To calculate press brake tonnage, you need to use a standard calculation formula based on the sheet material, thickness, bending length, and die opening width. The core principle is to derive the required pressure from the material’s mechanical parameters.

1.Core Calculation Formula (applicable to mild steel, the most common scenario)

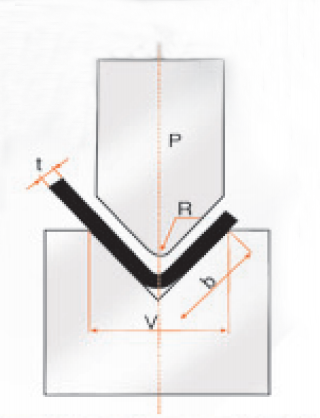

P = (650 *S² *L) /V

| Meaning | Unit | Definition | |

| P | Bending Pressure | KN | – |

| S | Plate Thickness | mm | Actual thickness of the sheet to be bent |

| L | Plate width | m | Effective length to be bent (not the total length of the sheet) |

| V | Bottom die groove width | mm | Die opening size (usually 8-10 times the sheet thickness, subject to the actual die size) |

2.Adjusting Coefficients for Different Materials

The “650” in the formula is the coefficient for mild steel. For other materials, replace it based on tensile strength. Common material coefficients are as follows:

Mild Carbon Steel (Q235/SPCC): 650

Stainless Steel (304/316): 1000 (higher strength, requires a larger tonnage)

Aluminum Alloy (6061/5052): 350 (lower strength, requires a smaller tonnage)

3.Calculation Example

Take “bending a 1000mm long, 5mm thick Q235 steel plate using a 40mm opening” as an example:

P = (650 × 5² × 1000) ÷ 40 = (650 × 25 × 1000) ÷ 40 = 406.25 kN = 40.625 tonnes

When selecting a press brake, round up the value (for example, if selecting a 40T or 50T press brake, avoid overloading).

If you have any questions about calculating the tonnage of a press brake, or are unsure about how to choose the right press brake, please contact Shanghai Ants Machine Co., Ltd. We will provide you with professional advice. Please contact us at contact@antsmachine.com.

Keywords: press brake, CNC press brake, hydraulic press brake, press brake tonnage, tonnage calculation