X-axis of CNC lathe

The X-axis in a CNC lathe is responsible for the lateral movement of the workpiece. The X-axis is based on the center line of the workpiece, and its positive direction is to the right. The movement of the X-axis is driven by an AC servo motor, which can be precisely positioned to achieve high-speed movement and high-precision processing.

Z axis of CNC lathe

The Z axis is the longitudinal axis in the CNC lathe, and its position is based on the cutting blade clamped on the tool post of the spindle as the reference point. The direction of the Z-axis is towards the processing rotation axis or the axis of the workpiece. It is driven by the cutting pressure of the motor and can control the processing depth. The Z axis can also be used to control the diameter of the workpiece, for example, in turning operations, it can control the overcut, depth of cut and radius of the workpiece.

On a CNC lathe, the X-axis and Z-axis cooperate with each other and operate simultaneously. Their positional relationship depends on the shape and material of the workpiece. During the machining process, programmers control the machining trajectory through high-quality encoders to achieve high-precision machining requirements.

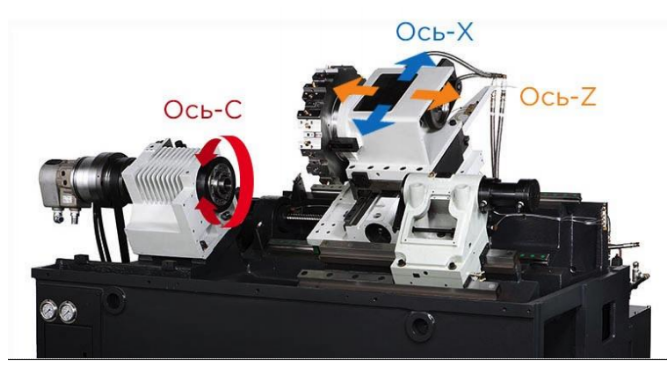

In short, the two most important axes in a CNC lathe are the X-axis and the Z-axis. Their cooperation and precise movements can enable CNC lathes to achieve processing levels that surpass traditional lathes in terms of high speed, high precision, and high efficiency. At the same time, the CNC turning and milling compound machine has the function of spindle indexing, which is what we usually call the C axis, which can realize the control of various angles and is used to mill various complex workpieces. As shown in Figure 1 below.

Figure 1: Axial Description of CNC Turning and Milling Machine

So how to judge the axis of CNC milling machine and five-axis machining center?

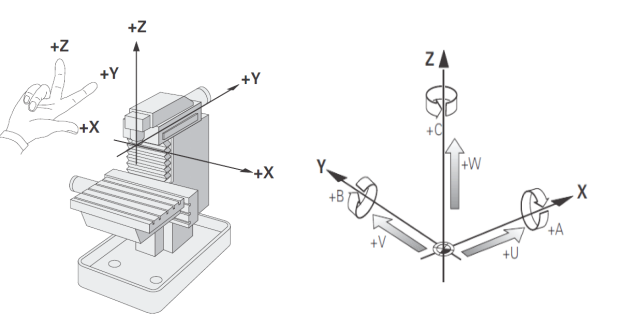

According to the Cartesian coordinate system, the linear direction and the direction of the rotation axis of the coordinate axis of the CNC machine tool can be judged.

CNC five-axis usually refers to three linear axes and two rotary axes, namely X, Y, and Z linear axes. The two rotation axes are A and B axes or two A and C axes or two B and C axes. my country’s standard JB3051-82 stipulates: The coordinate axes X, Y, and Z of the linear motion of the CNC machine tool are specified as the right-handed Cartesian coordinate system. (The ISO International Organization for Standardization also stipulates the use of the Cartesian coordinate system.) The direction of each axis is judged according to Figures 2 and 3 below.

| Figure 2: Right-hand Cartesian coordinate system method to determine axial direction | Figure 3: Judgment of each axis of the five-axis CNC machining center |

|

|

ANTISHICNC is a leading manufacturer, distributor and exporter of industrial lathe machinery and machine tool equipment in China. The company is headquartered in the center of Shanghai. Since the establishment of the company, relying on strong location advantages and talent advantages, it has continuously promoted China’s manufacturing to explore higher and deeper fields; it has continuously promoted China’s top lathe machinery and equipment enterprises and their products to the international market;

Keywords: CNC lathe, machining center, five-axis turning and milling machine