On the stage of modern mechanical processing, the slotting machine, as a classic processing equipment, occupies an important position in metal forming processing. With the advancement of the technological wave, the emergence of CNC slotting machines has brought huge impacts and changes to traditional ordinary slotting machines.

1.The Wide Application of CNC Slotting Machines in Metal Processing

CNC slotting machines, relying on their high degree of automation and precise numerical control capabilities, play an indispensable role in many key metal processing fields.

In the aerospace industry, the processing requirements for various aircraft components are extremely high. CNC slotting machines can accurately machine complex keyways, tooth profiles, and special formed surfaces on components such as aero-engine turbine discs, blades, and aircraft landing gears. For example, when machining high-precision tenon grooves at the root of turbine blades, the tolerances can be controlled within a very narrow range, ensuring the tightness and reliability of the connection between the blades and the turbine disc to withstand extreme conditions such as high temperature, high pressure, and high-speed rotation, thus providing a solid guarantee for the safe flight of aircraft.

The machine tool manufacturing industry is also an important application area for CNC slotting machines. During the processing of key components such as machine tool spindles and transmission shafts, CNC slotting machines can efficiently complete the slotting tasks of keyways, splines, and planes. Through precise programming control, the fitting accuracy between various components can reach the micron level, thereby enhancing the performance and processing accuracy of the entire machine tool, meeting the stringent requirements of modern manufacturing for high-precision machine tool equipment.

The automotive manufacturing field also cannot do without the assistance of CNC slotting machines. In the production of core components such as engines and transmissions, CNC slotting machines are used to machine the keyways and tooth profiles on components such as crankshafts and gear shafts. They can ensure processing accuracy while achieving high-speed and mass production, effectively improving the production efficiency and quality stability of automotive components, laying a solid foundation for the high performance and reliability of automobiles.

2.The Comparison and Differences between CNC Slotting Machines and Ordinary Slotting Machines

Processing Accuracy

CNC slotting machines can precisely control parameters such as the position, depth, and speed of slotting through advanced numerical control systems. For example, when machining metal keyways, the width tolerance can be controlled within ±0.02 mm, the depth tolerance can reach ±0.01 mm, and the geometric tolerance can also meet extremely high standards, ensuring high-precision fitting of components.

Ordinary slotting machines mainly rely on manual operation of mechanical transmission devices. Due to human operation errors and the limitations of the mechanical structure itself, their processing accuracy is relatively low. In the same keyway machining task, the width tolerance of the keyways machined by ordinary slotting machines may be around ±0.1 mm, and the depth tolerance is also larger, making it difficult to meet the requirements of modern metal processing for high accuracy.

Processing Efficiency

CNC slotting machines have significant advantages in processing efficiency. Taking the batch processing of metal parts as an example, the X and Y servo-controlled feed systems of CNC slotting machines can achieve rapid positioning and stepless speed regulation. Coupled with powerful slotting main motors, they can complete a large amount of slotting work in a short time. Moreover, due to their high degree of automation, there is no need for frequent human intervention, reducing the downtime during the processing process and greatly improving the overall production efficiency.

The processing efficiency of ordinary slotting machines is relatively low. Operators need to manually adjust the reciprocating motion speed of the ram and the feed amount of the worktable. Each change of processing parameters requires a certain amount of time, and operation errors are prone to occur during the processing process, leading to processing interruptions or the production of defective products, which seriously affects the processing efficiency.

Operational Convenience

The operation of CNC slotting machines is relatively convenient. Operators only need to input the corresponding processing parameters and programs into the numerical control system, and the machine tool can automatically process according to the set requirements. For example, the KND1000MF numerical control system adopted by BK5035 has the function of full-screen editing with Chinese character prompts, enabling even operators who are not very familiar with programming to operate relatively easily. At the same time, the equipped electronic handwheel facilitates the tool setting operation, further improving the operational convenience.

The operation of ordinary slotting machines requires operators to possess a high level of skills and rich experience. Operators need to manually operate various handles and buttons to control the movement of the machine tool and precisely adjust parameters such as the stroke of the ram, the slotting speed, and the feed amount. This not only requires operators to be familiar with the mechanical structure of the machine tool but also requires them to have a good sense of touch and judgment ability. The operation is difficult and the labor intensity is high.

