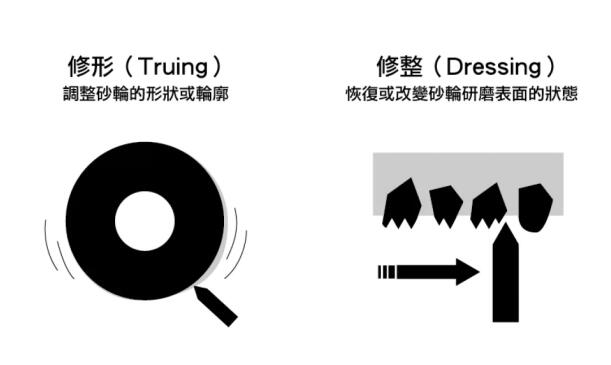

Distinguish between Truing and Dressing

Truing and dressing are generally considered to be the same process, and sometimes they are used interchangeably when discussing the terms of shaping or dressing procedures. This may be because, with the exception of some resin bond or metal bond products, most grinding wheels need to leave the production line before dressing and then reinstalling, so the two operations of dressing and dressing are usually carried out at the same time. .

However, these two operations are two different processes.

Modification is to deal with the “shape or contour of the grinding wheel”. When using a new grinding wheel, it is necessary to “change the state of the grinding surface” through dressing to make the abrasive work.

The conventional shape modification in the grinding process can correct the contour of the grinding wheel and compensate the shape loss caused by the general use of the grinding wheel. Correctly dressing the grinding wheel allows the workpiece to maintain the correct contour, geometry and size to meet the required specifications.

Although we often use “Dressing” to describe Truing and Dressing, Dressing refers to restoring or changing the “state of the surface of the grinding wheel”. After dressing, the grinding wheel can restore or change the cutting force of the grinding wheel or the ability to change the surface roughness of the workpiece.

If you want to use the grinding wheel to remove the workpiece, the wheel surface must be trimmed to expose the new abrasive and sharp points. The grinding wheel can cut with stronger cutting force. But on the contrary, it may make the surface rough and the roughness effect is not ideal.

The grinding wheel trimmed to this state is called “open”.

If you want to get a specific surface finish, the direction of dressing is to round or blunt the tip of the wheel surface. Then increase the friction of the grinding wheel to obtain the required surface finish. It should be noted here that although the surface treatment effect is very good, the removal rate of the workpiece is very small.

The grinding wheel that is dressed in this state is called “passivation closed”.

It is also important to understand how to choose the right diamond tools for grinding operations.