Equipment Introductions

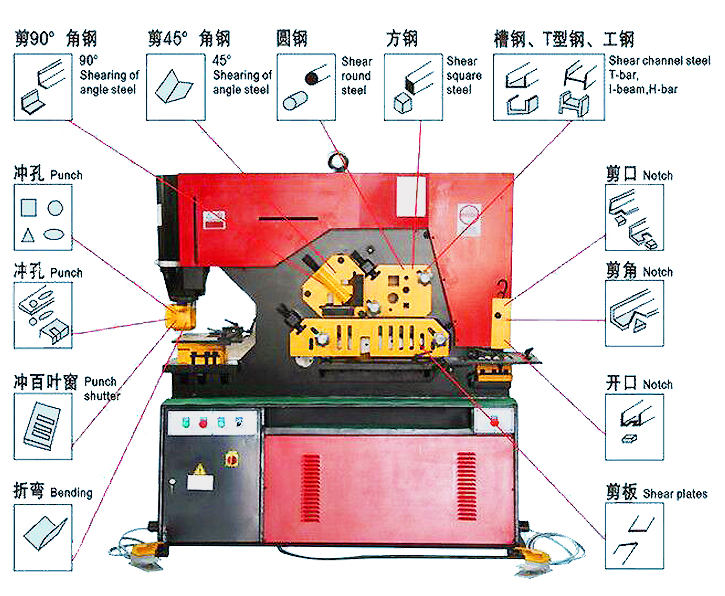

Q35Y series industrial-grade hydraulic ironworker machine featuring multiple functions, including: round hole, square hole, oblong hole punching; steel plate, flat bar, angle steel, C-channel, H-beam punching; steel plate bending; angle steel shearing, notching and bending; flat, round, square bar, C-channel, I-beam, T-bar shearing/cutting; angle bending and pipe notching.

Features

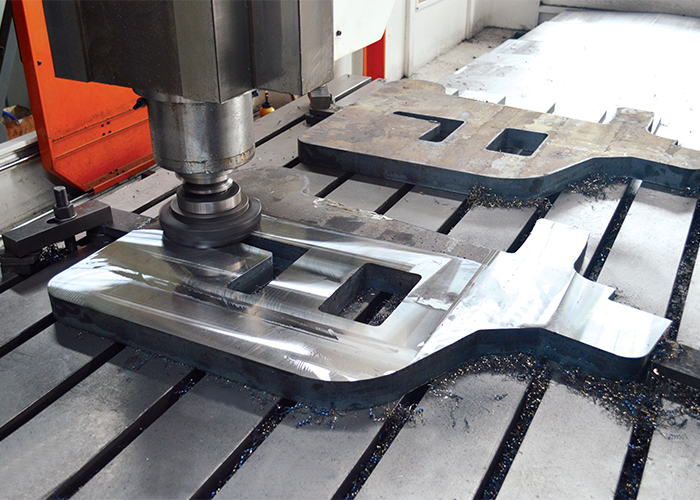

1.Professionally engineered design frame structures

2.Steel welds with high precision strength and rigidity to eliminate vibrations

3.Ironworker steel frame Q345

4.Hydraulic fuel tanks and ironworker frame built by our Factory

5.Two hydraulic cylinders

6.Easy adjustable stroke control with ruler

7.Indicator on both hydraulic cylinders

8.Electric back gauge auto stop

9.Laser light alignment system for punch station.

10.Moveable working light

11.Hydraulic system with overload protection system

12.Large punching, notching, flat shearing table with ruler gauge

13.Emergency safety stop switch

14.Easy maintenance

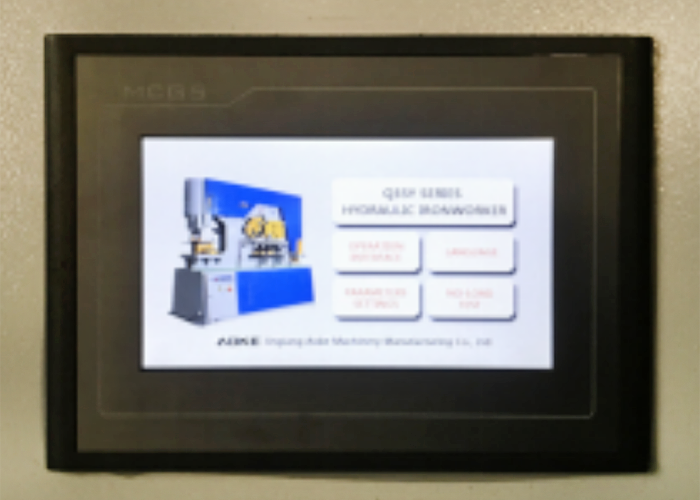

15.Intelligent Fault Identification System.

