Recently, a person in charge of a metal processing and forging equipment company from Uzbekistan purchased a CNC lathe CK6140 in our company. The company has been operating since 1993. Today, the company offers a full range of equipment supply services from equipment selection to the commissioning phase. Select the equipment with the functions and configuration best suited to the production task, and the company’s experts select the technical task (TOR) or production program according to the equipment. Execute complex equipment using tools and fixtures, then produce trial batches of parts. Ultimately, customers choose to cooperate with our company, ANTISHI provides customers with proven and reliable equipment that meets the best choice in terms of price and quality ratio.

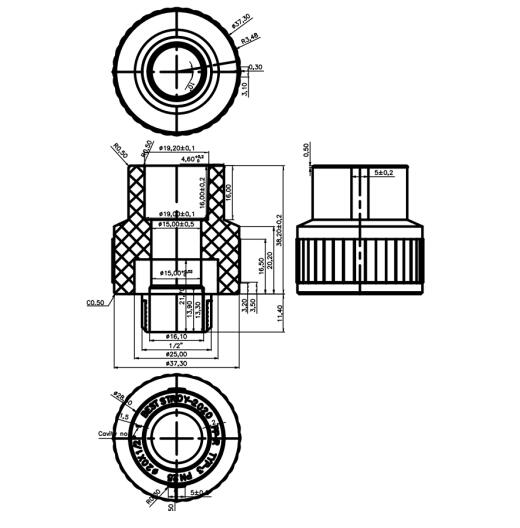

Customer requirements: process the inner and outer threads of the steel pipe, the maximum diameter is 110mm, and the maximum workpiece size is 150*150mm. The weight of the processed parts is 100G. The drawings are as follows:

At the request of the customer, a CNC lathe that can process internal and external threads is required. And the size of the workpiece to be processed is 150*150mm, the steel pipe is processed in a single piece, and the accuracy should not be lower than 0.1mm. The final customer chooses CK6140 CNC lathe for processing.

CK6140 CNC lathe can be used for semi-finishing and finishing of mechanical parts. It has reliable structure, convenient operation, economical application, and can meet the needs of many industries. CK6140 CNC lathe is especially suitable for high-efficiency, large-scale and high-precision turning of the inner and outer cylindrical surfaces, conical surfaces, threads, drilling, reaming, and curved revolving parts of shaft and disc parts. The product adopts the integrated structure of machine, electricity and liquid, and the overall layout is compact and reasonable, which is convenient for maintenance. The CNC control system adopted by the machine tool has comprehensive functions and reliable performance. The CNC systems used in this product include Guangshu 980TD system, Huazhong system, FANUC0I-MATE system, Siemens system, etc. The CNC lathe adopts reliable protection, safe operation of the machine tool, generous and pleasant appearance, and has a strong market demand and competitive advantage.

The main configuration of CK6140 CNC lathe is as follows:

1. Integral casting structure

The main components such as the bed base, bed body, and headboard are all cast from high-strength materials, and the machine tool has been used for a long time.

2. Three-jaw chuck

250mm manual three-jaw self-centering chuck precision chuck, automatic centering and clamping range, fast clamping speed.

3. Electric knife holder

4-station electric tool holder

4. Quenched rail

The quenching layer of the guide rail is deep, which can greatly enhance the service life, anti-wear degree and anti-damage hardness of the guide rail of the fuselage.

5. Brand electric control box

The layout of the electric control box is neat and reasonable, and the original complete set of motor drive lines are used neatly, and the maintenance is convenient.