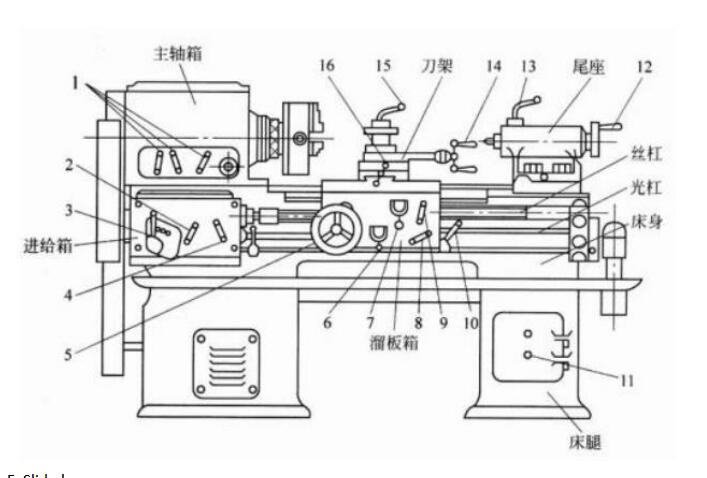

1. Ordinary lathe bed

Bed: It is the basic part of the lathe, which is used to support and install the various parts of the lathe to ensure their relative position, such as the bedside box, feed box, slide box, etc. The bed has sufficient rigidity and strength, and the surface accuracy of the bed is very high to ensure the correct relative position between the components.

There are four parallel guide rails on the bed for correct movement of the carriage and tailstock relative to the headstock. In order to maintain the surface accuracy of the bed, attention should be paid to maintenance during the operation of the lathe.

2. Lathe Machine Headbox

The headstock is also called the headstock, which supports and drives the main shaft to drive the workpiece for main rotation. The box is equipped with gears, shafts, etc. to form a variable speed transmission mechanism. Changing the handle position of the spindle box can make the spindle get a variety of speeds.

The C6132 lathe has only one-stage speed change in the main shaft box, and its main shaft speed change mechanism is placed in a separate gearbox far away from the main shaft to reduce the impact of vibration and heat generated by the transmission parts in the gearbox on the main shaft.

3. Lathe Machine Tool Feed Box

The feed box is also called the tool feed box, which is equipped with a variable-speed gear for feeding movement, which can adjust the feed amount and pitch, and transmit the movement to the polished rod or screw rod.

4. Exchange gearbox

The exchange gear box transfers the rotation of the headstock to the feed box. By replacing the gears in the box and matching the speed change mechanism in the feed box, the feed motion of turning various pitch threads can be obtained, and the demand for different longitudinal and transverse feeds during turning can be met.

5. Slide box

The carriage box accepts the movement transmitted by the light rod or the lead screw to drive the bed saddle, the middle and small slide plate and the tool post to realize the longitudinal and lateral feed movement of the turning tool. It is also equipped with some handles and buttons, which can easily operate the lathe to guide the selection

6. Tool holder

The structure of the tool holder is a sliding plate, a small sliding plate, a saddle and a tool holder body, which are used to install the turning tool and drive the turning tool to move longitudinally, horizontally or diagonally.

7. Tailstock

The tailstock is installed on the bed rail and moves longitudinally along this rail to adjust its working position. The tailstock is mainly used to install the rear center to support longer workpieces. Drills, reamers, etc. can also be installed for hole processing.

8. Cooling device

The cooling device mainly uses a cooling water pump to pressurize the cutting fluid in the water tank and spray it to the cutting area, which is used to reduce the cutting temperature, wash away the chips, and lubricate the processed surface, thereby improving the service life of the tool and the surface processing quality of the workpiece.

9. bed legs

The front and rear legs 10 and 5 are respectively connected to the lower part of the front and rear ends of the bed to support various parts installed on the bed. At the same time, the whole lathe is fixed on the work site through anchor bolts and adjustment pads, and the bed is adjusted to a horizontal state.