Milling machines, as a widely used metal cutting machine tool, have the main function of cutting workpieces through rotating milling cutters. Milling machines have a wide range of processing, and can process planes (horizontal planes, vertical planes), grooves (keyways, T-slots, dovetail grooves, etc.), toothed parts (gears, spline shafts, sprockets), spiral surfaces (threads, spiral grooves) and various curved surfaces. In addition, milling machines can also be used for cutting, milling planes and grooves.

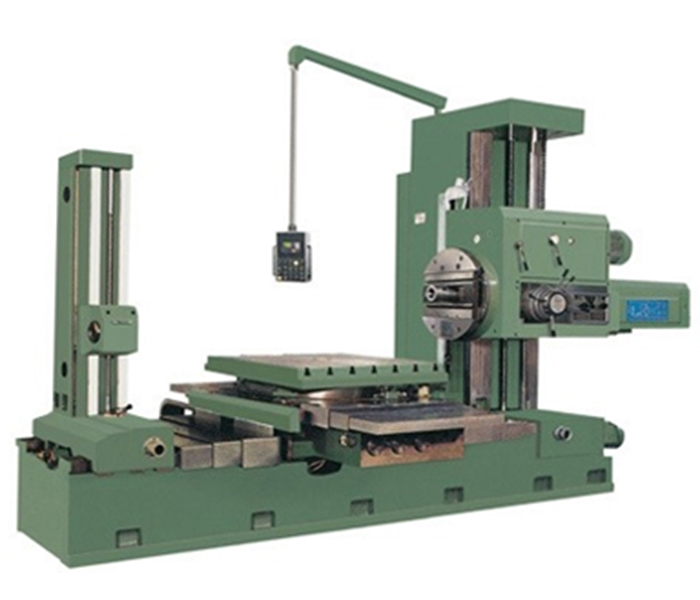

The milling machine consists of a bed, a worktable, a spindle, a feed mechanism, an electrical control system and other parts. The bed is the basic component of the milling machine, which bears the weight of the entire machine tool and ensures the relative position accuracy between the components. The worktable is used to install the workpiece and can move longitudinally, transversely and vertically along the bed rails to meet the processing requirements of workpieces of different sizes. The spindle is used to install the milling cutter and drive it to rotate at high speed to achieve cutting.

Ⅰ.The main functions of the milling machine

1.Plane processing: The milling machine can process various planes such as horizontal and vertical planes of the workpiece by installing different milling cutters. This processing method is widely used in the fields of machinery manufacturing, mold manufacturing, etc.

2.Groove processing: Using the milling cutter disc or forming milling cutter on the milling machine, grooves of various shapes, such as keyways, T-slots, dovetail grooves, etc. can be processed. These grooves play an important role in connecting and positioning mechanical parts.

3.Geared parts processing: Milling machines can also be used to process gears, spline shafts, sprockets and other geared parts. Through indexing heads or special fixtures, accurate indexing processing of these parts can be achieved.

4.Spiral surface processing: The spiral milling cutter on the milling machine can process spiral surfaces such as threads and spiral grooves. This processing method is widely used in the fields of machinery manufacturing, oil drilling, etc.

5.Cutting processing: Using the cutting tool on the milling machine, the workpiece can be cut. This processing method is suitable for the cutting needs of various materials.

Ⅱ. Application fields of milling machines

1.Machinery manufacturing industry: Milling machines play a vital role in the machinery manufacturing industry. From simple parts processing to complex mold manufacturing, milling machines can provide efficient processing solutions. For example, in automobile manufacturing, milling machines are used to process key components such as engine parts and chassis parts; in aviation manufacturing, milling machines are used to process high-precision parts such as aircraft frames and engine blades.

2.Mold manufacturing industry: Molds are indispensable tools in industrial production, and milling machines are one of the important equipment for mold manufacturing. Through milling machine processing, mold parts of various shapes, such as cavities, cores, sliders, etc., can be accurately manufactured. The quality of these mold parts directly affects the quality of the final product.

3.Electronic manufacturing industry: With the continuous upgrading of electronic products, the requirements for the processing accuracy and efficiency of parts are getting higher and higher. As one of the high-precision processing equipment, milling machines have been widely used in the electronic manufacturing industry. For example, in mobile phone manufacturing, milling machines are used to process mobile phone cases, buttons and other parts; in semiconductor manufacturing, milling machines are used to process high-precision parts such as silicon wafers and chips.

4.Energy industry: Milling machines also play an important role in oil drilling, wind power generation and other fields. For example, in oil drilling, milling machines are used to process key tools such as drill rods and drill bits; in wind power generation, milling machines are used to process parts such as wind turbine blades.

Ⅲ. The status of milling machines in the manufacturing industry

As one of the important equipment in the manufacturing industry, the status of milling machines is self-evident. With the continuous development and progress of the manufacturing industry, the requirements for processing equipment are getting higher and higher. Milling machines occupy a pivotal position in the manufacturing industry with their high precision, high efficiency and high flexibility.

First of all, the high-precision processing capability of milling machines enables them to produce high-quality products. In modern manufacturing, product quality is one of the key factors in the competitiveness of enterprises. Through precise processing control and high-precision measurement systems, milling machines can achieve high-precision processing and detection of workpieces, thereby ensuring the quality and performance of products.

Secondly, the high-efficiency processing capability of milling machines enables them to meet the needs of mass production. In modern manufacturing, mass production is one of the important means for enterprises to reduce costs and improve efficiency. By adopting advanced electrical control systems and efficient cutting technology, milling machines can achieve fast and accurate processing processes, thereby meeting the needs of mass production.

Finally, the high flexibility of the milling machine enables it to adapt to the processing needs of various complex parts. In modern manufacturing, with the increasing variety of products and the increasing complexity, the requirements for processing equipment are also getting higher and higher. The milling machine can achieve precise processing and manufacturing of various complex parts by adopting technical means such as multi-axis linkage and composite processing, thereby meeting the diverse needs of enterprises.

|

|

|

Antishi milling machines are available in many types, including conventional milling machines, CNC milling machines, and milling and boring machines, to meet the diverse needs of different customers.We can provide timely technical support, training and spare parts supply, welcome to contact us!