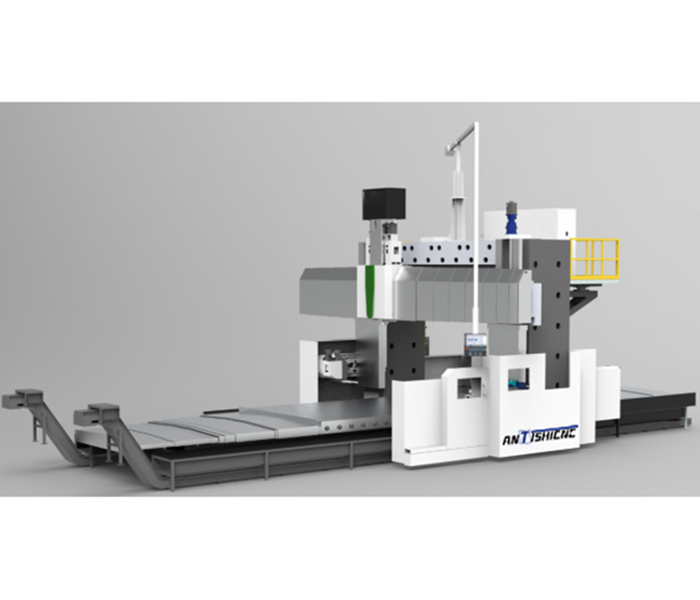

CNC gantry boring and milling machine is an advanced CNC machine tool for machining with a gantry frame structure, high stability and rigidity, and the ability to withstand large cutting forces.

Its processing characteristics are mainly manifested as follows:

1.High-precision processing: CNC gantry boring and milling machines use high-precision transmission components, such as ball screws, linear guides, etc., as well as advanced measurement feedback devices, such as grating rulers, encoders, etc., which can achieve precise position control and motion trajectory control. The processing accuracy can reach micron level or even higher, which can meet the needs of industries with extremely high precision requirements such as aerospace and precision molds.

2.High-efficiency processing: With high cutting speed and feed speed, it can remove a large amount of material in a short time and improve processing efficiency. At the same time, functions such as multi-axis linkage and automatic tool change reduce the number of workpiece clamping times and auxiliary processing time, further improving the overall processing efficiency, and are suitable for mass production and processing of large parts.

3.Complex shape processing capability: With the multi-axis linkage function, various parts with complex surfaces, contours and cavities can be processed, such as impellers, blades, mold cavities, etc., which can meet the needs of modern manufacturing industry for complex parts processing.

CNC gantry boring and milling machines are mainly divided into moving beam CNC gantry boring and milling machines and fixed beam CNC gantry boring and milling machines. Their main differences are as follows:

| Features | Moving beam CNC gantry boring and milling machine | Fixed beam CNC gantry boring and milling machine |

| Structural design | The crossbeam can move up and down on the column to meet the processing requirements of workpieces of different heights. The workbench is generally fixed, and the gantry frame part is movable. The processing position can be adjusted by raising and lowering the crossbeam and moving the column on the bed. | The crossbeam is fixed on the column and cannot move up and down. Usually the workbench can move, driving the workpiece to be processed under the crossbeam, and the processing operation is completed by the longitudinal and lateral movement of the workbench and the movement of the slide and other components. |

| Processing accuracy | Since the beams and columns need to move, the weight and inertia of the moving parts are relatively large, and certain vibrations and errors may occur during the movement. The processing accuracy is relatively low, which is suitable for processing large and heavy workpieces that do not require extremely high accuracy. | The crossbeam is fixed, the overall rigidity and stability of the machine tool are better, which can better ensure the accuracy of the processing process, especially when processing parts with high precision requirements, such as some parts processing in the fields of aerospace, precision molds, etc. |

| Processing range | The crossbeam height can be adjusted flexibly, which is suitable for processing workpieces with large height changes. It has strong adaptability to the height of the workpiece and can process super-large and heavy workpieces without being restricted by the load-bearing capacity of the workbench. | It is more suitable for machining workpieces of various shapes and complexities with relatively fixed height but within the range of worktable size. For some large planes, cavities, etc., if the workpiece height is within the design range of the machine tool, the fixed beam type can also complete the work well. |

| Processing efficiency | When processing some workpieces that need to adjust the processing height frequently, the movable beam type can quickly adjust the crossbeam position, reducing the time of re-clamping and adjusting the tooling, and improving the processing efficiency. However, if a large number of workpieces of the same height are repeatedly processed, the advantage of the movable crossbeam is not obvious. | Due to the high stability and positioning accuracy of the worktable movement, the fixed beam type can achieve efficient processing through fast worktable movement and precise positioning during mass production and high-precision processing. |

| Manufacturing Cost | The moving beam structure is relatively complex and requires a reliable beam lifting drive system and high-precision guide rails to ensure the accuracy and stability of the beam movement. The manufacturing cost is relatively high. | The fixed beam structure is relatively simple, mainly the movement of the workbench and the movement of the ram and other components, and the manufacturing cost is relatively low |

| Applicable scenarios | It is widely used in shipbuilding, large steel structure processing, large mold rough processing and other fields. | It is more commonly used in industries with high precision requirements such as aerospace, precision machinery manufacturing, and mold finishing. |

If you have similar needs, please contact Shanghai ANTISHICNC: contact@antsmachine.com.

We not only have CNC gantry boring and milling machines with movable beams and fixed beams, but also ordinary boring and milling machines and CNC boring and milling machines. Our technical team will definitely be able to match you with the most suitable technical solution.