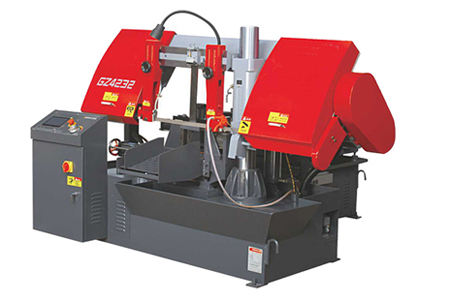

The CNC sawing machine is driven by the driving wheel and the driven wheel to rotate the saw blade, and the cutting direction of the saw blade is controlled by the guide rail manipulator. After adjusting the rotation bearing, the band saw blade is straightened and straightened by the sweeper to sweep away the sawing. The guide rail manipulator is supported by the piston rod of the hydraulic cylinder and falls into the sawing material. The band sawing machine is equipped with a manual or hydraulic cylinder clamping and locking mechanism, and its hydraulic operation valve switch. So, what are the measures to reduce the noise of the band sawing machine?

The following summary is for reference only:

When the bimetal band saw blade rotates at high speed during cutting, the noise source can be divided into two stages.

One is the power noise of the sawing machine. The rotating band sawing machine interacts with the surrounding air, causing pressure pulsation and then forming eddy currents (also known as: Foucault current) at the edge of the saw blade, which then constitutes noise. CNC sawing machines use circular saw blades, saw bands or saw blades as tools to saw metal round materials, square materials, tube materials and profiles. The machining accuracy of the sawing machine is usually not very high, and it is mostly used in the material preparation workshop to cut off various types of bars, pipes and other profiles.

On the other hand, there is the mechanical noise of the sawing machine, the mechanical noise caused by the friction and vibration between the sawing machine and the metal material. During the working process of the sawing machine, the size of the pollution depends on the shape and hardness of the material. In order to better reduce noise pollution, muffler grooves can be opened on the band saw. Increase the elasticity of the machine, reduce the tension and then reduce the vibration noise. Adding a rubber pad to the chuck can reduce the transmission of vibration to achieve the effect of reducing noise. When it is important, the sound insulation cover can be closed. The structure of the sawing machine is varied, and the noise during the sawing process is transmitted through the air. After sound insulation, sound absorption, noise reduction and other skills, the entire sawing machine is closed to achieve the purpose of noise reduction. The cover of the sawing machine is made of a steel plate with a thickness of about 2mm, and a special coating is applied to the inner side of the steel plate to absorb sound waves to reduce noise. Install a muffler at the vent on the cover. If you need a better effect, you need to use a double-layer metal plate structure, and the metal plates are filled with sound-absorbing materials.

How to reduce the mechanical noise of the sawing machine

The technical department applies sound insulation and sound absorption technology to the band sawing machine, reasonably reduces noise pollution, solves the problem of noise pollution in the workshop, improves the working environment of the company, protects the health of workers to a great extent, and responds to the road of green production.

CNC sawing machines use circular saw blades, saw bands or saw blades as tools to saw metal round materials, square materials, tube materials and profiles. The machining accuracy of the sawing machine is usually not very high, and it is mostly used in the material preparation workshop to cut off various types of bars, pipes and other profiles.

The above is about the method introduced by the sawing machine manufacturer today on how to reduce the mechanical noise of the sawing machine. If you want to know more about the sawing machine or want to consult the price of the sawing machine, please contact us.