The Swiss Type CNC Automatic Lathe is an advanced CNC machine tool. It can also be called a mobile spindle box CNC automatic lathe, an economical turn-milling machine tool or a slitting lathe. It is a precision processing equipment that uses a high-precision control system and a carefully designed structure. , can complete turning, milling, drilling, boring, tapping, engraving and other composite processing at the same time. It is mainly used for batch processing of precision hardware and special-shaped non-standard parts such as shafts. It is widely used in parts in electronics, communications, medical, home appliances and other industries.

The parts suitable for processing by the Swiss Type CNC Automatic Lathe are:

1. Shaft parts: The centrifugal machine is suitable for processing shaft parts, such as camshafts, crankshafts, universal joints, transmission shafts, etc., and can ensure the accuracy and surface quality of shaft parts.

2. Gears: Centrifugal machines can precisely process various types of gears, such as spur gears, helical gears, bevel gears, etc., which can greatly improve the transmission efficiency and accuracy of gears.

3.Mold parts: The centering machine has a high degree of stability and precision, and is suitable for processing high-precision mold parts, such as plastic molds, die-casting molds, engraving molds, etc.

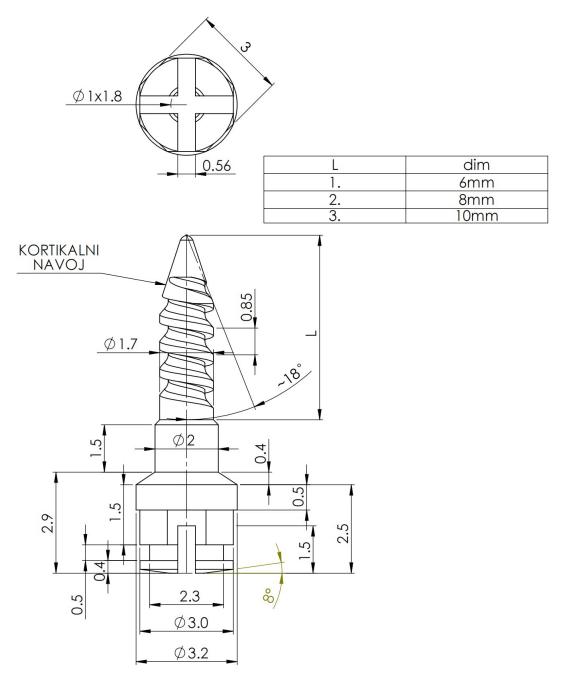

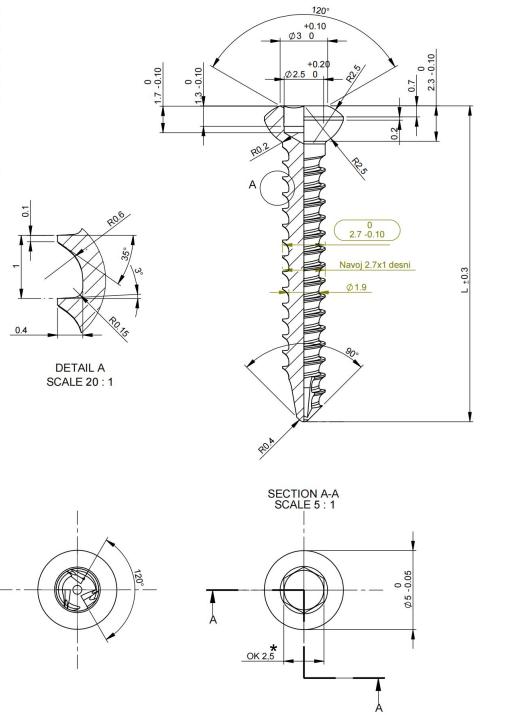

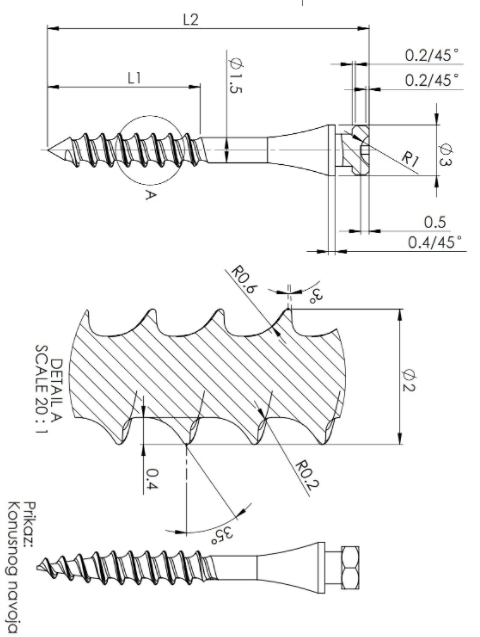

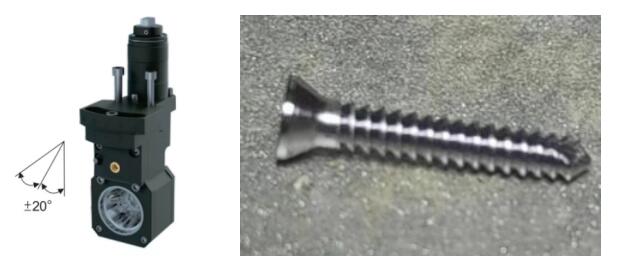

A Serbian customer who specializes in the production of medical bone screws approached the Shanghai ANTS team and hoped that the Shanghai ANTS technical team could develop a processing plan for their three bone screw parts based on their needs.