Technical parameter

| Model | Q35Y-40 | Q35Y-50 | |

| Process Capacity (T) | 200 | 250 | |

| Material Tensile Strength of work pieces (Mpa) | <=450 | ||

| Punching | Max. Capacity | Ø40 x 35 | Ø40 x 40 |

| Dia(Punch) x Thickness(mm) | Ø50 x 28 | Ø50 x 32 | |

| Max. Stroke Length (mm) | 80 | 80 | |

| Throat Depth (mm) | 600 | 600 | |

| Cycles /min. (Stroke Length) | 8/21 | 8/18 | |

| Flat Shearing | Max shearing size | 400 x 35 | 400 x 40 |

| (width * thickness) (mm) | 700 x 25 | 750 x 30 | |

| Angle Shearing | 45o | 100 x 10 | 120 x 10 |

| shearing (mm) | |||

| 90o shearing (mm) | 200 x 18 | 200 x 20 | |

| Bar Shearing | Round Bar/ Square Bar (mm) | 70/60 | 80/65 |

| Channel (mm) | 300 x 89 x 12 | 320 x 92 x 12 | |

| I beam steel (mm) | 300 x 126 x 11 | 320 x 130 x 10 | |

| Motor Power (KW) | 15 | 22 | |

| N.W (KG) | 7900 | 9500 | |

| Overall Dimension (mm) | 2860x1200x2400 | 3200x1520x2300 | |

| 1500x1400x1260 | |||

| Intelligent system: | YES | YES | |

Product reference picture

|

|

|

|

Standard Mold And Optional

Main standard properties components of Ironworker:

| No. | Parts | Origin |

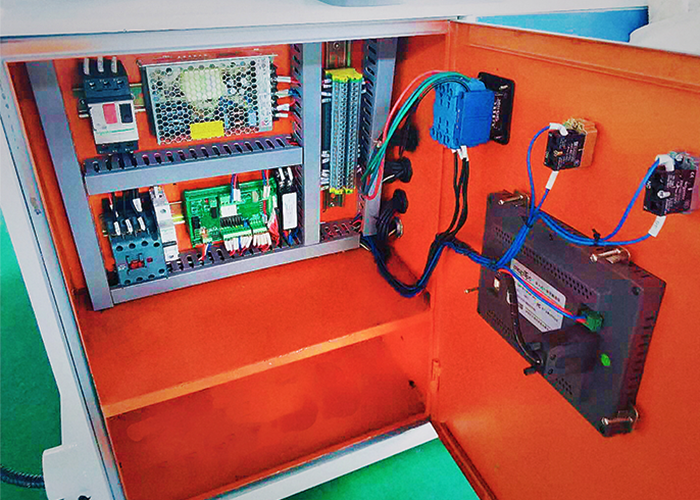

| 1 | Main Electrical Component | SCHNEIDER |

| 2 | Hydraulic Valve | CHINA |

| 3 | Hydraulic Pump | CHINA |

| 4 | Proximity Switch | SCHNEIDER |

| 5 | Timer Relay | SCHNEIDER |

| 6 | Hydraulic Oil Seal | Japan NOK |

| 7 | Touch screen | MCGS |

| 8 | Motor | CHINA |

The following 5 sets of moulds will be installed in machine:

1. A set of round hole punching die

2. A set of angle steel blade

3. A set of round and square bar blade

4. A set of shearing plate blade

5. A set of notching blade

If you need any more molds, then you need to send the details to us and extra cost.

Spare parts with machine:

1. Operation Manual

2. Test Certificate

3. Packing List

4. Key to the Interlocking Unit

5. Hook Shape Wrench

6. Hexagon key Wrench

7. Combined pad-ring

8. SF-2 Bearing of Compound bushing

9. Oil gun

Optional

| Round punch head

Square punch head Ellipse punch head |

I-beam mould

Channel mould T-beam mould |

Bending parts |

Video