Recently, our company successfully 1 set of Leaser Cutter, Laser Welding Machine and Press Brake to Armenia. Those equipment already is delivered to the client’s factory now. Client is very happy and satisfied to work with ANTISHICNC team.

| Producer | Shanghai ANTS Machine Equipment Co.,LTD | Brand | ANTISHICNC | Origin country | Shanghai, China | |

| Product Name | Laser Cutting Machine, Laser Welding Machine, Press Brake | Model No. | AT-3015 3000w

AT-3000w WC67K-125T2500 |

Export Country | Armenia | |

| Customer Introduction | The customer is a local metal processing plant with a wide range of business, including metal cutting, bending, welding, surface treatment, etc. The products are used in machinery manufacturing, automobiles, construction and other fields. The customer’s business is currently in the expansion stage and needs to expand the plant and add new equipment. | |||||

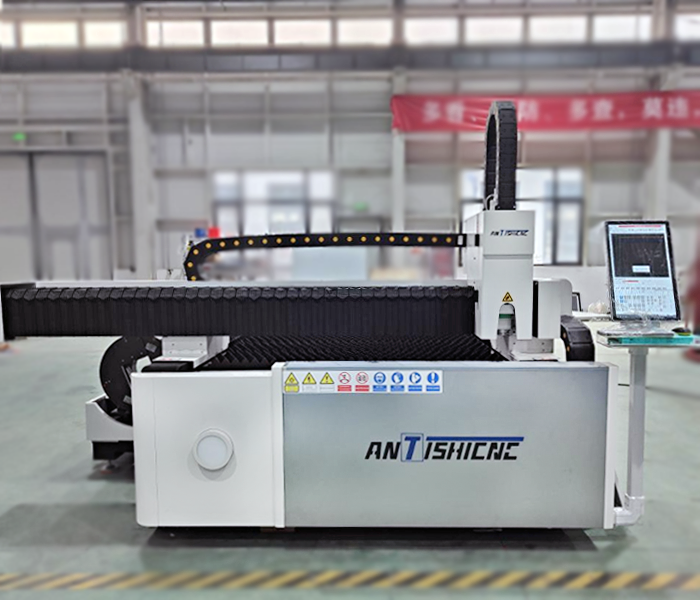

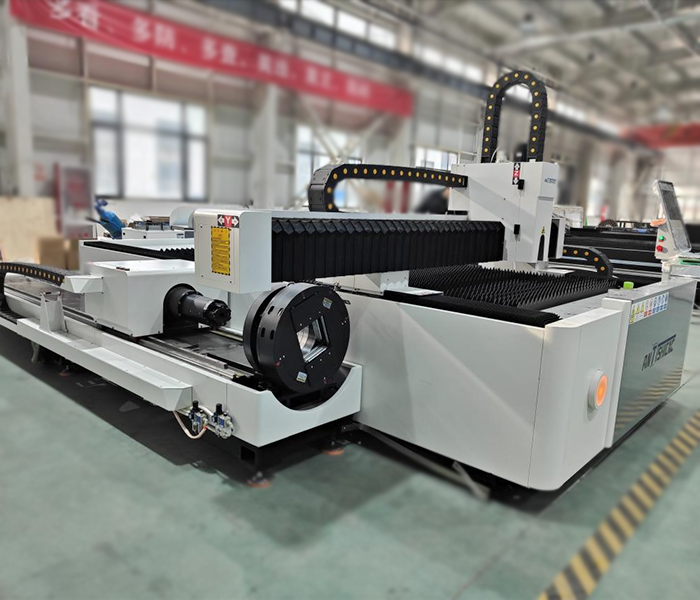

| Equipment Introduction | AT-3015 3000w Plate and tube laser cutting machine

1. Supports bevel cutting and double chuck clamping, suitable for all kinds of irregular pipe fittings. 2. Flexible track has strong adaptability to rough steel pipes and deformation; highly integrated, long service life, and efficient energy-saving design can greatly save costs. 3. Integrates plate cutting and tube cutting, can process all kinds of metal materials and various pipe fittings and plates; fully intelligent CNC system, simple operation. |

|||||

| Equipment Picture 1 |

|

|||||

|

|

|||||

| Equipment Introduction 2 | AT-3000W Laser Welding Machine

1. High degree of automation, simple welding process. 2. The non-contact operation method can meet the requirements of clean and environmental protection. 3. Improve work efficiency, the finished workpiece appearance is beautiful, the weld is small, the welding depth is large, the welding quality is high. |

|||||

| Equipment Picture 2 |

|

|||||

|

|

|||||

| Equipment Introduction3 | WC67K-125T2500 Press Brake

1. Adopt all-steel welded structure, with sufficient strength and rigidity; 2. Hydraulic upper transmission, stable and reliable; 3. Mechanical stop, torsion axis synchronization, high precision; 4. The back gauge and the stroke of the slider are electrically adjusted ; 5. Deflection compensation mechanism is optional to ensure higherbending accuracy; 6. CNC system TP10S,DA41T,E300PCT8 Optional 7. Y-axis and X-axis double servo automatic control,high accuracy |

|||||

| Equipment Picture 3 |

|

|

||||

| Package and shipping |  |

|

||||

If you want to order the similar machine, please contact with ANTISHICNC team!