Dressing is a grinding operation, a necessary link, is often overlooked by the importance of the link. This time I would like to take this article to talk to you, dressing for grinding in the end what kind of important impact!

Why dress grinding wheels?

During the grinding process, the condition of the grinding wheel directly affects the grinding results. Changes in the condition of the grinding wheel, such as changes in cutting force and changes in the shape of the wheel, will have an impact on the yield and reproducibility of the finished product.

Generally speaking, the most commonly encountered change is that the grinding wheel ‘does not cut’, meaning that the grinding wheel has lost its cutting force; and there are two main reasons for the grinding wheel to lose its cutting force:

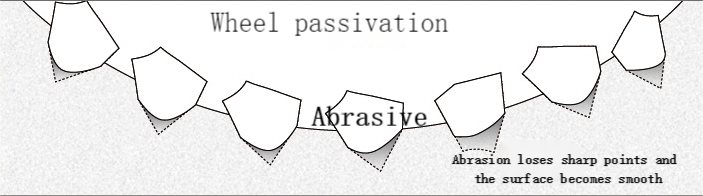

The first is that the abrasive grains are gradually rounded off during the grinding and squeezing process, which we call ‘passivation’. At this time, the self-sharpening ability of the grinding wheel does not play a role at the right time, which will lead to a reduction in cutting power, unable to effectively play the role of grinding.

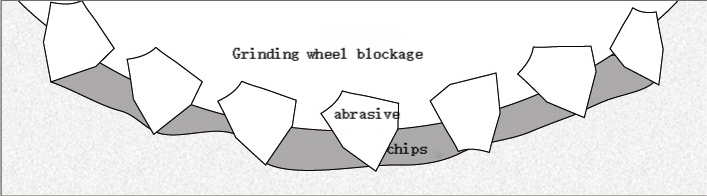

The second is due to the grinding process, which results in the production of debris. This is especially true for materials that are sticky. If the air holes of the grinding wheel are not large enough or the porosity is low, the debris will easily fill in the air holes and cause ‘clogging’. As a result, the grinding wheel becomes a non-serrated flat surface and loses cutting power.

Another condition that needs to be repaired is ‘unevenness of the grinding surface of the wheel’: the grinding wheel wears out during the course of use. Such wear causes the grinding wheel to lose its roundness and the grinding surface to become uneven. This condition causes problems such as deflection during grinding and reduced grinding efficiency.

When the grinding wheel is in such an unstable state, it must be dressed to restore cutting power or true roundness to the wheel. However, because the grinding wheel rotates at high speeds during the process, it is often impossible to see with the naked eye whether the wheel has lost cutting power or is uneven.

However, in the case of loss of cutting power, many abrasive phenomena will be generated, and if these phenomena are generated, it is possible to estimate whether or not the grinding wheel needs to be dressed.

When should I dress the grinding wheel?

As mentioned above, the lack of cutting power due to passivation and clogging, and the unevenness caused by abrasion will be directly reflected in the grinding results; therefore, when the following conditions occur during grinding, it is time to dress the grinding wheel!

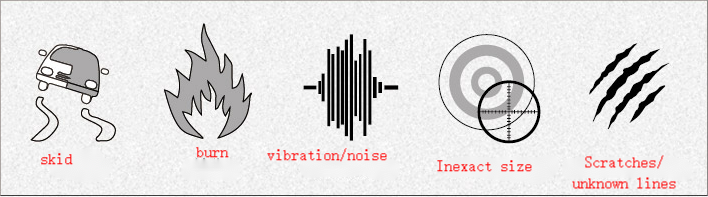

★ Slippage: The grinding wheel becomes a flat surface due to the loss of cutting power, just like the tread of a tyre being smoothed out, losing friction, in which case it is easy to produce the phenomenon of slippage.

★ Burn: caused by burns is the most serious loss of cutting power, this situation most often occurs due to the blockage of air holes caused by the loss of cutting power of the situation, need to be repaired immediately.

★ Vibration / noise: this situation, is another phenomenon in addition to slippage, because there is no friction, the grinding wheel surface can not effectively contact with the workpiece. In addition, if the grinding wheel roundness is lost and unevenness occurs, it will also produce vibration and even noise.

★ Dimensional imprecision: Loss of dimensional accuracy indicates that the grinding wheel has lost its cutting power to a serious degree and needs to be repaired immediately.

