Recently, Shanghai ANTS received an inquiry from a Latvian customer. Their company manufactures cutting-edge heat exchangers and high-performance thermal superconductors, such as heat pipes and thermal loops, for electronic equipment cooling and gas thermal compression. The customer requires a CNC pipe bending machine to process small stainless steel tubes (material: AISI 316L) with the following dimensions: outer diameter: 4-12 mm (larger sizes are also acceptable), bending radius: ≥20 mm (slightly larger is also acceptable), and tube length: up to 2 meters. Based on the customer’s parameters, we recommended our best-selling product: the CNC2503RES pipe bending machine. This machine has a maximum bending capacity of 25*2.0 mm for carbon steel, 25*3.0 mm for stainless steel, and 20*3.0 mm for square metal tubes; it fully meets the customer’s needs. The customer liked it and sent us a sample order, which is currently in progress. The sample will be sent to the customer for confirmation after completion.

The ANTS CNC2503RES pipe bending machine is a hybrid electric servo pipe bending machine. It features three electric servo drives: Y (feeding), B (pipe rotation), and C (bending).

These three electric servo drives, combined with a precision carriage servo rotation, achieve a bending accuracy of ±0.03° and a feeding accuracy of ±0.03mm. The use of electric servo drives avoids the accuracy issues of ordinary pipe bending machines, which are affected by oil temperature, making it suitable for high-load, high-volume production.

This three-dimensional CNC pipe bending machine boasts a high-rigidity mechanical structure design and precision manufacturing process based on dynamic mechanics principles. While maintaining structural strength, the simple bending handle and bending head design provides maximum bending space, minimizing machine interference. Equipped with an automated programmable control system, it can easily meet the dual requirements of mass production and high precision for various types of steel pipe bending tasks with high complexity.

The relevant parameters of the CNC2503RES pipe bending machine are as follows:

| Specifications | Units | CNC2503RES |

| Max.bending capacity | mm | Carbon steel

25*2.0 |

| Max.bending capacity | mm | Stainless steel

25*3.0 |

| Max.bending capacity | mm | Metal square tube

20*3.0 |

| Bending radius range | mm | Round tube: 15-120 |

| Bending radius range | mm | Square tube: 20-100 |

| Max.pipe diameter for reciprocating feeding | Mm | 25 |

| Bending angle range | Degree | 190 |

| Max.effective distance for core penetration | mm | 2000(Can be customized and extended as needed) |

| Machine working height | mm | 1100 |

| Mold centerline height | mm | 20-150 |

| Bending servo motor | W | 2000 |

| Bending movement speed | Deg/sec | 170 |

| Bending accuracy | Degree | ±0.01 |

| Feeding servo motor | W | 750 |

| Feeding movement speed | Mm/sec | 500-1000 |

| Feeding accuracy | mm | ±0.01 |

| Turn servo motor | W | 400 |

| Turn movement speed | Deg/sec | 360 |

| Turn rotation accuracy | Degree | ±0.01 |

| Auxiliary push movement speed | Mm/sec | 120 |

| Core penetration movement speed | Mm/sec | 80 |

| Hydraulic motor | KW | 3 |

| System Max.pressure | Kgf/cm2 | 100 |

| Preset pressure | Kgf/cm2 | 70 |

| Total power | KW | 8 |

| Machine length | Mm | 3700 |

| Machine width | Mm | 1000 |

| Machine height | Mm | 1350 |

| Machine weight | KG | About 1550 |

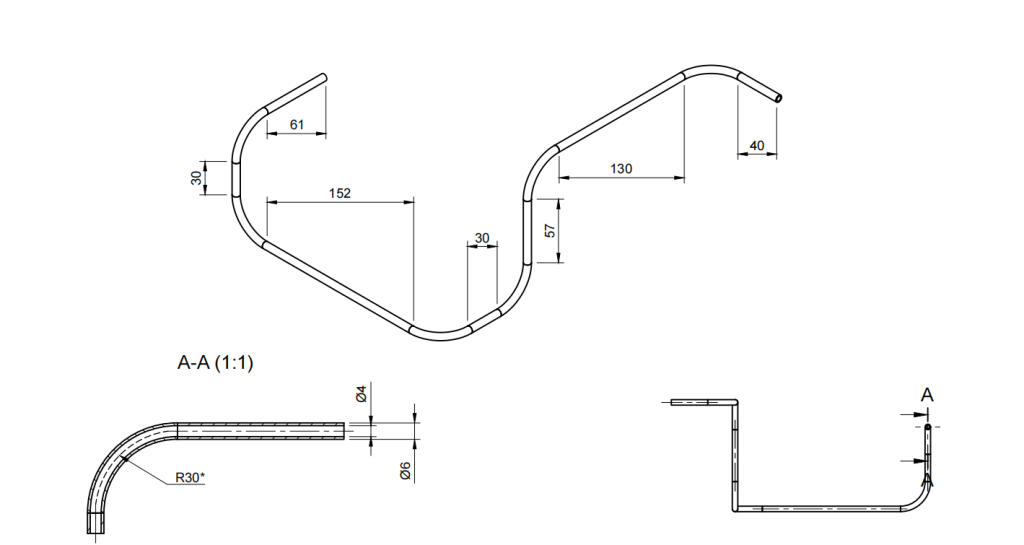

The customer’s workpiece drawing is as follows:

ANTS provided a professional response to the customer’s requirements and ultimately quoted a CNC2503 pipe bending machine, which was well received by the customer. If you have similar needs, please feel free to contact Shanghai ANTS: contact@antsmachine.com. We offer not only fully automatic pipe bending machines, but also semi-automatic pipe bending machines, pipe cutting machines, pipe end forming machines, and other products. Our technical team will definitely be able to match the most suitable technical solution for your needs.

Keywords: Hybrid electric servo pipe bending machine, all-electric pipe bending machine, pipe cutting machine, pipe end forming machine, etc.