Processing Flexibility

CNC slotting machines have strong processing flexibility. They can quickly adapt to the processing of metal parts with different shapes, sizes, and process requirements by modifying the numerical control program. For example, when it is necessary to switch from machining keyways to machining tooth profiles or special formed surfaces, only the program parameters need to be adjusted in the system, and the machine tool can quickly switch the processing mode without the need to replace a large number of tooling fixtures.

The processing flexibility of ordinary slotting machines is relatively poor. Due to the relatively fixed mechanical structure and transmission mode, for different processing tasks, it is often necessary to replace different tools, fixtures, and even readjust and recalibrate the machine tool. This process is time-consuming and laborious, limiting its application in diversified metal processing tasks.

3.Shanghai ANTISHICNC CNC Slotting Machine

Function and Structural Characteristics of BK5035:

Powerful Function Combination

BK5035 not only has the ability to machine various keyways but also can perform high-precision slotting of tooth profiles and complete the processing tasks of planes and formed surfaces. Whether it is a simple straight keyway, a complex spline keyway, a spiral groove, or various special-shaped tooth profiles and curved surfaces, it can handle them with ease. In the metal processing of machine tool manufacturing, automotive manufacturing, and other industries, it can realize the integrated processing of multiple procedures, greatly improving production efficiency and processing accuracy.

Advanced Numerical Control System and Convenient Operation

It adopts the well-known KND1000MF numerical control system, which has rich functions and a user-friendly operation interface. Its full-screen editing function with Chinese character prompts makes programming simple and easy to understand. Operators can easily write programs according to processing requirements. The equipped electronic handwheel provides great convenience for tool setting operations. Operators can quickly and accurately adjust the tool position, shortening the tool preparation time and improving processing efficiency.

Efficient and Reliable Transmission and Power System

The main transmission adopts a crank mechanism. Through one-stage synchronous belt deceleration and two-stage gear deceleration, the power of the main motor is stably transmitted to the slotting part, which can ensure the accuracy of slotting and provide sufficient cutting force. The X and Y feed adopts servo-controlled ball screws directly connected to the motor, realizing the stepless speed regulation function, making the movement of the worktable more stable and accurate. The 5.5KW high-torque servo motor used as the slotting main motor has a powerful power output and can easily handle the slotting processing of various metal materials. Whether it is high-hardness alloy steel or better-toughness non-ferrous metals, it can achieve efficient and high-quality processing.

Precise Mechanical Structure Design

The X and Y-axis ball screw pairs adopt a double-nut preloading structure. This design effectively solves the clearance problem between the screw and the nut. Operators can conveniently adjust the clearance between the screw and the nut and control it within a very small range, thereby improving the positioning accuracy and repeat positioning accuracy of the machine tool. It ensures that the machine tool can always maintain stable processing accuracy during the long-term metal processing process. At the same time, it also extends the service life of the ball screw pair and reduces the equipment maintenance cost.

Strict Precision Standard and Perfect Protection

BK5035 strictly conducts precision inspection in accordance with the JB/T2825.3 – 2006 mechanical industry standard, ensuring the processing accuracy of the machine tool from the source of production and providing reliable quality assurance for users. The machine tool adopts a full protection design, effectively preventing chip splashing and coolant overflow during the metal processing process, protecting the safety of operators and reducing the pollution of the processing environment. In addition, a chip removal device can be optionally equipped to timely clean up the chips generated during the processing process, keep the processing area clean, and further improve processing efficiency.

