Recently , Shanghai ANTISHICNC received a request from a Brazilian tool processing company serving the entire Brazil and South America . The company manufactures and sells standard blades, as well as designs and develops special knives and blades based on customer needs.

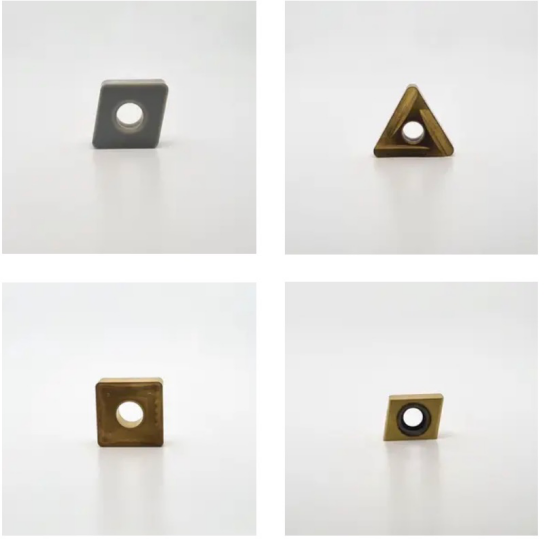

Customers mainly process 4 categories of products , special tools , standard tools , special tools , and standard tools . The customer found us from the official website and inquired whether we have machines that can process special profile grinding , peripheral grinding , and T-shaped chamfer grinding . During the communication , we got some drawings that the customer wanted to process . Under the analysis of our professional engineers , our C818 series five-axis CNC tool grinder can meet the customer’s processing needs after customizing a clamping handle according to the drawings . Taking into account the relatively large processing margin of the customer’s drawings , comprehensive processing efficiency and stability , we finally recommended 2 models, C818 Power and C818 Vision to the customer .

| Non-standard tools and standard tools produced by the customer company | |

|

|

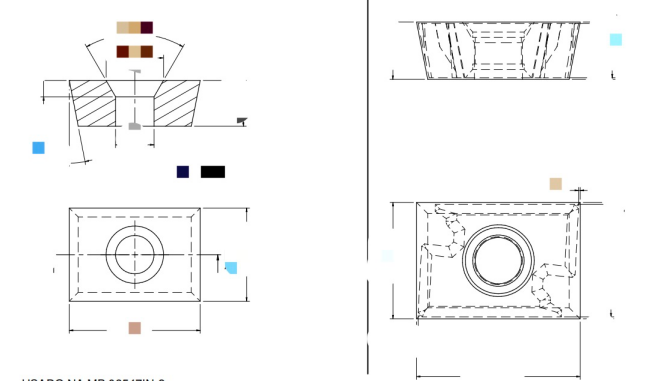

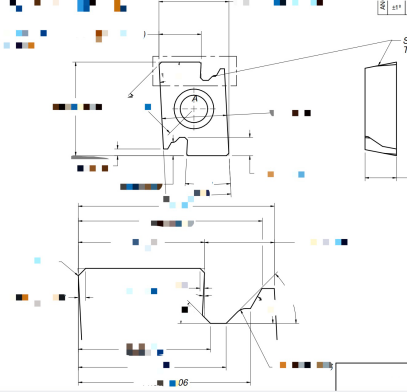

| Customer part processing drawings | |

|

|

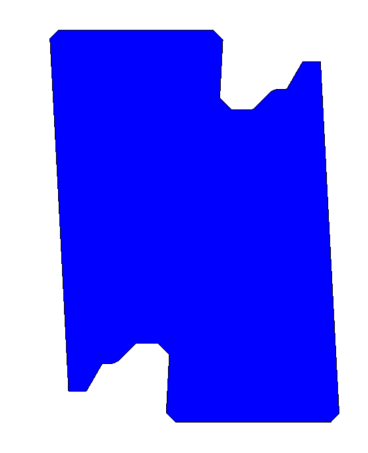

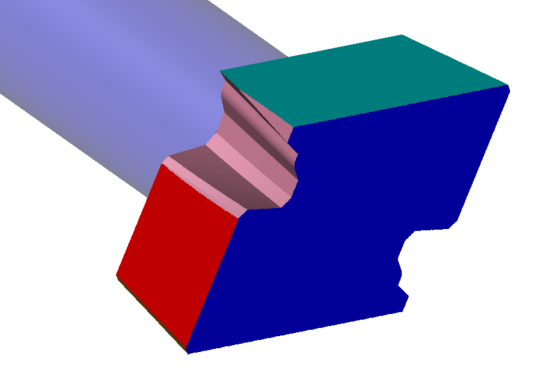

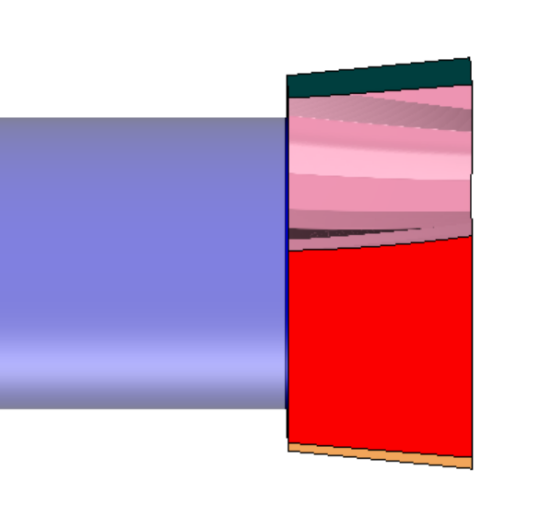

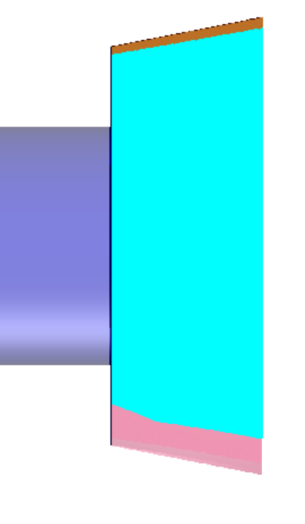

| ANTISHICNC C818 tool grinder system simulation diagram | |

|

|

|

|

| ANTISHICNC C818 series five-axis CNC tool grinder (milling cutter, drill bit, groove cutter, etc.) | |

|

|

|

|

C818 series tool grinders have a total of 3 models with the same functions. Models with different processing sizes, they are C818 Mini , C818 Power, and C818 Vision. The clamping range of this series is 3~32mm, and the tool processing range is 1~ 40 mm. It can also be equipped with an automated manipulator, which is efficiently and perfectly to meet customers’ processing needs. It can be widely used in 3C, medical, automobile, high-speed rail, aerospace, precision tool grinding and other fields.

C818 series tool grinders have the following features :

1.The machine tool adopts an integral mineral casting bed, servo motors and screw guides (heavy-duty roller type) imported from Japan, and high-torque DD motors for the A and B rotating axes.

2.The permanent magnet constant torque spindle motor, double grinding head structure, and B-axis can rotate 360 degrees are suitable for the processing and production of various non-standard tools.

3.Based on the excellent concept and design of German 5-axis CNC tool grinders.

4.Designed based on the integration of personnel’s practical experience and on-site guidance and exchanges.

If your company is also a manufacturer that processes various standard tools and non-standard tools and has similar tool processing needs , please feel free to contact us at any time . You can provide processing drawings, and our very professional engineers will comprehensively evaluate the drawings and recommend you a suitable machine based on the processing material, workpiece size, and processing requirements.