1. Two Kinds of Machining for Drilling Holes

In general, when drilling materials on a drilling machine, the drill should perform two movements at the same time:

(1) The main motion, that is, the rotary motion of the drill bit around the axis (cutting motion);

(2) Auxiliary motion, that is, the linear motion of the drill bit along the axis direction against the workpiece (feed motion).

When drilling, due to the shortcomings of the structure of the drill bit, the workpiece processing quality will be affected to a certain extent. The processing accuracy is generally below IT10 level, and the surface roughness is about Ra12.5μm, which belongs to rough processing.

2. Operation Steps of Drilling(Drilling Machine,Milling Machine,Sawing Machine)

①. Marking: Before drilling, you should first be familiar with the requirements of the drawing. According to the position and size requirements of the drilling, use a height ruler to mark the cross center line of the hole position. The center line is vulgar, clear and accurate, and the thinner the better, after drawing The line should be checked later with a vernier caliper or steel ruler.

②. Draw the inspection square or inspection circle: After the line is drawn and the inspection is qualified, the inspection square or inspection circle with the center line of the hole as the symmetrical center should be drawn as the inspection line during the test drilling, so as to facilitate the drilling process. Check and correct drilling positions.

③. Proofing and punching: After drawing the corresponding inspection square or inspection circle, proofing and punching should be done carefully. First hit a small point, carefully observe in different directions of the center line of the cross to see if the sample punch is on the intersection of the center line of the cross.

④. Clamping: Wipe clean the machine table, fixture surface, and workpiece datum surface, and clamp the workpiece. The clamping is required to be flat and firm, which is convenient for observation and measurement. Attention should be paid to the clamping method of the workpiece to prevent the workpiece from being deformed due to clamping.

⑤. Test drilling: Test drilling must be done before drilling: align the chisel edge of the drill bit with the center of the hole and punch out a shallow pit, and then visually check whether the position of the shallow pit is correct, and constantly correct the deviation so that the shallow pit matches the inspection circle. coaxial. If the deviation is small, the workpiece can be pushed in the opposite direction of the deviation while tripping out to achieve gradual correction.

⑥. Drilling: The fitter’s drilling is generally dominated by manual feeding operations. When the test drilling meets the drilling position accuracy requirements, drilling can be carried out. During manual feeding, the feeding force should not cause the drill bit to bend, so as to avoid skewing the axis of the hole.

3. Methods to improve drilling accuracy(Drilling Machine,Milling Machine,Sawing Machine)

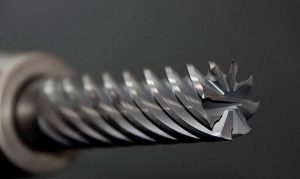

①. Sharpening the drill bit is the premise

Before drilling, the corresponding drill should be selected for sharpening. In addition to maintaining the correct top angle, clearance angle and chisel bevel angle of the sharpened drill bit, the length of the two main cutting edges is equal and symmetrical with the center line of the drill bit, and the two main flank surfaces are smooth, in order to facilitate centering and reduce the roughness of the hole wall. , and the chisel edge and main cutting edge should be properly ground (preferably rough grinding on the grinder first, and then finishing on the oil stone).

②. Accurate scribing is the foundation

When scribing accurately with a height ruler, the correct size should be ensured first. When scribing, an angle of 40 to 60 degrees (along the scribing direction) is formed between the scribing needle angle and the scribing plane of the workpiece, so that the scribing lines are clear and uniform. Pay attention to the selection of the scribed datum surface, the datum surface should be processed accurately, and the flatness of itself and the perpendicularity to the adjacent surface should be guaranteed. After the cross line of the hole position is drawn, in order to ensure easy alignment when drilling, use the center punch to punch out the center point on the cross line (requires that the punch point should be small and the position should be accurate).

③. Correct clamping is the key

Under normal circumstances, for holes with a diameter less than 6mm, if the accuracy is not high, the workpiece can be clamped with hand pliers for drilling; for holes of 6-10mm, if the workpiece is regular and flat, it can be clamped with a flat-nose pliers, but the surface of the workpiece should be clamped. Perpendicular to the drill spindle. When drilling a hole with a larger diameter, the pliers must be fixed with a bolt pressing plate; for a large workpiece and the hole diameter is more than 10mm, the method of clamping the pressing plate should be used for drilling.

④. Accurately finding is the point

After the workpiece is clamped, don’t rush to drop the drill, it should be aligned first. Alignment includes static alignment and dynamic alignment. The so-called static alignment refers to alignment before the drilling machine is started, so that the center line of the drilling machine spindle and the intersection of the workpiece cross line are aligned. This method is safe and convenient for beginners, and it is easier to master, but because for example, the swing of the drilling machine spindle is not considered. and other uncertain factors, the drilling accuracy is low. Dynamic alignment is performed after the drilling machine is started. While alignment, some uncertain factors are taken into account, and the accuracy is relatively high.

⑤. Serious testing is essential

The detection can accurately and timely find the accuracy of the hole, so that the necessary measures can be taken to remediate. For holes with high drilling accuracy, we generally adopt the processing technology of drilling, reaming and reaming. After drilling the small hole in the first step, use a caliper to detect the error offset from the center of the bottom hole to the reference plane, and convert the position between the bottom hole and the ideal center after actual measurement. Properly increase the top angle of the drill bit, weaken the automatic centering effect, push the workpiece in the positive direction, and gradually increase the diameter of the drill tip to remedy. If the error is greater than 0.10mm, the two side walls of the bottom hole can be trimmed with assorted round files, and the trimmed part should be connected with the smooth transition of the bottom hole arc.