameter, double chucks are set at the front and rear, and the electric chuck can be selected at will.

3.The surface of the bed slide rail is quenched by super audio frequency, which is durable and wear-resistant.

4.The saddle rails are treated with wear-resistant coating

5.There are two kinds of speed change: manual and step-less.

6.Set up self-lubricating system, easy maintenance

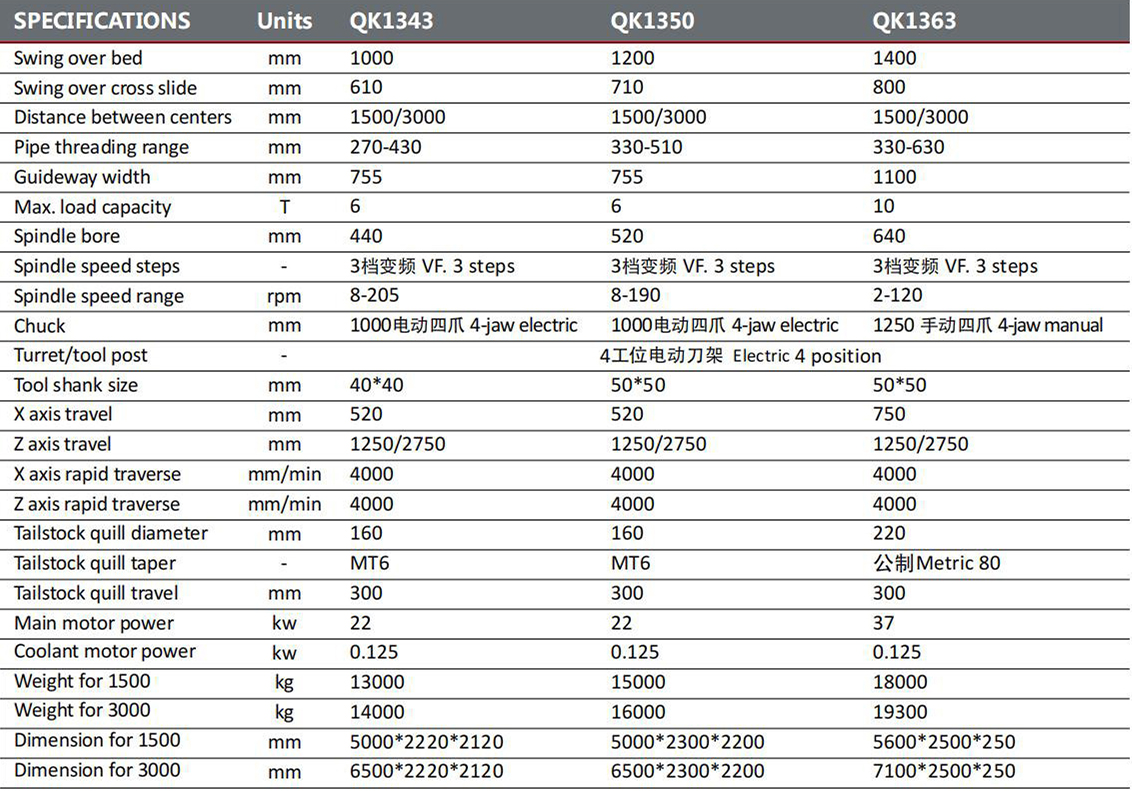

The main model parameters are as follows:

As a leading manufacturer of industrial lathe machinery and machine tools in China, Shanghai ANTISHI has 20 years of experience in machine tool production. The Shanghai ANTISHI sales team adheres to the principle of being responsible to customers and will always provide customers with the best solution.

If you have any questions or needs, please contact the Shanghai ANTISHI sales team! ! !

http://www.antsmachine.com

email:Contact@antsmachine.com