1. Work surface: U-shaped work surface, standard configuration of hardened work surface that is not easy to wear.

2. Operation table: Horizontal operation table, standard configuration of 19-inch horizontal operation table for intuitive operation, standard configuration of external keyboard, ergonomic design, easy-to-learn and easy-to-operate human-machine interface.

3. Grounding construction: To prevent electromagnetic interference and leakage, please follow the third type of construction specified in the electrical equipment standard (grounding resistance is below 10Ω) and separate grounding from other machines, using a 14mm² independent grounding wire.

4. Space requirements: When positioning the machine, pay attention to the size of the space and consider the range of movement for maintenance and use.

5. External environment requirements: Ideally control the air-conditioning room temperature to 23±0.5°C, humidity below 75%RH, avoid vibration sources, direct sunlight, near heat treatment or electroplating plants, and dusty environments.

6. Automatic wire threading: ANTISHICNC company CK series of slow wire EDM cutting machines are equipped with AWT automatic wire threading (3rd generation) as standard.

7. Four-axis code: Benchmark European and Japanese brand configuration.

8. Self-developed automatic wire threading system

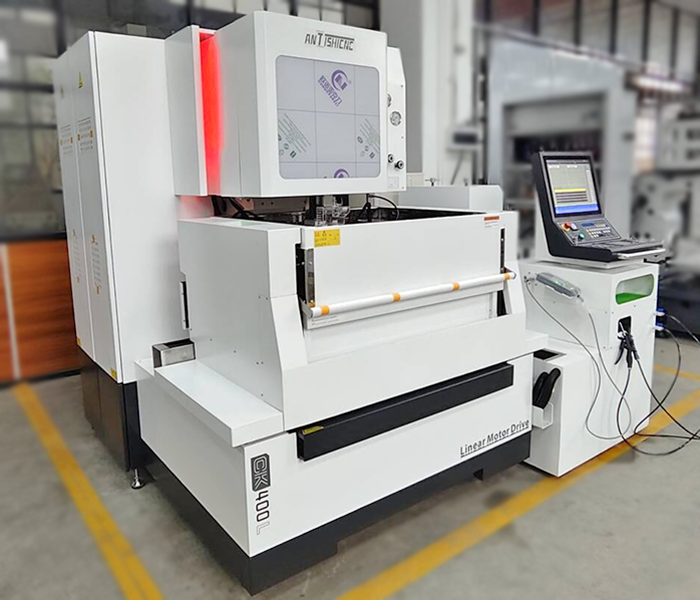

These technical parameters reflect the characteristics of the ANTISHICNC CK400L CNC five-axis slow wire EDM cutting machine, including the design of its work surface, the ergonomics of the operating table, environmental requirements, grounding construction standards and advanced automatic wire threading technology.

9. Wet WEDM wire cutting to ensure accuracy and finish: dimensional tolerance accuracy ≤5μm Ra≤0.58 μm

If you have questions and purchasing needs about slow wire cutting machine tools, wire cutting machines, EDM machines, and electrical machining machines, please contact the business personnel of ANTIS. The contact email is contact@antsmachine.com

The contact website is www.antsmachine.com

| MODEL | UNIT | CK400L |

| X, Y, Z axis travel [X, Y, Z] | mm | 400*300*260 |

| U, V axis travel [U, V] | mm | 80*80 |

| Maximum workpiece size [WxDxH] | mm | 960*690*255 |

| Workpiece weight | Kg | 400 |

| X,Y feed speed | mm/min | Max.1800 |

| Motor system | ASIS | X·Y axis linear motor/U·V·Z axis AC motor drive |

| Green Trail (Standard) | mm | ∅0.15-0.3(0.25) |

| Line Tension | gf | 300-2500 |

| Maximum cutting slope/work-piece thickness | — | ±17.8/80(wide angle nozzle DA+DB=15mm) |

| Mechanical net weight | Kg | 3750 |

| Processing fluid power system device | ||

| Filtration capacity | L | 650 |

| Filter method | – | Paper net |

| Diaozi resin filter | L | 14 |

| Water quality control | Auto | |

| Liquid temperature control | – | Auto |

| Processing power | ||

| Return way | Power MOSFET Transistor | |

| Maximum output current | A | 25 |

| current selection | A | 10 |

| off time | Sec | 50 |