For new energy vehicles in the core parts – lithium battery manufacturing, laser technology is once again agreed by the industry for the optimization of manufacturing methods, laser technology in lithium battery processing in the end what are the advantages? This article will provide you with a shallow analysis.

| Laser cutting | Laser welding | Laser cleaning | Laser marking |

|

|

|

|

New energy vehicles accelerate the development of lithium batteries become the core key

The concept of new energy vehicles has repeatedly swept through the capital market, attracting widespread attention from consumers and drawing the attention of industry giants. With the introduction of the concept of ‘carbon peak, carbon neutral’ and other concepts, new energy vehicles is not only a new concept of transport, but also an important way to achieve ‘green water and green mountains’, in the future, new energy vehicles will have a huge market potential to be tapped.

New energy vehicles include hybrid electric vehicles (HEVs) and fuel cell electric vehicles (FCEVs). However, nowadays, new energy vehicles generally only refer to pure electric vehicle route, that is, we are familiar with Tesla and a group of new car-making forces. The core component of a pure electric vehicle is the lithium battery.

As a new type of clean energy, lithium battery can not only provide power for new energy vehicles, but also for electric trains, electric bicycles, golf carts and other types of products. The production of lithium batteries is closely liaised by one process step after another, and its production process roughly includes three parts, namely, pole manufacturing, cell production and battery assembly. Therefore, the quality of lithium battery directly determines the performance of new energy vehicles, which puts forward strict requirements on its manufacturing technology and equipment. As an advanced ‘light’ manufacturing tool, laser technology, represented by laser welding and cutting, has demonstrated the features of high efficiency, precision, flexibility, reliability and stability, small loss of welding consumables, automation and high degree of safety, and has been widely used in the process of power lithium battery.

The application of laser processing technology in the field of new energy lithium battery

1.Laser cutting

Lithium battery processing on the accuracy, controllability and processing machine quality requirements are relatively high, before the emergence of laser technology, the lithium battery industry usually use traditional machinery for processing and cutting, but the traditional die-cutting knife equipment in the use of the process, it will inevitably wear and tear, dust fall and produce burrs, which may in turn lead to the overheating of the battery, short-circuit, or even explosion and other types of dangerous problems.

In order to avoid the danger, the use of laser cutting is more suitable. Compared with traditional mechanical cutting, laser cutting has the advantages of no tool wear, flexible cutting shape, edge quality control, higher accuracy and lower operating costs, which is conducive to reducing manufacturing costs, improve production efficiency, and significantly shorten the cycle of die-cutting new products. As a core component of new energy vehicles, lithium battery directly determines the performance of the whole vehicle. With the gradual explosion of the new energy vehicle market, laser cutting will have great market potential in the future.

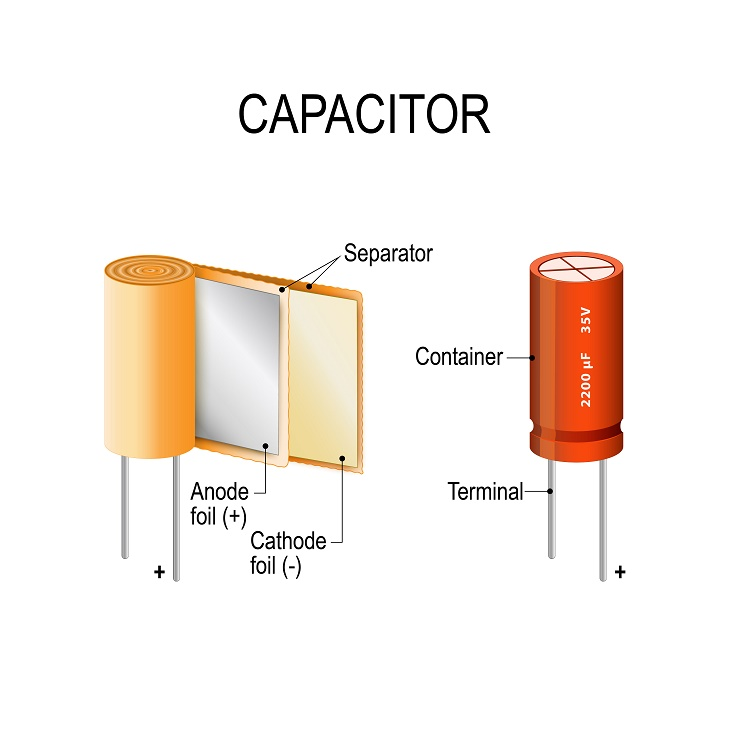

Lithium battery production steps is a typical ‘roll-to-roll’ process, need to go through from the film to a single battery and a single battery assembly into a battery system processing. A typical lithium battery has three layers of film – anode, barrier and cathode – as shown in the figure below.