|

|

|

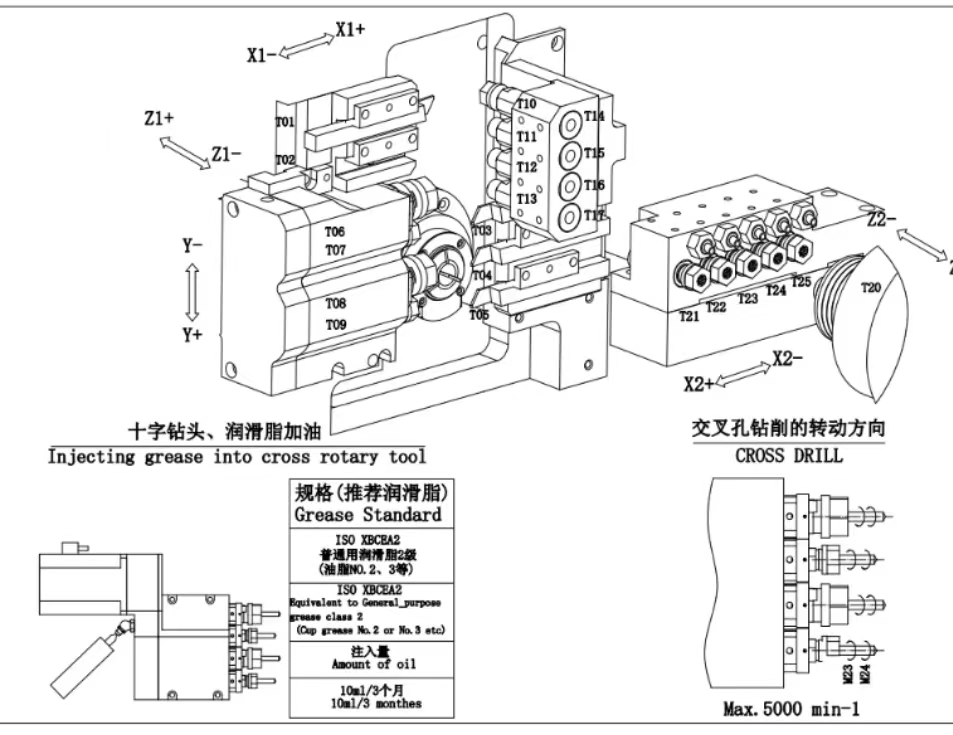

According to the customer’s drawings, the Shanghai ANTS sales team, with the cooperation of the technical team, selected the G205E model for the customer. The feed length of this model can reach 140mm at a time, the processing diameter is Φ2mm-20mm, and its targeted cutting tools The arrangement perfectly solves the customer’s processing requirements.

Because the customer’s workpiece has thread processing requirements, the customer discussed with the Shanghai ANTS team whether to install a thread whirling device. The thread whirling is a milling tool holder for multi-head tool processing. It is installed on the Swiss Type CNC Automatic Lathe and is mainly used to process threads. A six-knife cutterhead is added to the head, which allows multiple knives to process threads at the same time, improving processing efficiency. The price of an imported thread whirling is about 16,000 USD.

According to the customer’s workpiece drawings, The G205E Swiss Type CNC Automatic Lathe can process threads without adding a thread whirling. The thread whirling is highly efficient for processing threads with a large cutting amount, but is not efficient for processing small threads below M10. One product basically only saves a few seconds, and it requires changing the cutterhead to process different threads. One cutterhead is used for one kind of thread. If there are more specifications, dozens of types need to be prepared. If the cutter head and cutter grains are both made in China, the price will be around 1,700 USD, which is relatively high cost and not practical for customers. Therefore, the Shanghai ANTS team did not blindly ask customers to install it. Instead, they gave customers reference value based on their actual workpiece drawings. Opinion.

In the end, the customer chose the G205E model of the Swiss Type CNC Automatic Lathe with the help of the Shanghai ANTS team. Shanghai ANTISHICNC is committed to the development of the field of Swiss Type CNC Automatic Lathes and insists on bringing high-quality, cost-effective machines to customers, which not only fills the domestic market gap, and has brought high-quality and cost-effective products to more foreign customers.

Please contact the Shanghai ANTS team if you need any support!

Web: www.antsmachine.com

Tel/Whatsapp:+86-19534031668

Email:contact@antsmachine.com

Wechat:ANTISHICNC