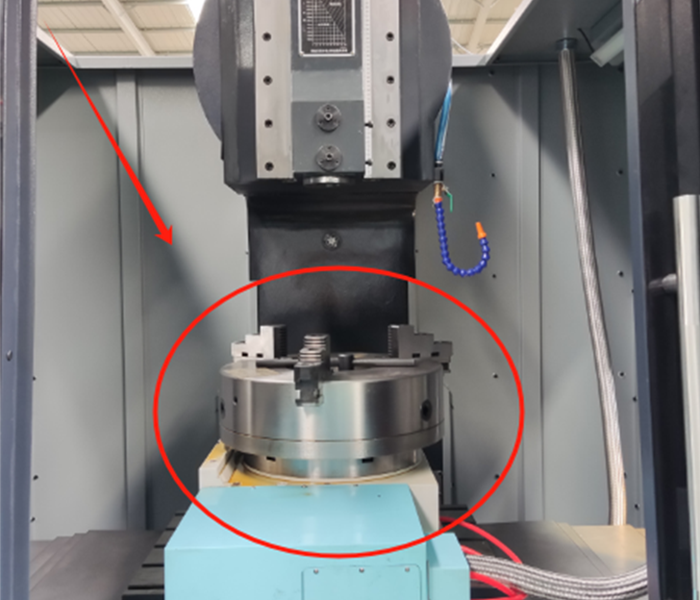

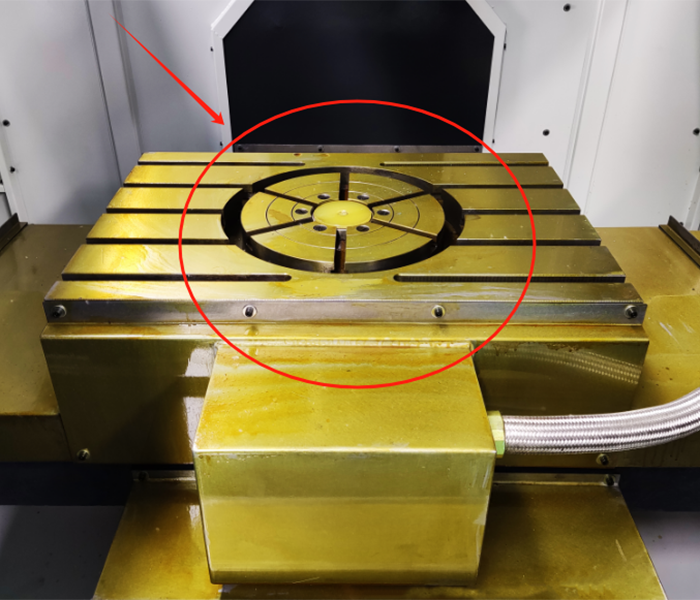

Regarding the BK5035 CNC slotting machine, we need to obtain the photos and drawings of the customer’s workpiece. We will help the customer confirm whether a rotary worktable is required for his processing needs and its size.

| Without spindle, the work table of the standard machine is as follows | There are two types of tables for retrofitting CNC rotary tables (directly on the table, and built into the table) (1) Directly on the table | (2)Built into the worktable |

|

|

|

| Specification | Unit | BK5035 |

| Maximum slotting length of ram | mm | 350 |

| Adjustable stroke of ram | mm | 300 |

| Movement times of ram | n/min | 0-70 |

| Maximum cutting force | N | 7500 |

| Worktable size | mm | 750x510 |

| Worktable stroke (X, Y) | mm | 320x400 |

| Tool shank diameter | mm | φ60 |

| Distance from the axis of the tool head support hole to the front arm of the column | mm | 625 |

| Distance from the bottom of the carriage to the worktable surface | mm | 680(Standard) 830(Height-Enhanced) |

| Distance from the bottom of the carriage to the worktable surface for BK5035Z with built-in rotary table | mm | 560(Standard) 710(Height-Enhanced) |

| Motor torque in X direction | N.M | 10 servo |

| Motor torque in Y direction | N.M | 15 servo |

| Rapid traverse (X) | m/min | 5 |

| Rapid traverse (Y) | m/min | 5 |

| Ball screw (X) | FFZD4010-3/P4 | |

| Ball screw (Y) | FFZD4010-3/P4 | |

| Power of main motor | KW | 5.5 servo |

| Weight (Net weight/Gross weight) | Kg | 4600/4750 |

| Machine dimensions | mm | 2550×2100×2500 |

| Packing dimensions | mm | 2700×2250×2700 |

In summary, CNC slotting machines have obvious advantages over ordinary slotting machines in the field of metal processing. Our BK5035 CNC slotting machine, with its excellent functional characteristics, advanced structural design, and good cost performance, has become an ideal equipment for processing metal materials in industries such as machine tools, automotive manufacturing, mechanical and electrical, and aerospace. It will bring higher efficiency, better quality, and stronger competitiveness to your metal processing business.

If you need a CNC slotting machine, welcome to consult Shanghai ANTISHICNC. We have rich experience in manufacturing and and application of slotting machine, and can provide you with professional technical support.

More CNC slotting machine equipment, please visit https://www.antsmachine.com/ or send email to contact@antsmachine.com. Our engineers will give you a very perfect solution.

Keywords: Metal processing slotting machine, Precision CNC slotting machine, Ship propeller CNC slotting machine, Aero-engine blade CNC slotting machine, Automobile engine part CNC slotting machine, Automobile transmission part CNC slotting machine