The electrode coating is typically 100 μm thick and the separator film is 50 μm. The anode film is a graphite-coated copper film, the cathode film is an aluminium film coated with lithium metal oxides, and the separator film is made of polypropylene and polyethylene. Lithium battery production process:

Foil slitting, foil cutting and separator foil cutting, where the cutting process is applied, are more suitable for laser processing due to the high demands on precision, controllability and quality of the processing machine.

Foil Slitting

Foil slitting is the process of cutting a roll of foil into thin strips along the long edges according to the design of the cell. An infrared pulsed laser is suitable for this process and can slit the electrode coating at high speed and with high quality. Pulsed green and ultraviolet light can also be considered if more precision is required in terms of slitting width and quality.

Foil cutting

Foil cutting is the process of cutting long, thin strips of anode and cathode films into the desired shapes, taking into account the design of the battery. Depending on the cell design and whether the foil rolls are fully coated or not, the beam can be selected or adjusted so that it cuts the coating or only the foil. The laser used for this process is the same as that used for the aluminium foil slitting process.

Separator foil cutting

Similar to aluminium foil cutting, the cover film is cut to the desired shape with reference to the cell design. Since the separator foil consists of organic compounds, a pulsed UV laser is the most suitable choice.

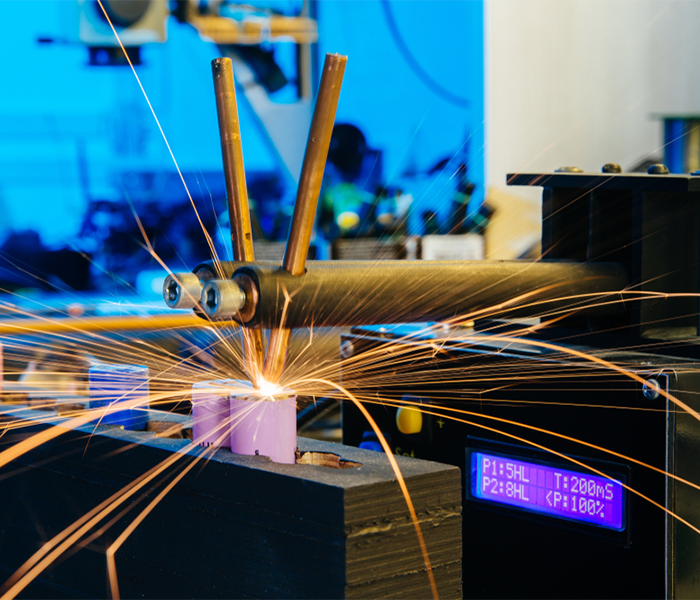

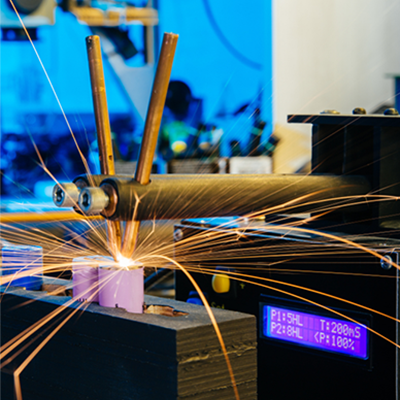

2.Laser welding

A lithium battery production has more than a dozen steps, and the role of the laser welding machine is to provide customers with a complete set of lithium battery production equipment, to ensure that the battery in the operation of the mileage and safety. Compared with the traditional argon arc welding, resistance welding and other methods, ultrasonic welding laser welding has significant advantages: one is a small heat-affected zone, the second is non-contact processing, and the third is high processing efficiency. From the laser welding point of view, the main welding materials for lithium batteries include aluminium alloy and copper alloy. The shape of the battery shell is mainly divided into square and cylindrical. At present, the popularity of square batteries in China is relatively high. Welding methods mainly include splicing welding and stack welding. In the field of new energy lithium battery, laser welding technology has been used on a large scale for welding of pole lugs, cell shells, sealing pegs, flexible connections, explosion-proof valves, battery modules and so on.

Laser welding energy concentration, high welding efficiency, high processing precision, weld depth and width ratio. The laser beam is easy to focus, align and be guided by optical instruments, can be placed at a suitable distance from the work-piece, and then guided by fixtures or barriers around the work-piece. The heat input of the laser beam in the working process is small, the heat-affected zone is small, the residual stress and deformation of the work-piece is small, and precise welding can be achieved. As the power battery cell follows the principle of ‘lightweight’, its material is generally aluminium alloy and thin, so the general shell, cover and bottom are basically required to reach 1.0 mm or less. Currently, the thickness of the basic material of mainstream manufacturers is around 0.8 mm, and in order to weld these thin pieces together, it is very necessary to use laser welding.

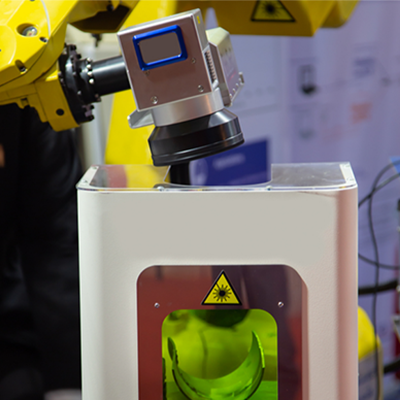

3.Laser cleaning

The manufacturing of lithium battery includes three parts: pole piece manufacturing, cell manufacturing and battery assembly. Increasing laser cleaning in the three processes can greatly improve the level of battery manufacturing process.

