|

|

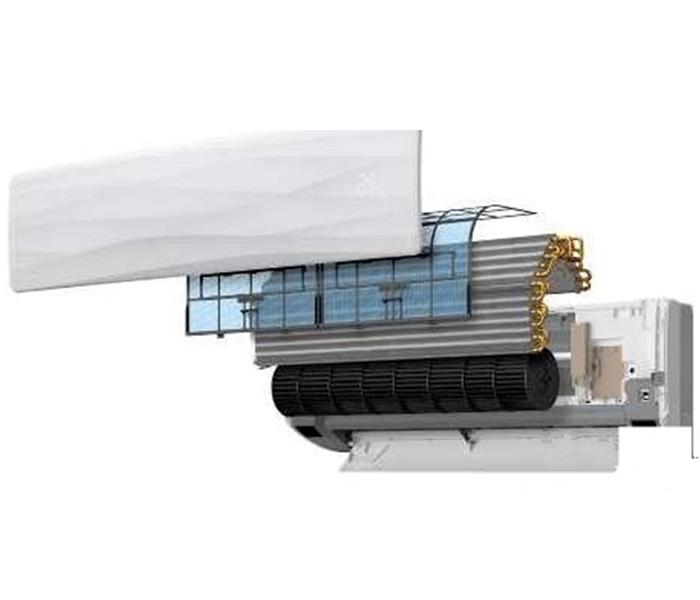

The outer shell of the air conditioner or some internal metal air ducts usually use CNC plate rolling machines to bend the flat metal plates into specific shapes and curvatures according to design requirements to meet the shape of the outer shell or the structural needs of the air duct, making the manufacturing of air conditioner components more accurate and efficient. When choosing air conditioner materials suitable for plate rolling machine processing, two aspects should be considered:

1.Ductility of Air Conditioner Materials

Materials with good ductility can withstand large deformations and are not prone to cracks or breaks when bent by plate rolling machines. For example, aluminum alloy materials have good ductility and are suitable for processing air conditioner components with complex shapes and large bending degrees, such as some decorative housings of air conditioners or more delicate internal air duct components.

2.Thickness of Air Conditioner Materials

It is necessary to consider whether the thickness of the material meets the processing range of the plate rolling machine. Different types of plate rolling machines have different processing limits for material thickness. If the material is too thick, it may exceed the processing capacity of the CNC plate rolling machine, resulting in reduced processing accuracy or equipment damage; if the material is too thin, problems such as excessive bending or wrinkling may occur during processing. Generally speaking, for the shell parts of small air conditioners, it is more appropriate to use materials with a thickness of 0.8 – 1.2mm.

After determining the material, it is time to choose a plate rolling machine. Here, Shanghai ANTISHICNC engineer recommend a CNC four-roller plate rolling machine suitable for air conditioner processing. The model reference is as follows:

| Model | W12-16×3000 |

| Upper roll diameter | Φ320mm |

| Lower roll diameter | Φ300mm |

| Side roll diameter | Φ250mm |

| Maximum rolling plate thickness | 16mm |

| Maximum pre-bending thickness | 12mm |

| Maximum coil width | 3000mm |

|

|

This W12-16×3000 CNC plate rolling machine has strong processing and forming capabilities. For the outdoor unit shell of the air conditioner, the internal metal air duct and other parts that require specific shapes and curvatures, it can accurately bend the metal sheet into the required shape and can achieve continuous bending processing. The CNC plate rolling machine can also automatically complete the curling process according to the preset program. For the processing of a large number of metal parts in air conditioning manufacturing, the high efficiency of the plate rolling machine can effectively shorten the production cycle and improve production efficiency.

Welcome to your consultation!

Keywords: Plate rolling machine, CNC plate rolling machine, four-roller plate rolling machine