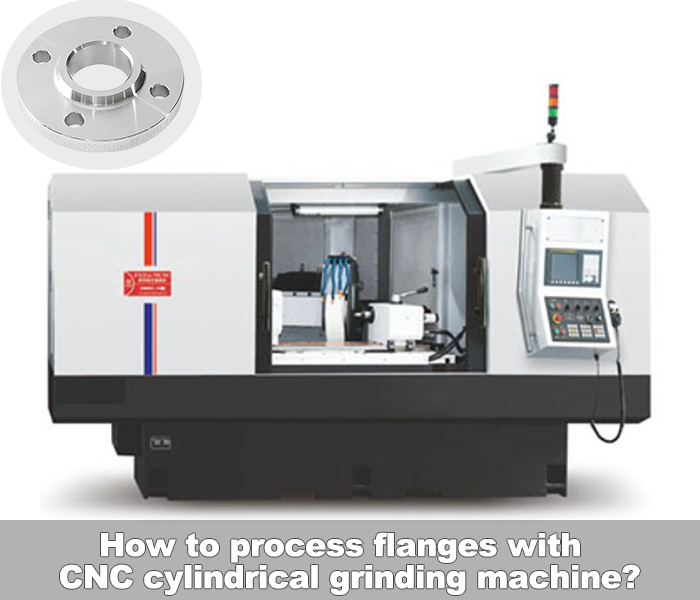

Flanges are important parts for connecting mechanical equipment and are diffusely used in many areas such as machinery production, petrochemicals, electric power, and ships.Their processing accuracy is directly related to the safety and stability of equipment operation.In the past, traditional cylindrical grinding machines had large processing errors and unsatisfactory surface roughness when processing high-precision flanges, making it difficult to meet the increasingly stringent standards of the current industry.

Shanghai ANTISHICNC Company has made many optimizations to the traditional cylindrical grinder. By upgrading the CNC system of the cylindrical grinding machine, precise control of the flange grinding process is achieved, with a machining accuracy of ±0.001mm, a roundness error within 0.003mm, and a roughness Ra value of 0.25μm. In actual processing, this technology can ensure the coaxiality of the outer circle and inner hole of the flange, effectively improving the sealing and stability of the flange during assembly. While improving the accuracy, the processing efficiency of the cylindrical grinder has also been greatly improved.

|

|

The FX32A-35CNC cylindrical grinding machine is equipped with a high-speed grinding wheel and an efficient cooling system. The grinding wheel linear speed can reach up to 45m/s. Under the premise of ensuring processing quality, the grinding efficiency is increased by 20%. At the same time, the application of automatic loading and unloading devices reduces manual intervention and further shortens the processing cycle. Taking the processing of carbon steel flanges with a diameter of 300mm and a thickness of 50mm as an example, the traditional processing method can only complete 3-4 pieces per hour, while the improved cylindrical grinder can process 8-10 pieces per hour, and the production efficiency is significantly improved.

The following is an introduction to the FX32A-35CNC cylindrical grinding machine:

| Items | Unit | FX32A-35CNC | |

| Processing Capability | Worktable maximum rotating diameter | mm | 320 |

| The longest distance between two top centers | mm | 500 | |

| Effective grinding length | mm | 350 | |

| Maximum grinding diameter | mm | 320 | |

| Maximum load between two top centers | Kg | 150 | |

| Grinding wheel size: diameter × width × aperture | mm | 510×50×203.2 | |

| Wheel speed | rpm | 1670 | |

| Maximum line speed | m/s | 45 | |

|

|||

Shanghai ANTISHICNC Company will continue to optimize the processing technology of cylindrical grinders, increase R&D investment, explore the application of intelligent and automated processing technology in cylinder manufacturing, and strive to provide global customers with better quality and more efficient flange solutions.