Laser cleaning before electrode coating

Positive and negative electrode of lithium battery is coated with lithium battery positive and negative materials on the metal strip, metal strip in the coating of electrode materials, the need to clean the metal strip, the metal strip is generally thin aluminium or copper thin, the original wet ethanol cleaning, it is easy to lithium battery damage to other parts. Laser dry cleaning machine can effectively solve the above problems.

Laser cleaning before battery welding

The use of pulsed laser direct radiation decontamination, so that the surface temperature rises and thermal expansion occurs, thermal expansion of pollutants or substrate vibration, so that the pollutants to overcome the surface adsorption force off the surface of the substrate so as to achieve the purpose of removing the surface of the object stains. This way can effectively remove the dirt, dust, etc. on the end surface of the pole pole of the electric core, and prepare for the battery welding in advance, in order to reduce the defective products of welding.

Laser cleaning during battery assembly

In order to prevent lithium battery safety accidents, generally need to lithium battery cell external adhesive treatment, in order to play the role of insulation, to prevent the occurrence of short-circuit as well as to protect the line, to prevent scratching. Insulation board, end plate laser cleaning, cleaning the surface of the core dirt, roughening the surface of the core, to improve the adhesion of the adhesive or glue, and cleaning will not produce harmful pollutants, belonging to the environmental protection of the green cleaning method, which is highly concerned about the environmental protection of the world more and more show its importance.

Tab cleaning

In some cases, graphite and lithium metal oxides need to be removed to reveal bare copper or aluminium foil labels. The key to this step is to remove the coated material without damaging the metal foil underneath. The appropriate technology for this part of the process is a pulsed infrared laser.

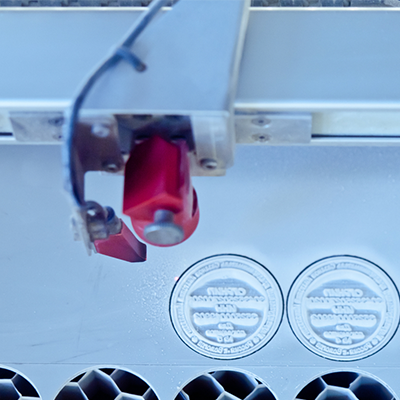

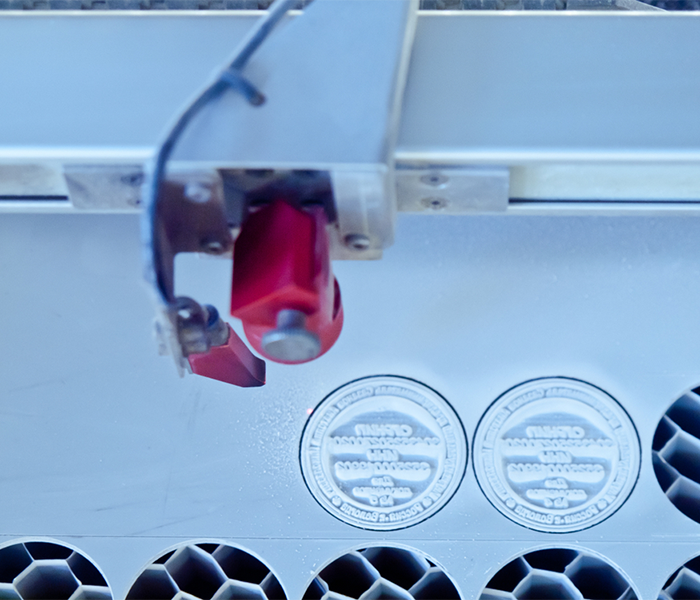

4.Laser marking

Laser marking speed, high production efficiency, presenting good results, so it is also gradually applied to the production and processing of lithium batteries, and long service life of the equipment, easy to operate, no consumables, can effectively save costs and labour costs. In the processing of lithium batteries, you can use the laser on the surface of the code, characters, date of production, anti-counterfeiting code and other information, not only will not hurt the lithium batteries, but also to enhance the overall aesthetics of the battery. Laser marking is characterized by non-contact, able to print and mark in any regular or irregular object appearance, the work-piece after being marked, will not produce internal stress and deformation, not only to ensure the original accuracy of the work-piece, but also will not cause corrosion, wear and tear, toxicity and pollution of the surface layer, greatly enhancing the processing efficiency.

If you have the need of laser cutting and welding, welcome to consult Shanghai ANTISHICNC. We have rich experience in manufacturing and applying laser machines, and can provide professional technical support for you.

Keywords: laser cutting, laser welding, laser cleaning, laser marking