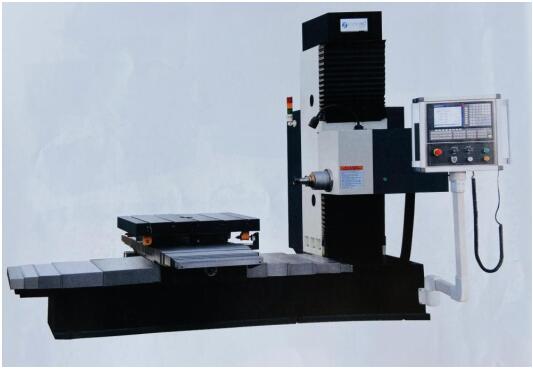

1. Installation of CNC milling machine: The general CNC milling machine is a mechatronics design. From the factory to the user, it is shipped as a whole machine without disassembly and packaging. Therefore, after receiving the machine tool, the user only needs to follow the instructions in th...... [Read More]

CNC milling machine assembly method?

Reported by: ANTISHICNC Date: November 12, 2021