CNC machining centers and CNC turn-mill centers (multitasking machines) are high-precision equipment widely used in modern manufacturing. While they share similarities in functionality and applications, they also exhibit distinct differences. This article analyzes their key similarities and differences:

Similarities

CNC System Control

Both utilize computer numerical control (CNC) systems for automated machining, enabling complex toolpaths and parametric operations through programming.

High-Precision Machining

Equipped with high-rigidity structures and precision spindles, both achieve tight tolerances (e.g., IT6-IT7) for critical components.

Multi-process Integration

Capable of completing multiple operations (e.g., milling, drilling, tapping) in a single setup, minimizing repositioning errors.

Complex Part Compatibility

Ideal for intricate components with multi-surface or multi-feature geometries, such as molds, aerospace parts, and precision machinery components.

Tool Management Systems

Feature automatic tool changers (e.g., disc-type or chain-type tool magazines) to enhance efficiency.

Differences

| Comparison Dimension | Machining centres | CNC Turning and Milling Machine |

| Core Functions | Milling, drilling, boring, etc., focusing on flat or three-dimensional contour machining. | Turning + milling combined function, both rotary body machining and milling capability. |

| Typical structure | Mostly vertical or horizontal layout, fixed or moving table (XYZ axis). | Integrated milling spindles (e.g. B-axis, Y-axis) on the basis of lathe, supporting rotary machining. |

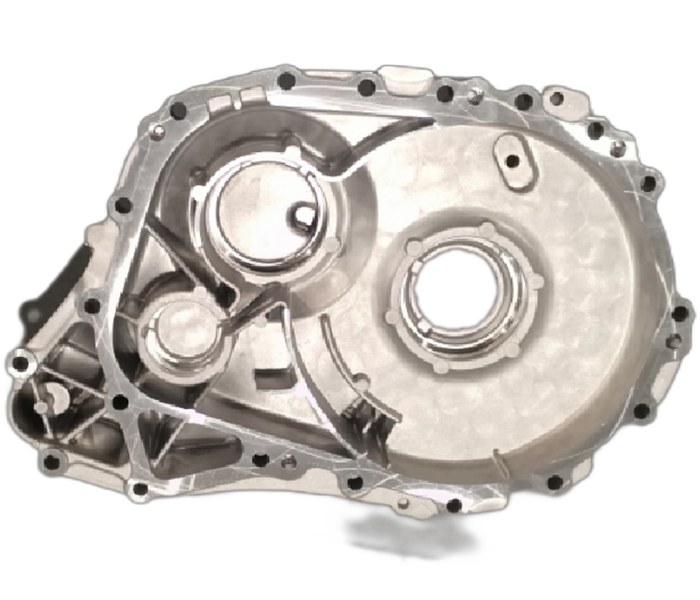

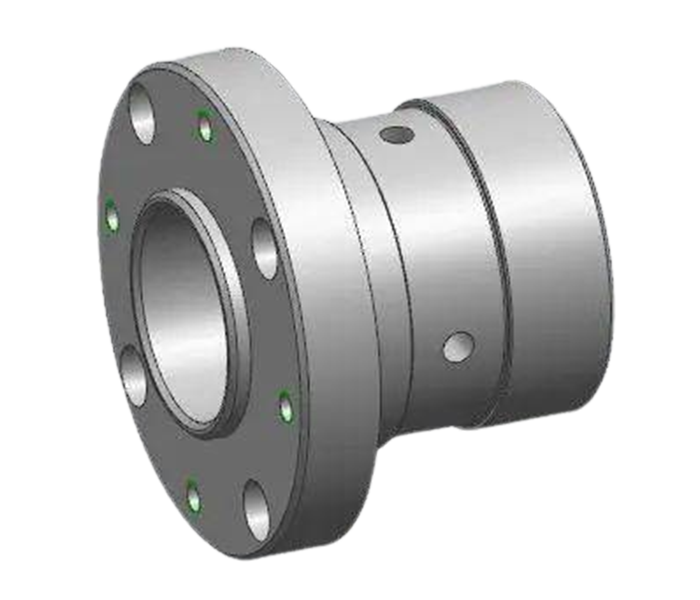

| Machining Objects | Non-rotating parts such as boxes, plates, moulds, etc. (e.g. engine blocks, mobile phone cases). | Rotary parts (e.g. shafts, discs), taking into account shaped features (e.g. keyways, helical grooves). |

| Spindle type | Milling spindle-based, high speed (up to tens of thousands of rpm). | Turning spindles (low speed, high torque) + milling spindles (high speed), supporting power tools. |

| Clamping method | Usually use flat jaws, fixtures or vacuum adsorption to fix the workpiece. | Mostly adopts chucks or centers to clamp rotary workpieces, and supports simultaneous machining of sub-spindles. |

| Typical applications | Multi-face machining, deep hole machining, complex surface machining. | Turning of external/internal holes + milling of faces/flanks, eccentric machining, thread milling, etc. |

| Programming complexity | Need to deal with multi-axis linkage (3-axis/5-axis), but mainly milling path. | Requires simultaneous programming of turning and milling, and more complex logic for complex machining (e.g. polar co-ordinate programming). |

| Cost and efficiency | Suitable for multi-species, small batch of complex parts, high efficiency of single process. | Suitable for full process machining of large quantities of rotary parts, reducing equipment changeover time. |

Summary of core differences

Functional Focus

Machining centre: milling-based, suitable for non-rotary parts.

Turning and milling compound: turning + milling, suitable for multi-process compound processing of rotary parts.

Structural design

Machining centre: the spindle is fixed or mobile, and the worktable carries the workpiece.

Turning and milling compound: integrated lathe spindle and milling power head, supporting workpiece rotation and tool linkage.

Machining efficiency

Turning and milling composite can complete the whole process of turning, milling and drilling for rotary parts in one clamping, reducing the time of changing machines;

Machining centres have more advantages in complex curved surfaces or multi-face machining.

Suggestions for selection

Selection of machining centres

When the machining object is mainly non-rotary parts, such as all kinds of moulds, shells, etc., and the machining process needs to use a lot of multi-axis linkage technology or involves the machining of complex surfaces, the machining centre will be the ideal choice. Its powerful milling function and flexible multi-axis control capability can meet the requirements of high precision and complex shape machining of such parts.

Selection of mill-turn compound

If the processing object to rotary parts, such as shafts, disc parts, and need to be integrated in the same equipment turning, milling, drilling and other processes, to achieve the whole process of machining, CNC mill-turn composite machine tool is undoubtedly the best choice. It can complete a variety of machining operations in a clamping, effectively improving processing accuracy and productivity.

In the actual production application, enterprises should take into account the specific characteristics of the parts, production batch, cost budget and the overall process route optimisation and other factors, carefully make equipment selection decisions to ensure that the selected equipment can maximize to meet the production demand, enhance the production efficiency and market competitiveness of enterprises.

Keywords: CNC lathe, CNC machine tool, CNC Turning and Milling Machine, Machining centre, CNC machining centre