In the automotive manufacturing industry, metal high-speed intelligent circular saw machines are currently widely used. Most of the spare parts and castings of automobiles are made of metal materials. By selecting circular saw blades of different specifications and properties and combining them with saw machines, different materials can be easily cut. This equipment can realize an automated and efficient cutting process and can provide necessary help for the automotive manufacturing industry.

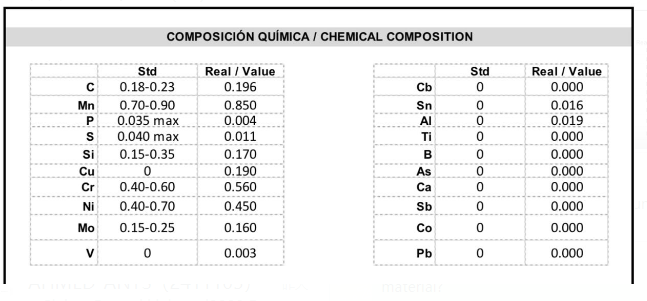

Recently, Shanghai Antis Machinery Equipment Co., Ltd. received an inquiry from a Mexican customer. The customer is engaged in the manufacture of auto parts, retail and wholesale of auto parts, and is committed to supplying various German and Swedish auto parts, including Mercedes-Benz, BMW, Volkswagen (Volkswagen), Audi, Volvo and Saab. There are also a large number of Mercedes-Benz, BMW and Volvo auto parts in stock. It is understood that the customer mainly cuts 96 mm in diameter (steel SAE 8620 or EN362) and 87 mm in diameter (steel BH 1518 or ASTM A29), and will be put into production in large quantities in January 2025.

During the communication process, the customer said that he would come to China in October to test the machine at our factory and sent us samples in advance.

| Customer workpiece display | ||

|

|

|

| Material composition of customer workpieces | ||

|

||

According to the customer’s workpiece material and workpiece size, we recommended our HY-100NC and HY-85NC high-speed circular saw machines to the customer.

| HY-85NC/HY-100NC technical parameters | ||

| Technical Specification| Model | HY-85NC | HY-100NC |

| Cutting Capacity for Round bar(mm) ● | 10-85 | 30-100 |

| Cutting Capacity forSquare bar(mm) ■ | 10~65 | 30~76 |

| Cutting Capacity forRound pipe (mm)○ | 10-85 | 30-100 |

| Cutting Capacity for square pipe (mm)□ | 10-65 | 30~76 |

| TCT Super hard circular saw blade (mm) | 315 X 2.25T | 360 X 2.6T |

| Pin hole and aperture(mm) | 4xφ11 XPCD63X φ32 | 4xφ11 XPCD90X φ40 |

| Spindle motor(kw) | 9.5(4P) | 11(4P) |

| Spindle speed(rpm) | 20-180 | 20-120 |

| Saw head feeding moethod | AC servo motor+ball screw(30° tilt feeding) | AC servo motor+ball screw(Pivot type feeding) |

| Main clamping vises | Hydraulic, one set of vertical and horizontal clamping | Hydraulic, one set of vertical and horizontal clamping |

| Chips cleaning device | Passive wire brush/power wire brush(optional) | Passive wire brush/power wire brush(optional) |

| Gear backlash compensation device | Through shaft type magnetic powder brake | Through shaft type magnetic powder brake |

| Workpiece feeding drive method | AC servo motor+ball screw | AC servo motor+ball screw |

| Feeding vise clamping method | Hydraulic, horizontal clamping | Hydraulic, horizontal clamping |

| Workpiece front end removal length (This function can be closed) | 10~99mm | 10~99mm |

| Workpiece final remnant length (mm) | 70+α(α is smaller than the setup cutting length) | 75+α(α is smaller than the setup cutting length) |

| Single feeding length range (mm) | 6-800 | 10-680 |

| Automatic workpiece feeding length to be loaded (mm) | 3000-6000 | 3000-6000 |

| Automatic workpiece feeding method | Pr-arranged type|hydraulic lift | Pr-arranged type|hydraulic lift |

| Hydraulic motor(kw) | 2.25(4P) | 2.25(4P) |

| Rated pressure of hydraulic system(MPa) | 4.5~7 | 4.5~7 |

| Hydraulic tank capacity(L) | 120 | 110 |

| Cooling fluid device motor (kw) | 0.19(2P) | 0.19(2P) |

| Weight(host machine+roller table) (kg) | 4500 | 3900 |

| Machine Size(LXW) (mm) | 6910X3000 | 6500X2760 |

Customer on-site test machine display

|

|

|

| Circular saw machine display | Cutting display | Finished product display |

|

|

|

| Feeding position | Circular saw machine rack | Machine packaging |

Customers visit the site to test the machine

|

|

With our careful help and the customer’s active cooperation, the customer successfully found a fully automatic high-speed circular saw machine suitable for him and upgraded his production capacity.

If you are also in the automotive manufacturing industry,Welcome to consult Shanghai ANTISHICNC Team. We are a senior supplier of band saws, with rich experience in manufacturing and utilizing machinery and equipment, and can provide you with professional technical support.

Please send e-mail to: contact@antsmachine.com.