A horizontal machining center refers to a machining center with a horizontal spindle, usually with an automatic indexing rotary table, which generally has 3 to 5 motion coordinates. It is common to have three linear motion coordinates plus one rotary motion coordinate. After the workpiece is clamped once, the processing of the other four surfaces except the mounting surface and the top surface is completed. It is most suitable for adding box-type parts.

Compared with the vertical machining center, the vertical machining center refers to the machining center with the main shaft in a vertical state. Its structure is mostly fixed columns, the workbench is rectangular, and there is no indexing and rotating function. It is suitable for processing discs, sleeves, and plate parts. . The vertical machining center generally has three linear motion coordinate axes, and a rotary table that rotates along the horizontal axis can be installed on the workbench to process spiral parts;

The horizontal machining center has the characteristics of high precision, strong rigidity, fast speed and large torque. Horizontal machine tools are suitable for high-precision complex boxes and high-efficiency processing of shell parts. It is also suitable for machining parts of axle housing, differential housing, pump body and valve body type. Comparing the horizontal machining center with the vertical machining center, the horizontal machining center is easy to remove chips during machining, which is beneficial to machining, but the structure is complex. The price is higher.

The workbench is different: the workbench of the horizontal machining center is only designed to move in the X or Y direction. The form of the workbench is generally a rotary workbench with dot matrix screw holes. It is relatively easy to choose an exchangeable double workbench. The workbench of the vertical machining center is a T-slot workbench with a cross slide structure. There are two sets of motion mechanisms responsible for the movement in the vertical direction. The workbench for X-direction feed is covered on the guide rail responsible for Y-direction feed;

Linear axis positioning accuracy and repeatability accuracy of horizontal machining centers. Table angle, positioning accuracy and repeat positioning accuracy. Two-axis linkage interpolation milling circle accuracy and U-turn boring accuracy. The numerical control compensation technology is applied to improve the machining accuracy of the horizontal machining center.

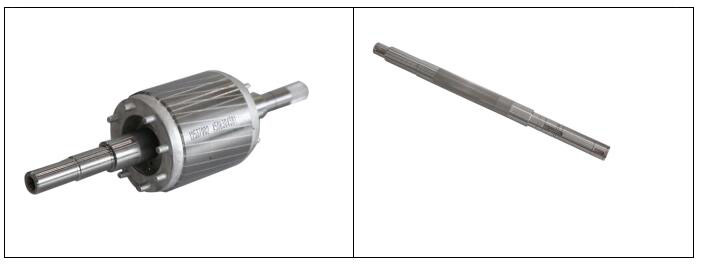

The following common products are all processed by horizontal machining centers

Example: Motor rotor (shaft machining): Also a rotating part in a motor. The motor consists of two parts, the rotor and the stator, which are used to realize the conversion of electrical energy and mechanical energy and mechanical energy and electrical energy. Motor rotors are divided into motor rotors and generator rotors, which are important auto parts;

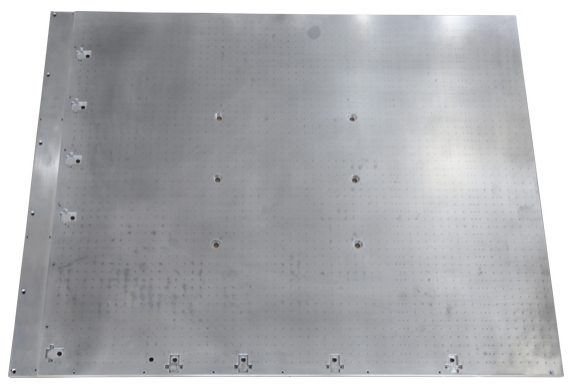

Commercial Vehicle Chassis Suspension

This is the supporting part of the commercial vehicle air suspension, which is processed by a horizontal machining center. The end customers include Beiben, Foton, Hino and other top commercial vehicle manufacturers. After the workpiece is once clamped on the machining center, the digital control system can control the machine tool to automatically select and replace the tool according to different processing procedures, automatically change the machine tool spindle speed, feed speed, and the movement track of the tool relative to the workpiece and other auxiliary functions. Complete the processing of multiple processes on multiple surfaces of the workpiece. And there are multiple tool changing or tool selection functions, so that the production efficiency is greatly improved.

The suction cup of the exposure machine is an important part of processing semiconductor chips. The product has high requirements on flatness, and it cannot meet the assembly requirements without precision machining. When the customer uses the horizontal machining center, he cannot change the factory parameter settings of the machine tool at will, because these factory parameter settings are directly related to the dynamic characteristics of each component of the horizontal machining center, and only the gap compensation parameter value can be set according to the actual situation.

The HMC/HLC series horizontal machining center produced by Shanghai Ants Machinery Equipment Co., Ltd. adopts four-axis three-linkage, adopts an inverted T-shaped structure, an integrated base, an integrated structure of the front bed and the base, and each linear coordinate guide rail is heavy. Carrying high-precision roller-type line rails, the deformation of the spindle system is small, and the machining accuracy is high. The workbench can rotate automatically and is equipped with an automatic tool change structure, which is widely used in the processing needs of construction machinery, petrochemical industry, coal machine parts, high-voltage substation and other fields. In addition, the APC series is equipped with a high-precision rotary double-exchange table, a high-rigidity roller linear guideway, a large guideway span, good overall rigidity of the machine tool, and strong bearing capacity; it is suitable for processing polyhedral parts such as boxes, machine bases, and columns. , It can realize the rough and finish machining of milling, boring, tapping and other multi-processes in one clamping, ensuring the precision requirements of the parts. The double workbench can greatly save the clamping time of the workpiece and improve the efficiency of the machine tool.

For details, please refer to the product details or contact our sales staff

E-mail: contact@antsmachine.com