In order to choosing the right vertical machining centre, it is often necessary to consider the need to configure the fourth axis, the fourth axis of the machining centre is mainly for the expansion of machining capacity, improve machining accuracy and efficiency. So how to choose the right 4-axis rotary table to use? This article gives you a detailed introduction.

| Size and shape of work-pieces to be processed | The shape and size of the work-piece is a key consideration when selecting a fourth axis for a machining centre. If you are machining a round bar type work-piece, you will need to purchase a three-jaw chuck and a thimble tail-stock, and be careful that the outside diameter of the chuck is not larger than the diameter of the disc.

When it is necessary to process shaped work-pieces, and more than two at a time, it is necessary to purchase additional disc tail-stock. For larger sizes of shaped work-pieces, it is also necessary to consider whether the radius of rotation and stroke of the fourth axis can meet the processing requirements. Generally speaking, it is more appropriate to choose the diameter of the fourth axis slightly larger than the diameter of the work-piece. |

| Weight of the work-piece | Calculate the total weight of the machined work-piece plus fixtures, etc., which should be less than the larger load capacity of the selected fourth axis. Note that the maximum load capacity of the rotary table with a tail-stock is twice as much as without a tail-stock. |

| Material of the work-piece | If the work-pieces to be machined are made of copper and aluminium, which are relatively soft and have low cutting forces, a pneumatic locking fourth axis is usually sufficient. This provides sufficient clamping force and is more economical.

However, if the work-piece is made of harder materials such as cast iron and steel, with higher cutting forces, a hydraulically clamped fourth axis is required. Hydraulic clamping provides a stronger, more stable clamping force, ensuring that the fourth axis can hold the work-piece securely during machining, preventing displacement or precision deviations caused by excessive cutting forces. For example, when machining automotive engine blocks, which are made of cast iron, a hydraulically locked fourth axis must be used to ensure machining accuracy and stability. |

| Precision requirements | The accuracy of the fourth axis rotary table is directly related to the machining effect and product quality. It is important to pay attention to its indexes such as rotary accuracy, positioning accuracy and repetitive positioning accuracy. There may be differences in the accuracy of the fourth axis produced by different manufacturers, so careful comparison is required. For machining tasks that require high precision, choose a fourth axis whose precision can reach micron level or even higher. At the same time, attention should be paid to accuracy retention, i.e. the fourth axis is able to maintain a high level of accuracy even after a long period of use. In addition, it is also necessary to consider the balance between accuracy and cost to ensure that the product with the best price/performance ratio is selected under the premise of meeting the demand for machining accuracy. |

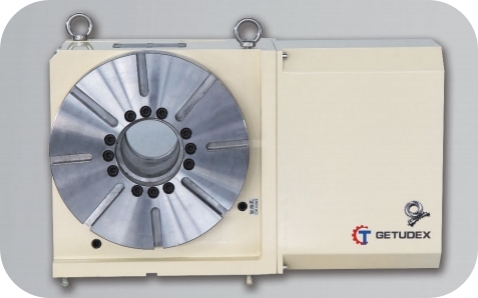

| Brand and quality | Brand is also a key consideration when choosing the fourth axis of a machining centre. Some well-known brands usually have advantages in technology development, production process and quality control.

For example, some brands from Taiwan, China have accumulated extensive experience in the manufacturing of fourth axes, and their products excel in terms of precision, stability and durability. However, fourth axes from different brands may differ in price, performance and after-sales service. When choosing a brand, you should not only consider its market reputation and user evaluation, but also understand the technical characteristics and applicable range of its products. At the same time, you should consider your own processing needs and budget to choose the most suitable brand and model. |

In summary, choosing the fourth axis of a machining centre requires comprehensive consideration of a number of factors such as size and shape, load bearing, material, precision requirements, brand and quality. Only a comprehensive weighing of these factors can choose the most suitable for their own processing needs of the fourth axis, improve processing efficiency and quality.

Shanghai ANTISHICNC is a professional manufacturer of CNC milling machines, we have a wealth of production and machining experience, we can match your products with the right machining centre and the right fourth axis, can provide you with professional technical support! If you have milling machine production needs.Please send your inquiry or questions to contact@antsmachine.com for instant feedback.

Tags : Milling machine,VMC,machine center, fourth axis machine center,CNC milling machine.