★ Scratches on the surface of the workpiece or abnormal grinding pattern: If there are scratches on the surface of the workpiece, it means that the self-sharpening ability of the grinding wheel has begun to decline, and abnormal grinding pattern usually indicates that the performance of the grinding wheel has begun to have problems.

When the above conditions occur, it is already time to repair the grinding wheel. Neglecting to do so can cause great damage to the workpiece and affect the efficiency of the entire process. The best situation is to repair the grinding wheel when it is about to appear the above conditions, in order to maintain a good yield of the workpiece.

Of course, it is not possible to dress the grinding wheel all day long, because the process of dressing will still bring some related costs, which is also a part we need to pay attention to when dressing the grinding wheel.

The Cost of Trimming

Although the cost of a single repair may seem small, there are intangible costs that we often overlook. If all these costs are added up, they can add up to a considerable amount in the long run. Therefore, we should also have a certain degree of understanding of the possible costs of refurbishment.

Direct Costs

Grinding wheel wear: This is the most direct and obvious cost.

If the grinding wheel itself is not expensive, there may not be much cost consumption, but if it is a high-priced grinding wheel, the cost of reconditioning can be very significant.

The industry can calculate the cost by recording the average usage rate of a grinding wheel or the average dressing rate.

Wear and tear of the dresser: This is also a cost that can be directly associated with the cost of the cost and calculation method, and the cost of grinding wheel wear and tear is not far from the cost.

Indirect Costs

★ Dressing time: The time it takes to dress a grinding wheel is a cost that clearly affects efficiency.

The longer it takes to dress the wheel, the longer the production line or machine downtime will be, and if the process can be completed in a short period of time, the effect of dressing time will be more significant.

★ Manpower costs: grinding wheel dressing needs personnel to perform, during this period, the personnel could have been engaged in other work matters. But because of the grinding wheel needs to be repaired, and become only the first implementation of this project, which affects the efficiency of the whole.

★Workpiece yield: If the grinding wheel needs to be dressed frequently, the yield of the workpiece may decrease.

Because the grinding wheel loses its cutting force to a large extent, the dimensional accuracy or surface roughness of the workpieces processed by the grinding wheel that has just been dressed and the grinding wheel that needs to be dressed critically may be very different.

The decrease in yield rate also means an increase in the number of workpieces that need to be re-machined, resulting in a significant reduction in cost and efficiency.

Cost Reduction Methods

The costs mentioned above interact with each other. For example, although grinding wheels need to be dressed from time to time, the dressing time can be greatly reduced if the dresser or personnel have good dressing ability. So the most effective way is to minimise the number of times and time needed for dressing, the relevant items are as follows:

★ Grinding wheel: the quality of the grinding wheel is the most direct impact on the frequency of dressing factors, a high self-sharpening and not easy to block, you can significantly reduce the frequency of dressing, but the relative cost of the grinding wheel may be more expensive.

Low-cost grinding wheels, although the cost of grinding is lower, but if you need to always dress, long time down the cost caused by the wheel may be far greater than the high quality and do not need to dress from time to time.

★ Dresser: The dresser affects both dressing frequency and dressing time. A good dresser can make the dressing wheel to achieve the best condition to reduce the frequency of dressing; or because of easy operation, can quickly dress the wheel, can effectively reduce the dressing time to improve processing efficiency.

★Staff quality: Wheel dressing is a process that requires experience and skills, very much dependent on the feeling. If you don’t have enough experience, the dressing time will be longer or the quality of the dressing is not good enough, which will lead to the grinding wheel needing to be repaired from time to time or the yield of the workpiece will be reduced.

Understand and keep records

The grinding wheel grinding ability is from good to bad, and then from bad to good a kind of cycle, dressing will determine the frequency of this cycle. How to decide the timing of dressing affects the efficiency of the process and the yield of the finished product. The best state is to understand and record each production line grinding wheel, its dressing time, dressing interval and the most effective dressing method.

Eliminating grinding problems before they occur and avoiding unnecessary waste is the best way to dress and keep the wheels in optimum condition.

ANTISHICNC has many years of experience in metal grinding and wheel dressing, if you have a need for a grinding machine or wheel dresser please contact us.

Website :www.antsmachine.com

Email :contact@antsmachine.com