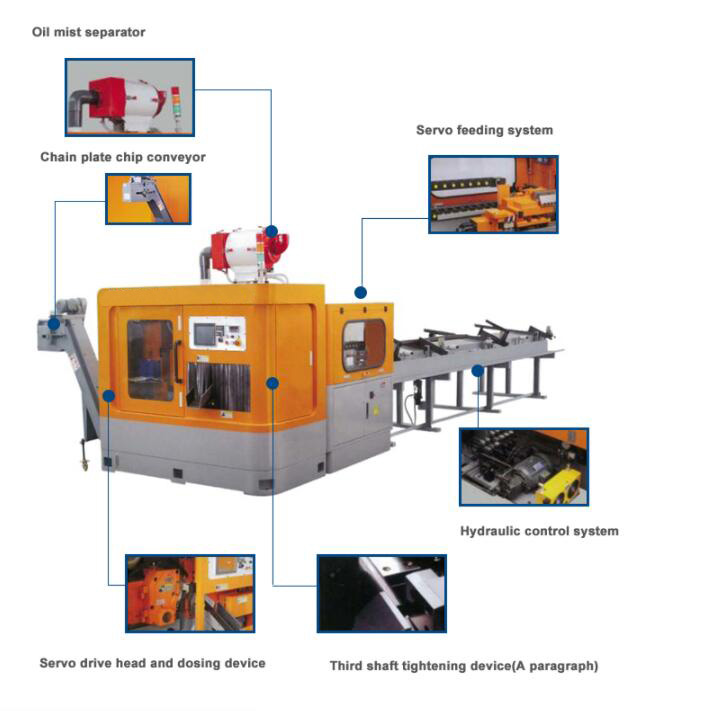

High speed metal/steel cutting fully numerical control fast aluminum stainless cutting circular saw machine

Introduction to machine tool and supplier parts

1.The machine adopt Mitsubishi control system

2.The main motor11KW Siemens motor motor.adopt Mitsubishi frequency convert, ensure motor stability and output adequately.

3.Cutting shaft motor adopt 2KW Mitsubishi server motor,feed motor adopt 1.5KW Mitsubishi servo motor,fully equipped with Mitsubishi actuator.

4.Low voltage electric appliance adopt Schneider and Siemens.

5.Adopt 10 inch Mitsubishi touch view screen.

6.Cutting shaft adopt HIWIN roller guide,ensure cutting rigidity.feed shaft adopt HIWIN spherical guide rail.deflection apparatus adopt HIWIN spherical guide rail.

7.Bearing structure adopt NSK/NTN

8.The gear structure import from TAIWAN.

|

Item |

NST-P90 |

|

Cutting capacity(mm) |

Bar 20-90 Angle material 20-70 Round tube 20-90 Square tube 20-70 |

|

Use TCT superhard circular saw blade(mm) |

Diameter 360mm thickness 2.25mm |

|

Pin hole and aperture(mm) |

4xdia11xPCD90xdia40 |

|

Power of Spindle motor(kw) |

11(4p) |

|

Rotate of spindle speed(rpm) |

50-160 |

|

Cut feed way |

AC motor+ball screw/roller linear guide |

|

Main clamp way |

Hydraulic type/vertical and horizontal clamping of each group |

|

Saw blade debris removal device |

Passive round wire brush/active round wire brush |

|

Gear gap compensation device |

Through-type magnetic powder brake |

|

Feeding drive mode |

AC servo motor+ball screw |

|

Feeding clamping way |

Hydraulic clamped |

|

The material front end removes the length |

10-99mm (optional) |

|

Material back-end material length |

70mm+α(α is not enough to cut the length of a workpiece) |

|

Single feed cut length |

6-780(mm) |

|

Allow the length of the material |

2000-6000(mm) |

|

Supply mode |

Preload/hydraulic lifting |

|

Hydraulic pump type |

Variable plunger mercury |

|

Hydraulic system rated pressure |

7 MPa |

|

The power of Hydraulic drive system |

3.75kw |

|

Hydraulic oil capacity |

90L |

|

Weight of machine (machine+rack) |

5000kg |

|

Size of the machine |

7000x2710x1689mm |

|

Saw blade deflection shock device |

Tungsten carbide parallel block |

|

Dispenser |

Pneumatic/reciprocating |

|

Manual concentration of grease lubrication system |

Quantitative forced to oil |

|

Tool micro-lubricating system |

Quasi-dry intermittent to oil |

|

Chip conveyor |

Chain plate type/continuous or intermittent operation |

|

Working lamp |

LED waterproof and dustproof |

|

Electric control box heat exchanger |

Enclosed high efficiency heat exchange system |

|

Centrifugal oil mist recovery machine |

Multi-level filtering,energy saving and environmental protection |

|

Cluster feeding device |

The whole bundle of material,long material cutting preferred |

|

The third clamp |

The length of material 20+α(α is not enough to cut the length of a workpiece) |

|

Long material to undertake device(discharge device) |

A variety of ways flexible choice,can be equipped with robots expected code material |

1 This machine is a fully automatic high speed metal circular saw machine, it specially designed for cutting round solid rods and square solid rods,according to customer’s requirements for high speed cutting and high precision cutting. Saw cutting off speed:9-10seconds sawing off diameter 90mm round solid rods. cut section roughness :3.2, work accuracy: saw blade flange end/radial beat ≤ 0.02, saw section with workpiece axial line vertical degree: ≤ 0.2 / 100, saw blade repeated positioning accuracy: ≤ ± 0.05, The main parts of Naisite high-speed metal circular saw machine are imported from Japan.

2 Whole fuselage structure adopt QT500 spheroidal graphite cast iron,guarantee rigidity of the fuselage structure.